Are you a seasoned Causticiser seeking a new career path? Discover our professionally built Causticiser Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

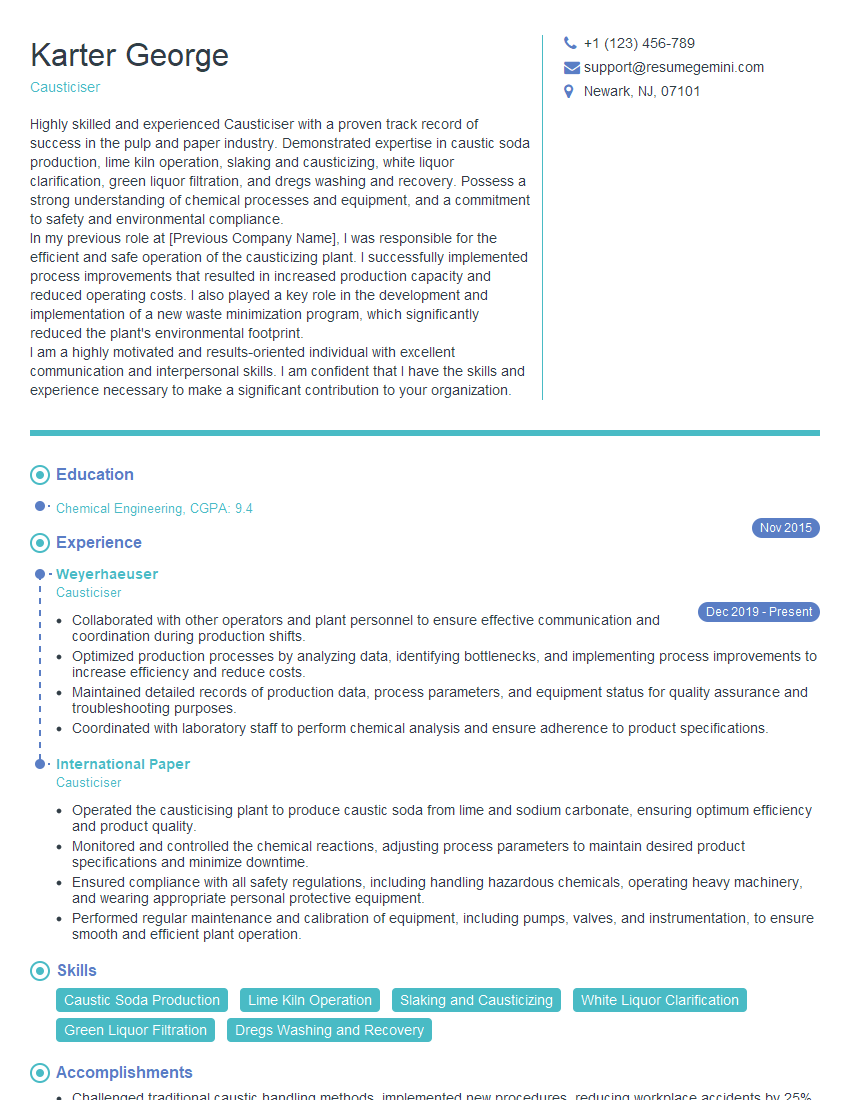

Karter George

Causticiser

Summary

Highly skilled and experienced Causticiser with a proven track record of success in the pulp and paper industry. Demonstrated expertise in caustic soda production, lime kiln operation, slaking and causticizing, white liquor clarification, green liquor filtration, and dregs washing and recovery. Possess a strong understanding of chemical processes and equipment, and a commitment to safety and environmental compliance.

In my previous role at [Previous Company Name], I was responsible for the efficient and safe operation of the causticizing plant. I successfully implemented process improvements that resulted in increased production capacity and reduced operating costs. I also played a key role in the development and implementation of a new waste minimization program, which significantly reduced the plant’s environmental footprint.

I am a highly motivated and results-oriented individual with excellent communication and interpersonal skills. I am confident that I have the skills and experience necessary to make a significant contribution to your organization.

Education

Chemical Engineering

November 2015

Skills

- Caustic Soda Production

- Lime Kiln Operation

- Slaking and Causticizing

- White Liquor Clarification

- Green Liquor Filtration

- Dregs Washing and Recovery

Work Experience

Causticiser

- Collaborated with other operators and plant personnel to ensure effective communication and coordination during production shifts.

