Are you a seasoned Carbonation Equipment Operator seeking a new career path? Discover our professionally built Carbonation Equipment Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

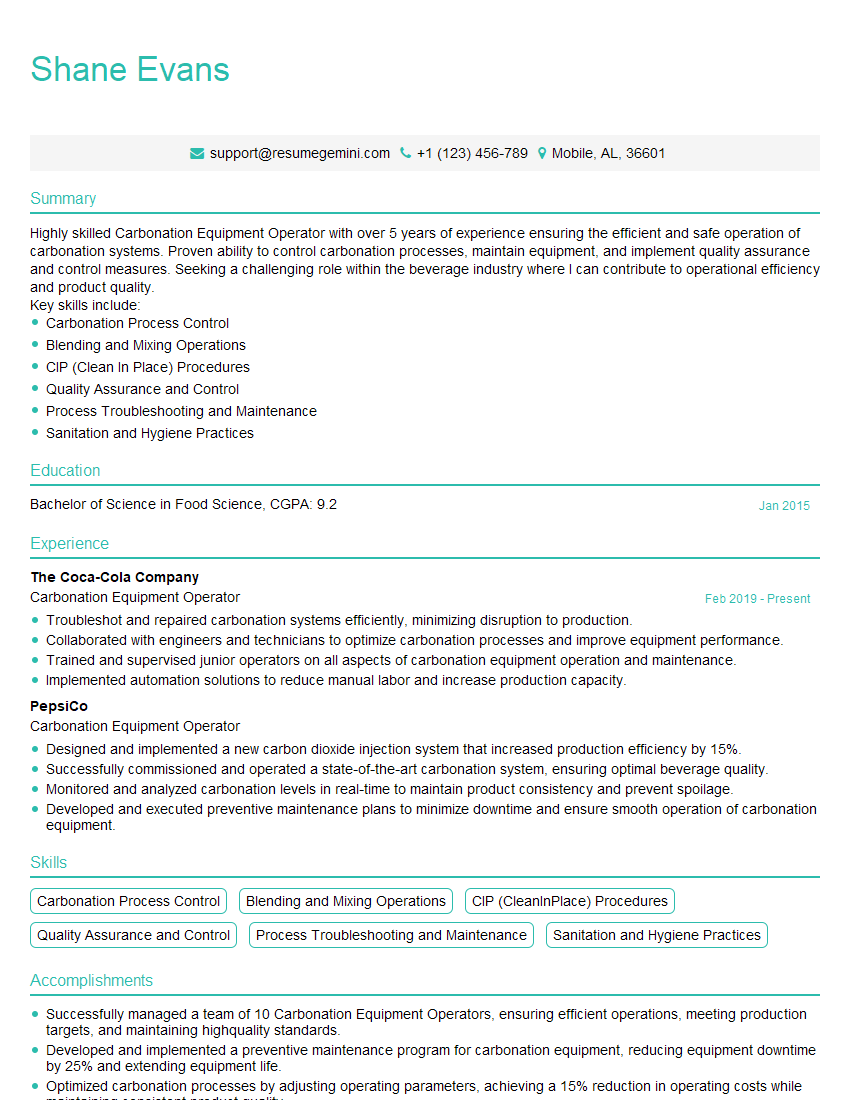

Shane Evans

Carbonation Equipment Operator

Summary

Highly skilled Carbonation Equipment Operator with over 5 years of experience ensuring the efficient and safe operation of carbonation systems. Proven ability to control carbonation processes, maintain equipment, and implement quality assurance and control measures. Seeking a challenging role within the beverage industry where I can contribute to operational efficiency and product quality.

Key skills include:

- Carbonation Process Control

- Blending and Mixing Operations

- CIP (Clean In Place) Procedures

- Quality Assurance and Control

- Process Troubleshooting and Maintenance

- Sanitation and Hygiene Practices

Education

Bachelor of Science in Food Science

January 2015

Skills

- Carbonation Process Control

- Blending and Mixing Operations

- CIP (CleanInPlace) Procedures

- Quality Assurance and Control

- Process Troubleshooting and Maintenance

- Sanitation and Hygiene Practices

Work Experience

Carbonation Equipment Operator

- Troubleshot and repaired carbonation systems efficiently, minimizing disruption to production.

