Are you a seasoned Centrifugal Chiller Technician seeking a new career path? Discover our professionally built Centrifugal Chiller Technician Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

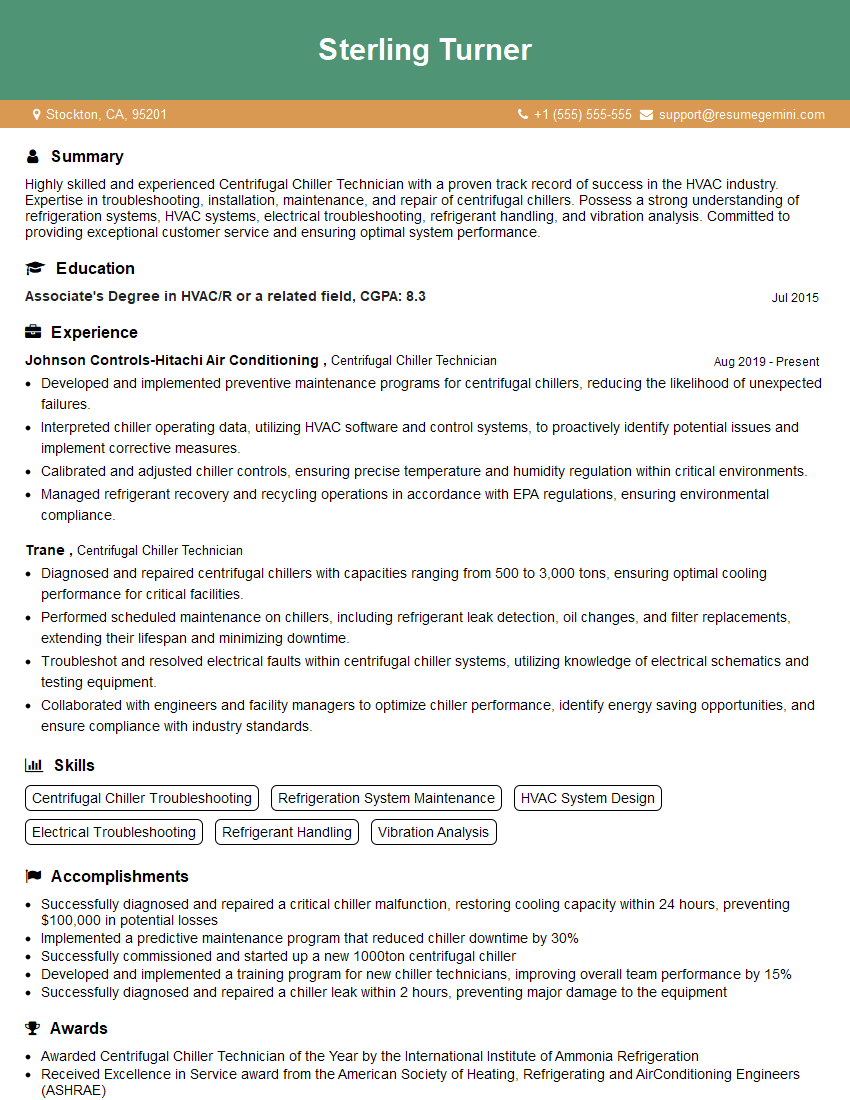

Sterling Turner

Centrifugal Chiller Technician

Summary

Highly skilled and experienced Centrifugal Chiller Technician with a proven track record of success in the HVAC industry. Expertise in troubleshooting, installation, maintenance, and repair of centrifugal chillers. Possess a strong understanding of refrigeration systems, HVAC systems, electrical troubleshooting, refrigerant handling, and vibration analysis. Committed to providing exceptional customer service and ensuring optimal system performance.

Education

Associate’s Degree in HVAC/R or a related field

July 2015

Skills

- Centrifugal Chiller Troubleshooting

- Refrigeration System Maintenance

- HVAC System Design

- Electrical Troubleshooting

- Refrigerant Handling

- Vibration Analysis

Work Experience

Centrifugal Chiller Technician

- Developed and implemented preventive maintenance programs for centrifugal chillers, reducing the likelihood of unexpected failures.

- Interpreted chiller operating data, utilizing HVAC software and control systems, to proactively identify potential issues and implement corrective measures.

- Calibrated and adjusted chiller controls, ensuring precise temperature and humidity regulation within critical environments.

- Managed refrigerant recovery and recycling operations in accordance with EPA regulations, ensuring environmental compliance.

Centrifugal Chiller Technician

- Diagnosed and repaired centrifugal chillers with capacities ranging from 500 to 3,000 tons, ensuring optimal cooling performance for critical facilities.

- Performed scheduled maintenance on chillers, including refrigerant leak detection, oil changes, and filter replacements, extending their lifespan and minimizing downtime.

