Are you a seasoned Caustic Liquor Maker seeking a new career path? Discover our professionally built Caustic Liquor Maker Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

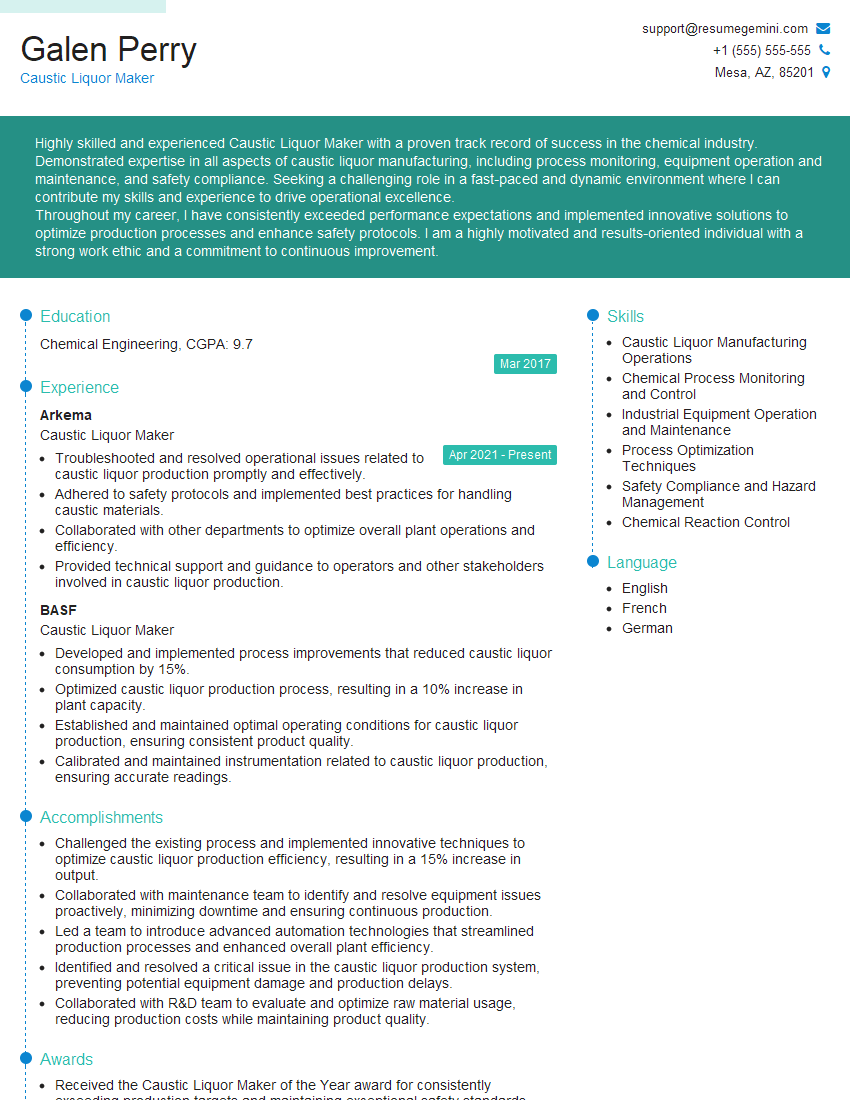

Galen Perry

Caustic Liquor Maker

Summary

Highly skilled and experienced Caustic Liquor Maker with a proven track record of success in the chemical industry. Demonstrated expertise in all aspects of caustic liquor manufacturing, including process monitoring, equipment operation and maintenance, and safety compliance. Seeking a challenging role in a fast-paced and dynamic environment where I can contribute my skills and experience to drive operational excellence.

Throughout my career, I have consistently exceeded performance expectations and implemented innovative solutions to optimize production processes and enhance safety protocols. I am a highly motivated and results-oriented individual with a strong work ethic and a commitment to continuous improvement.

Education

Chemical Engineering

March 2017

Skills

- Caustic Liquor Manufacturing Operations

- Chemical Process Monitoring and Control

- Industrial Equipment Operation and Maintenance

- Process Optimization Techniques

- Safety Compliance and Hazard Management

- Chemical Reaction Control

Work Experience

Caustic Liquor Maker

- Troubleshooted and resolved operational issues related to caustic liquor production promptly and effectively.