- Collaborated with engineers and technicians to optimize carbonation processes and improve equipment performance.

- Trained and supervised junior operators on all aspects of carbonation equipment operation and maintenance.

- Implemented automation solutions to reduce manual labor and increase production capacity.

Carbonation Equipment Operator

- Designed and implemented a new carbon dioxide injection system that increased production efficiency by 15%.

- Successfully commissioned and operated a state-of-the-art carbonation system, ensuring optimal beverage quality.

- Monitored and analyzed carbonation levels in real-time to maintain product consistency and prevent spoilage.

- Developed and executed preventive maintenance plans to minimize downtime and ensure smooth operation of carbonation equipment.

Accomplishments

- Successfully managed a team of 10 Carbonation Equipment Operators, ensuring efficient operations, meeting production targets, and maintaining highquality standards.

- Developed and implemented a preventive maintenance program for carbonation equipment, reducing equipment downtime by 25% and extending equipment life.

- Optimized carbonation processes by adjusting operating parameters, achieving a 15% reduction in operating costs while maintaining consistent product quality.

- Collaborated with engineers to design and implement a new carbonation system, resulting in increased production capacity and improved product consistency.

- Successfully troubleshooted and resolved a major equipment malfunction, preventing production downtime and minimizing financial losses.

Awards

- Received the Carbonation Equipment Operator of the Year award for 2023, recognizing exceptional performance and contributions to the field.

- Honored with the Safety Excellence Award for maintaining an exemplary safety record and promoting workplace safety practices.

- Recognized with the Innovation Award for developing and implementing a novel carbonation process, resulting in increased efficiency and product quality.

Certificates

- Carbonation Equipment Operator Certification

- Food Safety and Sanitation Certification

- ISO 90012015 Quality Management Certification

- First Aid and CPR Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Carbonation Equipment Operator

- Quantify your accomplishments with specific metrics whenever possible.

- Highlight your experience with specific carbonation equipment and processes.

- Emphasize your understanding of quality assurance and control principles.

- Showcase your ability to work effectively in a team environment.

Essential Experience Highlights for a Strong Carbonation Equipment Operator Resume

- Monitoring and controlling carbonation processes to ensure optimal levels of carbonation in beverages.

- Operating and maintaining carbonation equipment, including compressors, chillers, and filters.

- Performing CIP (Clean In Place) procedures to maintain equipment sanitation and hygiene.

- Conducting quality assurance checks to ensure the carbonation levels and other beverage parameters meet specifications.

- Troubleshooting and resolving process issues to maintain efficient operation and product quality.

- Maintaining a safe and clean work environment by adhering to sanitation and hygiene practices.

Frequently Asked Questions (FAQ’s) For Carbonation Equipment Operator

What is the role of a Carbonation Equipment Operator?

A Carbonation Equipment Operator is responsible for operating and maintaining carbonation systems to ensure the production of high-quality carbonated beverages. Their duties include monitoring and controlling carbonation levels, maintaining equipment, implementing quality assurance measures, and troubleshooting process issues.

What skills are required to be a successful Carbonation Equipment Operator?

Successful Carbonation Equipment Operators typically possess a combination of technical skills, such as knowledge of carbonation processes and equipment maintenance, as well as soft skills, such as attention to detail, problem-solving abilities, and teamwork.

What is the career path for a Carbonation Equipment Operator?

Carbonation Equipment Operators can advance their careers by gaining experience and developing specialized skills. They may become supervisors or managers responsible for overseeing carbonation operations or move into related roles in the beverage industry, such as quality control or production management.

What are the challenges faced by Carbonation Equipment Operators?

Carbonation Equipment Operators may face challenges related to maintaining optimal carbonation levels, ensuring equipment reliability, and adhering to strict quality and safety standards. Additionally, they may need to work in demanding environments with potential exposure to hazardous substances.

How can I prepare for a career as a Carbonation Equipment Operator?

Aspiring Carbonation Equipment Operators can prepare for a career in this field by pursuing a degree or certification in a related field, such as food science or engineering. They can also gain practical experience through internships or entry-level positions in the beverage industry.