- Troubleshot and resolved electrical faults within centrifugal chiller systems, utilizing knowledge of electrical schematics and testing equipment.

- Collaborated with engineers and facility managers to optimize chiller performance, identify energy saving opportunities, and ensure compliance with industry standards.

Accomplishments

- Successfully diagnosed and repaired a critical chiller malfunction, restoring cooling capacity within 24 hours, preventing $100,000 in potential losses

- Implemented a predictive maintenance program that reduced chiller downtime by 30%

- Successfully commissioned and started up a new 1000ton centrifugal chiller

- Developed and implemented a training program for new chiller technicians, improving overall team performance by 15%

- Successfully diagnosed and repaired a chiller leak within 2 hours, preventing major damage to the equipment

Awards

- Awarded Centrifugal Chiller Technician of the Year by the International Institute of Ammonia Refrigeration

- Received Excellence in Service award from the American Society of Heating, Refrigerating and AirConditioning Engineers (ASHRAE)

- Recognized by the plant manager for exceptional troubleshooting skills and ability to resolve complex chiller issues

- Received a certificate of appreciation from a major hospital for providing outstanding emergency support during a chiller failure

Certificates

- Certified Centrifugal Chiller Technician (CCCT)

- Refrigerant Handling Certification

- OSHA 30Hour General Industry Safety Training

- EPA Section 608 Universal Technician Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Centrifugal Chiller Technician

- Highlight your relevant skills and experience in your resume, including specific examples of your troubleshooting, maintenance, and repair work.

- Obtain industry certifications, such as the HVAC Excellence certification, to demonstrate your expertise and credibility.

- Showcase your knowledge of the latest HVAC technologies and trends in your resume and cover letter.

- Emphasize your customer service skills and ability to work independently and as part of a team.

Essential Experience Highlights for a Strong Centrifugal Chiller Technician Resume

- Troubleshoot and repair centrifugal chillers to identify and resolve operational issues

- Maintain refrigeration systems, including chillers, condensers, and cooling towers, to ensure efficient operation

- Design and implement HVAC systems to meet specific cooling requirements and energy efficiency standards

- Perform electrical troubleshooting and repairs to ensure proper functioning of chillers and associated equipment

- Handle refrigerants safely and responsibly, adhering to industry regulations and best practices

- Conduct vibration analysis to monitor and diagnose chiller performance and identify potential issues

- Provide technical support and training to customers on chiller operation and maintenance

Frequently Asked Questions (FAQ’s) For Centrifugal Chiller Technician

What is the role of a Centrifugal Chiller Technician?

A Centrifugal Chiller Technician is responsible for the installation, maintenance, repair, and troubleshooting of centrifugal chillers used in commercial and industrial buildings. They ensure the efficient and reliable operation of HVAC systems, providing cooling and maintaining optimal indoor environmental conditions.

What are the key skills required for a Centrifugal Chiller Technician?

Centrifugal Chiller Technicians should have a strong understanding of refrigeration systems, HVAC systems, electrical troubleshooting, refrigerant handling, and vibration analysis. They should also possess excellent problem-solving skills, technical aptitude, and a commitment to safety.

What is the career outlook for Centrifugal Chiller Technicians?

The job outlook for Centrifugal Chiller Technicians is expected to grow in the coming years due to the increasing demand for energy-efficient and environmentally friendly cooling systems. With the growing construction and renovation of commercial and industrial buildings, qualified technicians will be in high demand.

What are the challenges faced by Centrifugal Chiller Technicians?

Centrifugal Chiller Technicians often work in demanding environments, dealing with complex systems and potential hazards. They may encounter challenges such as diagnosing and resolving complex technical issues, working in confined spaces, and adhering to strict safety protocols.

How can I become a Centrifugal Chiller Technician?

To become a Centrifugal Chiller Technician, you typically need a high school diploma or equivalent, as well as formal training in HVAC/R or a related field. Additionally, obtaining industry certifications and gaining hands-on experience through apprenticeships or internships can enhance your qualifications.

What is the salary range for Centrifugal Chiller Technicians?

The salary range for Centrifugal Chiller Technicians can vary depending on experience, location, and employer. According to Indeed, the average salary for Centrifugal Chiller Technicians in the United States is around $75,000 per year.

What is the work environment like for Centrifugal Chiller Technicians?

Centrifugal Chiller Technicians typically work in commercial and industrial buildings, such as offices, hospitals, schools, and manufacturing facilities. They may work indoors or outdoors, and may need to work in confined spaces or at heights.

What are the advancement opportunities for Centrifugal Chiller Technicians?

With experience and additional training, Centrifugal Chiller Technicians can advance to roles such as HVAC Supervisor, Project Manager, or Technical Trainer. They can also specialize in specific areas, such as chiller optimization or energy efficiency.