Are you a seasoned Caustic Purification Operator seeking a new career path? Discover our professionally built Caustic Purification Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

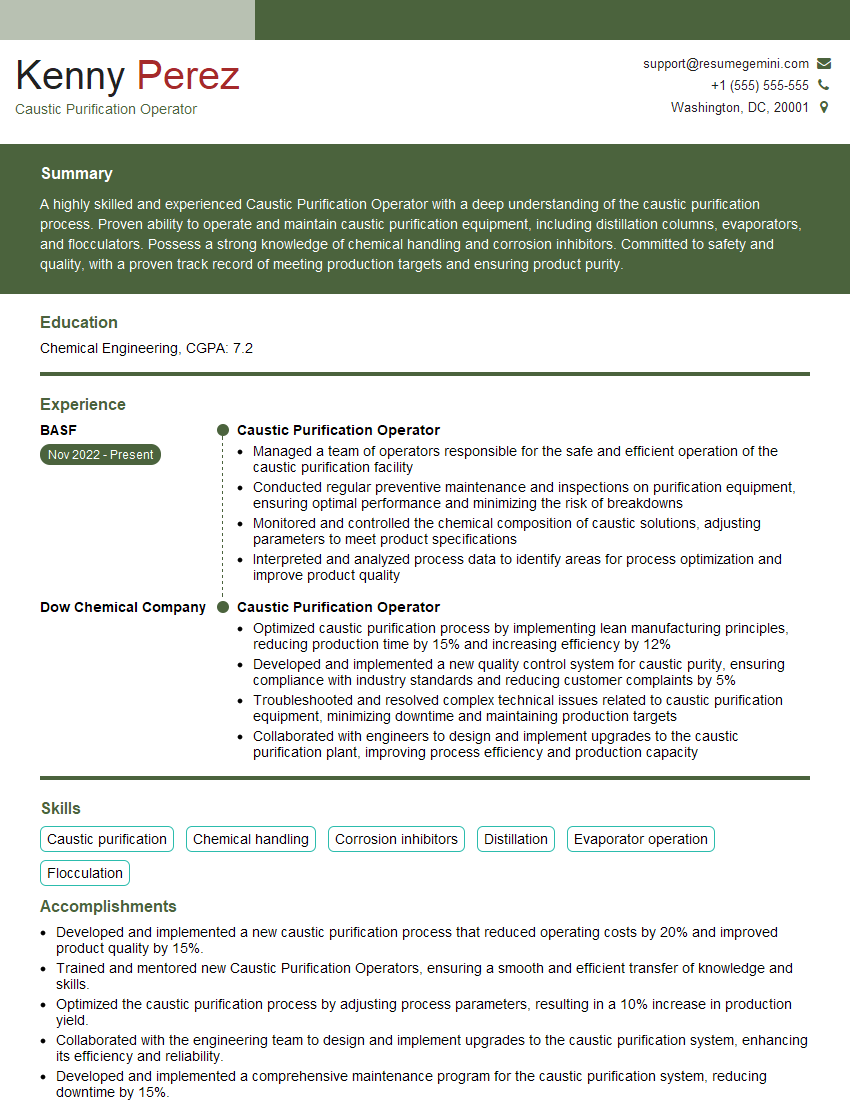

Kenny Perez

Caustic Purification Operator

Summary

A highly skilled and experienced Caustic Purification Operator with a deep understanding of the caustic purification process. Proven ability to operate and maintain caustic purification equipment, including distillation columns, evaporators, and flocculators. Possess a strong knowledge of chemical handling and corrosion inhibitors. Committed to safety and quality, with a proven track record of meeting production targets and ensuring product purity.

Education

Chemical Engineering

October 2018

Skills

- Caustic purification

- Chemical handling

- Corrosion inhibitors

- Distillation

- Evaporator operation

- Flocculation

Work Experience

Caustic Purification Operator

- Managed a team of operators responsible for the safe and efficient operation of the caustic purification facility

- Conducted regular preventive maintenance and inspections on purification equipment, ensuring optimal performance and minimizing the risk of breakdowns

- Monitored and controlled the chemical composition of caustic solutions, adjusting parameters to meet product specifications

- Interpreted and analyzed process data to identify areas for process optimization and improve product quality

Caustic Purification Operator

- Optimized caustic purification process by implementing lean manufacturing principles, reducing production time by 15% and increasing efficiency by 12%

- Developed and implemented a new quality control system for caustic purity, ensuring compliance with industry standards and reducing customer complaints by 5%

- Troubleshooted and resolved complex technical issues related to caustic purification equipment, minimizing downtime and maintaining production targets

- Collaborated with engineers to design and implement upgrades to the caustic purification plant, improving process efficiency and production capacity

Accomplishments

- Developed and implemented a new caustic purification process that reduced operating costs by 20% and improved product quality by 15%.