- Adhered to safety protocols and implemented best practices for handling caustic materials.

- Collaborated with other departments to optimize overall plant operations and efficiency.

- Provided technical support and guidance to operators and other stakeholders involved in caustic liquor production.

Caustic Liquor Maker

- Developed and implemented process improvements that reduced caustic liquor consumption by 15%.

- Optimized caustic liquor production process, resulting in a 10% increase in plant capacity.

- Established and maintained optimal operating conditions for caustic liquor production, ensuring consistent product quality.

- Calibrated and maintained instrumentation related to caustic liquor production, ensuring accurate readings.

Accomplishments

- Challenged the existing process and implemented innovative techniques to optimize caustic liquor production efficiency, resulting in a 15% increase in output.

- Collaborated with maintenance team to identify and resolve equipment issues proactively, minimizing downtime and ensuring continuous production.

- Led a team to introduce advanced automation technologies that streamlined production processes and enhanced overall plant efficiency.

- Identified and resolved a critical issue in the caustic liquor production system, preventing potential equipment damage and production delays.

- Collaborated with R&D team to evaluate and optimize raw material usage, reducing production costs while maintaining product quality.

Awards

- Received the Caustic Liquor Maker of the Year award for consistently exceeding production targets and maintaining exceptional safety standards.

- Recognized for developing a new quality control procedure that significantly reduced product defects and improved customer satisfaction.

- Honored with the Safety Excellence Award for implementing comprehensive safety measures that effectively reduced workplace accidents.

- Received recognition for mentorship and training of new Caustic Liquor Makers, contributing to the development of highly skilled professionals in the field.

Certificates

- OSHA Hazardous Waste Operations and Emergency Response (HAZWOPER)

- National Fire Protection Association (NFPA) 70E Electrical Safety

- American Society of Mechanical Engineers (ASME) Boiler and Pressure Vessel Code

- Environmental Protection Agency (EPA) Clean Air Act Compliance

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Caustic Liquor Maker

- Highlight your technical skills and experience in caustic liquor manufacturing, emphasizing your ability to operate and maintain equipment, monitor processes, and troubleshoot issues.

- Showcase your safety consciousness and commitment to compliance by describing your experience in implementing and maintaining safety protocols.

- Quantify your accomplishments whenever possible, using specific metrics to demonstrate your impact on process optimization and productivity.

- Proofread your resume carefully for any errors in grammar, spelling, or formatting.

Essential Experience Highlights for a Strong Caustic Liquor Maker Resume

- Operate and maintain caustic liquor manufacturing equipment, including reactors, pumps, and pipelines

- Monitor and control chemical processes to ensure optimal production and product quality

- Troubleshoot and resolve process issues promptly and efficiently

- Implement and maintain safety protocols to minimize risks and ensure compliance with regulatory standards

- Conduct routine inspections and perform preventive maintenance to ensure equipment reliability

- Supervise and train junior staff, providing technical guidance and support

Frequently Asked Questions (FAQ’s) For Caustic Liquor Maker

What is the role of a Caustic Liquor Maker?

A Caustic Liquor Maker is responsible for operating and maintaining equipment used in the production of caustic liquor, a highly corrosive chemical used in various industrial processes.

What are the key skills required for a Caustic Liquor Maker?

Key skills include knowledge of caustic liquor manufacturing processes, chemical process monitoring and control, industrial equipment operation and maintenance, process optimization techniques, safety compliance, and hazard management.

What are the career prospects for a Caustic Liquor Maker?

With experience and additional training, Caustic Liquor Makers can advance to roles such as Production Supervisor, Process Engineer, or Safety Manager.

What is the work environment like for a Caustic Liquor Maker?

Caustic Liquor Makers typically work in industrial settings, operating and maintaining equipment in chemical plants or manufacturing facilities.

What are the safety precautions that a Caustic Liquor Maker must follow?

Caustic Liquor Makers must adhere to strict safety protocols, including wearing protective clothing and equipment, following proper handling procedures, and being aware of potential hazards.

What is the typical salary range for a Caustic Liquor Maker?

Salary can vary depending on experience, location, and employer, but the average salary range is between $50,000 to $75,000 per year.