Are you a seasoned Cellophane Casting Machine Repairer seeking a new career path? Discover our professionally built Cellophane Casting Machine Repairer Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

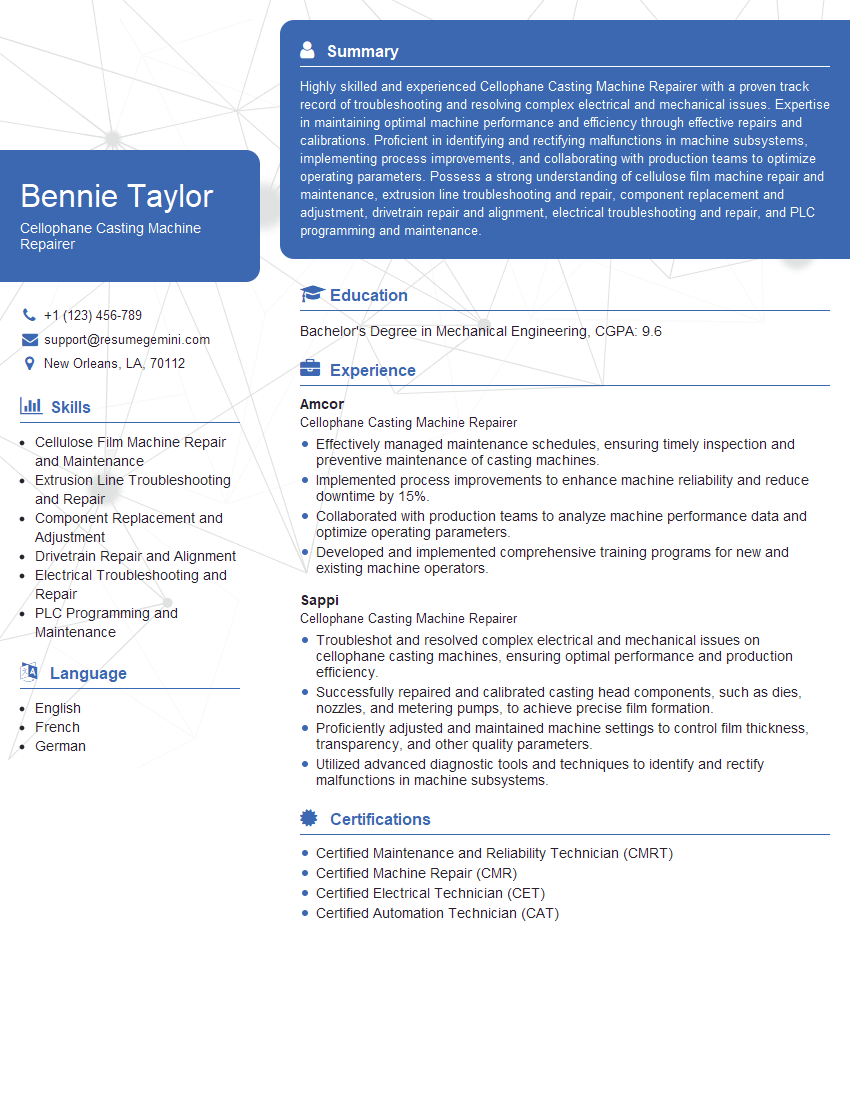

Bennie Taylor

Cellophane Casting Machine Repairer

Summary

Highly skilled and experienced Cellophane Casting Machine Repairer with a proven track record of troubleshooting and resolving complex electrical and mechanical issues. Expertise in maintaining optimal machine performance and efficiency through effective repairs and calibrations. Proficient in identifying and rectifying malfunctions in machine subsystems, implementing process improvements, and collaborating with production teams to optimize operating parameters. Possess a strong understanding of cellulose film machine repair and maintenance, extrusion line troubleshooting and repair, component replacement and adjustment, drivetrain repair and alignment, electrical troubleshooting and repair, and PLC programming and maintenance.

Education

Bachelor’s Degree in Mechanical Engineering

December 2015

Skills

- Cellulose Film Machine Repair and Maintenance

- Extrusion Line Troubleshooting and Repair

- Component Replacement and Adjustment

- Drivetrain Repair and Alignment

- Electrical Troubleshooting and Repair

- PLC Programming and Maintenance

Work Experience

Cellophane Casting Machine Repairer

- Effectively managed maintenance schedules, ensuring timely inspection and preventive maintenance of casting machines.

- Implemented process improvements to enhance machine reliability and reduce downtime by 15%.