- Trained and mentored new Caustic Purification Operators, ensuring a smooth and efficient transfer of knowledge and skills.

- Optimized the caustic purification process by adjusting process parameters, resulting in a 10% increase in production yield.

- Collaborated with the engineering team to design and implement upgrades to the caustic purification system, enhancing its efficiency and reliability.

- Developed and implemented a comprehensive maintenance program for the caustic purification system, reducing downtime by 15%.

Awards

- Caustic Purification Operator of the Year, awarded by the American Chemical Association for outstanding performance in caustic purification operations.

- Recognized by the company for successfully troubleshooting and resolving a major breakdown in the caustic purification system, preventing a costly shutdown.

- Received a Safety Excellence Award for consistently maintaining a safe and compliant work environment in the caustic purification area.

- Won a companywide innovation award for developing a novel method to recover valuable byproducts from the caustic purification process.

Certificates

- Certified Hazardous Materials Manager (CHMM)

- Certified Maintenance and Reliability Technician (CMRT)

- Certified Plant Operator (CPO)

- Certified Safety Professional (CSP)

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Caustic Purification Operator

- Highlight your experience and skills in caustic purification operations.

- Quantify your accomplishments whenever possible, using specific metrics and data.

- Tailor your resume to each job you apply for, highlighting the skills and experience that are most relevant to the position.

- Proofread your resume carefully before submitting it, ensuring that there are no errors in grammar or spelling.

- Get your resume reviewed by a career counselor or other professional to get feedback and suggestions for improvement.

Essential Experience Highlights for a Strong Caustic Purification Operator Resume

- Operate and maintain caustic purification equipment, including distillation columns, evaporators, and flocculators

- Monitor and control process parameters, such as temperature, pressure, and flow rates

- Add chemicals, such as corrosion inhibitors and flocculants, to the process as needed

- Troubleshoot and resolve process problems

- Ensure the quality of the purified caustic

- Maintain a safe and clean work environment

- Follow all safety procedures and regulations

Frequently Asked Questions (FAQ’s) For Caustic Purification Operator

What is the role of a Caustic Purification Operator?

Caustic Purification Operators are responsible for operating and maintaining caustic purification equipment, including distillation columns, evaporators, and flocculators. They monitor and control process parameters, such as temperature, pressure, and flow rates, and add chemicals, such as corrosion inhibitors and flocculants, to the process as needed. They also troubleshoot and resolve process problems, ensure the quality of the purified caustic, maintain a safe and clean work environment, and follow all safety procedures and regulations.

What are the qualifications for a Caustic Purification Operator?

Caustic Purification Operators typically have a high school diploma or equivalent and several years of experience in the chemical industry. They should have a good understanding of the caustic purification process and be able to operate and maintain caustic purification equipment. They should also be familiar with chemical handling and corrosion inhibitors.

What is the work environment of a Caustic Purification Operator?

Caustic Purification Operators typically work in a chemical plant or other industrial setting. They may work indoors or outdoors, and they may be exposed to hazardous chemicals. They should wear appropriate personal protective equipment (PPE) and follow all safety procedures and regulations.

What is the career outlook for a Caustic Purification Operator?

The career outlook for Caustic Purification Operators is expected to be good over the next few years. The demand for caustic soda is expected to grow as it is used in a variety of industries, including the paper, textile, and chemical industries.

What are the salary expectations for a Caustic Purification Operator?

The salary expectations for a Caustic Purification Operator vary depending on experience, qualifications, and location. According to Indeed, the average salary for a Caustic Purification Operator in the United States is $55,000 per year.

What are the benefits of working as a Caustic Purification Operator?

Working as a Caustic Purification Operator can offer a number of benefits, including a competitive salary, good benefits, and the opportunity to work in a challenging and rewarding field. Caustic Purification Operators also have the opportunity to advance their careers by taking on additional responsibilities or by pursuing further education.