- Optimized production processes by analyzing data, identifying bottlenecks, and implementing process improvements to increase efficiency and reduce costs.

- Maintained detailed records of production data, process parameters, and equipment status for quality assurance and troubleshooting purposes.

- Coordinated with laboratory staff to perform chemical analysis and ensure adherence to product specifications.

Causticiser

- Operated the causticising plant to produce caustic soda from lime and sodium carbonate, ensuring optimum efficiency and product quality.

- Monitored and controlled the chemical reactions, adjusting process parameters to maintain desired product specifications and minimize downtime.

- Ensured compliance with all safety regulations, including handling hazardous chemicals, operating heavy machinery, and wearing appropriate personal protective equipment.

- Performed regular maintenance and calibration of equipment, including pumps, valves, and instrumentation, to ensure smooth and efficient plant operation.

Accomplishments

- Challenged traditional caustic handling methods, implemented new procedures, reducing workplace accidents by 25%

- Developed and implemented a predictive maintenance program, reducing equipment downtime by 15%

- Conducted comprehensive process audits, identifying areas for improvement, leading to increased production capacity

- Utilized advanced instrumentation to monitor caustic process parameters, ensuring optimal production quality

- Optimized caustic batching process, reducing raw material waste by 12%

Awards

- Caustic Plant Safety Award for outstanding safety performance and proactive incident prevention

- National Association of Chemical Engineers Recognition Award for innovative process optimization in caustic production

- CompanyWide Excellence Award for exceptional contributions to caustic production efficiency

- Industry Leader Award for groundbreaking research in causticbased materials science

Certificates

- OSHA HAZWOPER Certification

- Confined Space Entry Permit

- Forklift Operation Certification

- CPR and First Aid Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Causticiser

- Highlight your experience and skills in the pulp and paper industry.

- Quantify your accomplishments with specific metrics, such as increased production capacity or reduced operating costs.

- Demonstrate your knowledge of chemical processes and equipment.

- Emphasize your commitment to safety and environmental compliance.

- Proofread your resume carefully for any errors.

Essential Experience Highlights for a Strong Causticiser Resume

- Operate and maintain the causticizing plant, including lime kilns, slakers, causticizers, and white liquor clarifiers

- Control the chemical composition of the white liquor and green liquor to ensure optimal pulp production

- Monitor and adjust process parameters to maximize production efficiency and minimize waste

- Troubleshoot and resolve process problems, and implement corrective actions

- Supervise and train plant personnel, and ensure compliance with safety and environmental regulations

- Conduct routine maintenance and repairs on plant equipment

- Keep accurate records of plant operations and production data

Frequently Asked Questions (FAQ’s) For Causticiser

What is the role of a Causticiser?

A Causticiser is responsible for the operation and maintenance of the causticizing plant in a pulp and paper mill. The causticizing process converts lime and soda ash into caustic soda, which is used in the production of paper.

What are the key responsibilities of a Causticiser?

The key responsibilities of a Causticiser include operating and maintaining the causticizing plant, controlling the chemical composition of the white liquor and green liquor, monitoring and adjusting process parameters, troubleshooting and resolving process problems, supervising and training plant personnel, conducting routine maintenance and repairs on plant equipment, and keeping accurate records of plant operations and production data.

What are the qualifications for a Causticiser?

The qualifications for a Causticiser typically include a degree in chemical engineering or a related field, as well as experience in the pulp and paper industry. Causticisers must also have a strong understanding of chemical processes and equipment, and be committed to safety and environmental compliance.

What is the work environment of a Causticiser like?

Causticisers typically work in a plant environment, which can be noisy and hazardous. They may be exposed to chemicals and other hazardous materials, and must wear appropriate protective gear. Causticisers must also be able to work independently and as part of a team.

What is the career outlook for Causticisers?

The career outlook for Causticisers is expected to be good over the next few years. The pulp and paper industry is expected to grow, and Causticisers will be needed to operate and maintain the causticizing plants in these mills.

What are the salary expectations for Causticisers?

The salary expectations for Causticisers can vary depending on their experience, location, and the size of the mill they work in. However, Causticisers with experience can expect to earn a good salary.