Are you a seasoned Carbon Furnace Operator seeking a new career path? Discover our professionally built Carbon Furnace Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

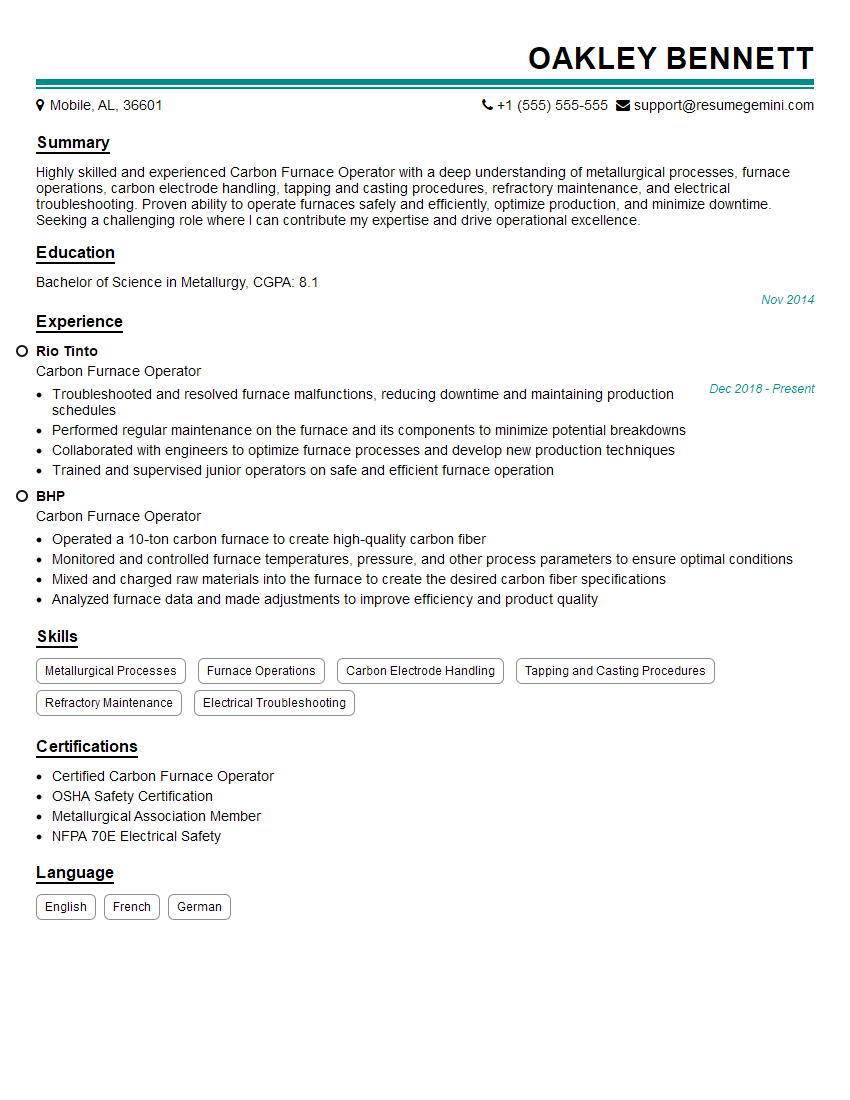

Oakley Bennett

Carbon Furnace Operator

Summary

Highly skilled and experienced Carbon Furnace Operator with a deep understanding of metallurgical processes, furnace operations, carbon electrode handling, tapping and casting procedures, refractory maintenance, and electrical troubleshooting. Proven ability to operate furnaces safely and efficiently, optimize production, and minimize downtime. Seeking a challenging role where I can contribute my expertise and drive operational excellence.

Education

Bachelor of Science in Metallurgy

November 2014

Skills

- Metallurgical Processes

- Furnace Operations

- Carbon Electrode Handling

- Tapping and Casting Procedures

- Refractory Maintenance

- Electrical Troubleshooting

Work Experience

Carbon Furnace Operator

- Troubleshooted and resolved furnace malfunctions, reducing downtime and maintaining production schedules

- Performed regular maintenance on the furnace and its components to minimize potential breakdowns

- Collaborated with engineers to optimize furnace processes and develop new production techniques

- Trained and supervised junior operators on safe and efficient furnace operation

Carbon Furnace Operator

- Operated a 10-ton carbon furnace to create high-quality carbon fiber

- Monitored and controlled furnace temperatures, pressure, and other process parameters to ensure optimal conditions

- Mixed and charged raw materials into the furnace to create the desired carbon fiber specifications

- Analyzed furnace data and made adjustments to improve efficiency and product quality

Certificates

- Certified Carbon Furnace Operator

- OSHA Safety Certification

- Metallurgical Association Member

- NFPA 70E Electrical Safety

Languages

- English

- French

- German

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Carbon Furnace Operator

- Highlight your technical skills and experience in metallurgical processes and furnace operations.

- Quantify your accomplishments and provide specific examples of how you have improved efficiency or reduced downtime.

- Demonstrate your understanding of safety protocols and your commitment to maintaining a safe work environment.

- Tailor your resume to the specific requirements of the job you are applying for.

- Proofread your resume carefully for any errors in grammar or spelling.

Essential Experience Highlights for a Strong Carbon Furnace Operator Resume

- Operate carbon furnaces to produce high-quality steel and other metals.

- Monitor and control furnace temperature, pressure, and other process parameters to ensure optimal performance.

- Handle and replace carbon electrodes, ensuring proper alignment and electrical contact.

- Perform tapping and casting operations to extract molten metal from the furnace.

- Maintain refractory linings and other furnace components to prevent damage and ensure efficient operation.

- Troubleshoot and resolve electrical and mechanical issues to minimize downtime and maintain production.

- Adhere to safety protocols and maintain a clean and organized work area.

Frequently Asked Questions (FAQ’s) For Carbon Furnace Operator

What are the key skills required to be a successful Carbon Furnace Operator?

The key skills for a successful Carbon Furnace Operator include a strong understanding of metallurgical processes, furnace operations, carbon electrode handling, tapping and casting procedures, refractory maintenance, and electrical troubleshooting.

What are the day-to-day responsibilities of a Carbon Furnace Operator?

The day-to-day responsibilities of a Carbon Furnace Operator include operating furnaces, monitoring and controlling process parameters, handling and replacing carbon electrodes, performing tapping and casting operations, maintaining refractory linings, troubleshooting electrical and mechanical issues, and adhering to safety protocols.

What are the career prospects for a Carbon Furnace Operator?

The career prospects for a Carbon Furnace Operator are good, with opportunities for advancement to supervisory or management roles. With experience and additional training, Carbon Furnace Operators can also move into related fields such as metallurgy or engineering.

What are the educational requirements to become a Carbon Furnace Operator?

The minimum educational requirement to become a Carbon Furnace Operator is typically a high school diploma or equivalent. However, some employers may prefer candidates with a post-secondary degree in metallurgy or a related field.

What are the certification or licensing requirements to become a Carbon Furnace Operator?

There are no specific certification or licensing requirements to become a Carbon Furnace Operator. However, some employers may require candidates to have experience in a related field, such as welding or electrical work.

What is the work environment like for a Carbon Furnace Operator?

Carbon Furnace Operators typically work in industrial settings, such as steel mills or foundries. The work can be physically demanding and may involve exposure to heat, noise, and dust.

What are the safety precautions that Carbon Furnace Operators must take?

Carbon Furnace Operators must wear personal protective equipment, such as gloves, safety glasses, and respirators. They must also be aware of the potential hazards of working with high temperatures and molten metal.