- Collaborated with production teams to analyze machine performance data and optimize operating parameters.

- Developed and implemented comprehensive training programs for new and existing machine operators.

Cellophane Casting Machine Repairer

- Troubleshot and resolved complex electrical and mechanical issues on cellophane casting machines, ensuring optimal performance and production efficiency.

- Successfully repaired and calibrated casting head components, such as dies, nozzles, and metering pumps, to achieve precise film formation.

- Proficiently adjusted and maintained machine settings to control film thickness, transparency, and other quality parameters.

- Utilized advanced diagnostic tools and techniques to identify and rectify malfunctions in machine subsystems.

Certificates

- Certified Maintenance and Reliability Technician (CMRT)

- Certified Machine Repair (CMR)

- Certified Electrical Technician (CET)

- Certified Automation Technician (CAT)

Languages

- English

- French

- German

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Cellophane Casting Machine Repairer

Highlight your technical skills:

Emphasize your expertise in electrical and mechanical repair, troubleshooting, and calibration techniques.Showcase your problem-solving abilities:

Describe specific instances where you successfully diagnosed and resolved complex issues on cellophane casting machines.Quantify your accomplishments:

Use numbers and metrics to demonstrate the impact of your work, such as reduced downtime or improved production efficiency.Tailor your resume to the job description:

Carefully review the job description and highlight the skills and experiences that are most relevant to the role.

Essential Experience Highlights for a Strong Cellophane Casting Machine Repairer Resume

- Troubleshoot and resolve complex electrical and mechanical issues on cellophane casting machines to ensure optimal performance and production efficiency.

- Repair and calibrate casting head components, such as dies, nozzles, and metering pumps, to achieve precise film formation.

- Adjust and maintain machine settings to control film thickness, transparency, and other quality parameters.

- Utilize advanced diagnostic tools and techniques to identify and rectify malfunctions in machine subsystems.

- Manage maintenance schedules, ensuring timely inspection and preventive maintenance of casting machines to minimize downtime.

- Collaborate with production teams to analyze machine performance data and optimize operating parameters.

- Develop and implement comprehensive training programs for new and existing machine operators.

Frequently Asked Questions (FAQ’s) For Cellophane Casting Machine Repairer

What are the key responsibilities of a Cellophane Casting Machine Repairer?

Cellophane Casting Machine Repairers are responsible for maintaining, troubleshooting, and repairing cellophane casting machines to ensure optimal performance and production efficiency. Key responsibilities include diagnosing and resolving electrical and mechanical issues, calibrating machine components, adjusting machine settings, and implementing preventive maintenance schedules.

What skills are required to be a successful Cellophane Casting Machine Repairer?

Successful Cellophane Casting Machine Repairers possess a strong understanding of electrical and mechanical systems, as well as expertise in troubleshooting, repair, and calibration techniques. They are also proficient in using diagnostic tools, analyzing machine performance data, and implementing process improvements.

What is the career outlook for Cellophane Casting Machine Repairers?

The career outlook for Cellophane Casting Machine Repairers is expected to be stable in the coming years. The demand for skilled technicians who can maintain and repair complex machinery is increasing, particularly in industries that rely on cellophane production.

What are the educational requirements to become a Cellophane Casting Machine Repairer?

While there are no specific educational requirements to become a Cellophane Casting Machine Repairer, many employers prefer candidates with a high school diploma or equivalent, as well as relevant work experience or technical training in electrical or mechanical fields.

What is the average salary for a Cellophane Casting Machine Repairer?

The average salary for a Cellophane Casting Machine Repairer varies depending on factors such as experience, location, and employer. According to Salary.com, the median annual salary for Cellophane Casting Machine Repairers in the United States is around $65,000.

What are the benefits of working as a Cellophane Casting Machine Repairer?

Cellophane Casting Machine Repairers enjoy several benefits, including job stability, competitive salaries, and opportunities for career advancement. They also have the satisfaction of working in a hands-on environment and contributing to the production of high-quality products.

How can I prepare for a career as a Cellophane Casting Machine Repairer?

To prepare for a career as a Cellophane Casting Machine Repairer, you can gain hands-on experience working with electrical and mechanical systems, pursue technical training or certification programs, and network with professionals in the field. Additionally, developing strong problem-solving and analytical skills is essential.

What are the challenges of working as a Cellophane Casting Machine Repairer?

Cellophane Casting Machine Repairers may face challenges such as working in demanding environments, dealing with complex technical issues, and meeting tight production deadlines. They may also need to work overtime or on weekends to ensure the smooth operation of production lines.