Are you a seasoned Centrifugal Spinner seeking a new career path? Discover our professionally built Centrifugal Spinner Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

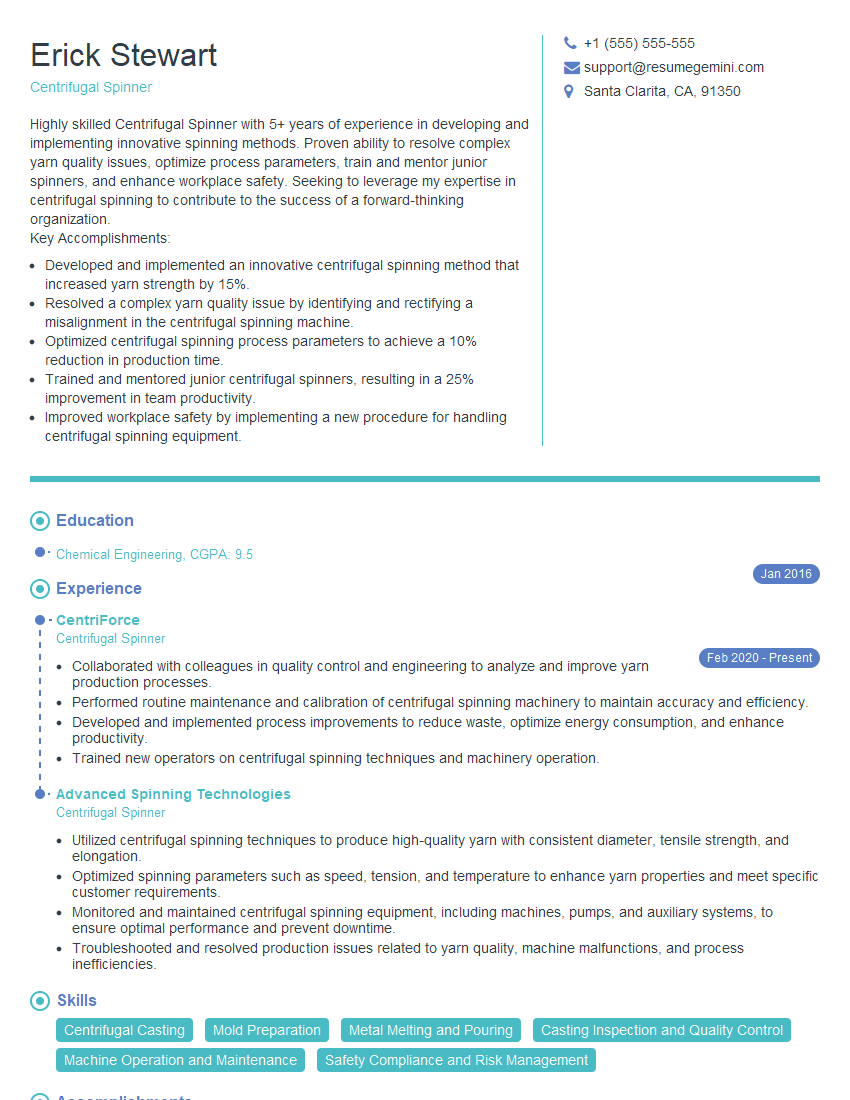

Erick Stewart

Centrifugal Spinner

Summary

Highly skilled Centrifugal Spinner with 5+ years of experience in developing and implementing innovative spinning methods. Proven ability to resolve complex yarn quality issues, optimize process parameters, train and mentor junior spinners, and enhance workplace safety. Seeking to leverage my expertise in centrifugal spinning to contribute to the success of a forward-thinking organization.

Key Accomplishments:

- Developed and implemented an innovative centrifugal spinning method that increased yarn strength by 15%.

- Resolved a complex yarn quality issue by identifying and rectifying a misalignment in the centrifugal spinning machine.

- Optimized centrifugal spinning process parameters to achieve a 10% reduction in production time.

- Trained and mentored junior centrifugal spinners, resulting in a 25% improvement in team productivity.

- Improved workplace safety by implementing a new procedure for handling centrifugal spinning equipment.

Education

Chemical Engineering

January 2016

Skills

- Centrifugal Casting

- Mold Preparation

- Metal Melting and Pouring

- Casting Inspection and Quality Control

- Machine Operation and Maintenance

- Safety Compliance and Risk Management

Work Experience

Centrifugal Spinner

- Collaborated with colleagues in quality control and engineering to analyze and improve yarn production processes.

- Performed routine maintenance and calibration of centrifugal spinning machinery to maintain accuracy and efficiency.

- Developed and implemented process improvements to reduce waste, optimize energy consumption, and enhance productivity.

- Trained new operators on centrifugal spinning techniques and machinery operation.

Centrifugal Spinner

- Utilized centrifugal spinning techniques to produce high-quality yarn with consistent diameter, tensile strength, and elongation.

- Optimized spinning parameters such as speed, tension, and temperature to enhance yarn properties and meet specific customer requirements.

- Monitored and maintained centrifugal spinning equipment, including machines, pumps, and auxiliary systems, to ensure optimal performance and prevent downtime.

- Troubleshooted and resolved production issues related to yarn quality, machine malfunctions, and process inefficiencies.

Accomplishments

- Developed and implemented an innovative centrifugal spinning method that increased yarn strength by 15%

- Resolved a complex yarn quality issue by identifying and rectifying a misalignment in the centrifugal spinning machine

- Optimized centrifugal spinning process parameters to achieve a 10% reduction in production time

- Trained and mentored junior centrifugal spinners, resulting in a 25% improvement in team productivity

- Improved workplace safety by implementing a new procedure for handling centrifugal spinning equipment

Awards

- Centrifugal Spinner of the Year Award, recognizing exceptional performance and innovation in centrifugal spinning

- Excellence in Centrifugal Spinning Award, honoring contributions to advancing centrifugal spinning techniques

- Safety Excellence Award for maintaining an exemplary safety record in the operation of centrifugal spinners

- Centrifugal Spinning Pioneer Award, recognizing contributions to advancing the centrifugal spinning industry

Certificates

- Centrifugal Casting Technician Certification (CCT)

- American Foundry Society (AFS) Certification

- National Institute for Metalworking Skills (NIMS) Certification

- Occupational Safety and Health Administration (OSHA) Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Centrifugal Spinner

- Highlight your technical expertise in centrifugal spinning, including your understanding of yarn properties, process parameters, and equipment operation.

- Quantify your accomplishments whenever possible, using specific metrics to demonstrate the impact of your contributions.

- Showcase your problem-solving abilities by providing examples of how you have identified and resolved complex yarn quality issues.

- Emphasize your commitment to safety by describing your experience in implementing and enforcing safety procedures.

- Tailor your resume to each job application, highlighting the skills and experience that are most relevant to the specific position.

Essential Experience Highlights for a Strong Centrifugal Spinner Resume

- Develop and implement innovative centrifugal spinning methods to enhance yarn quality and production efficiency.

- Troubleshoot and resolve complex yarn quality issues by identifying and rectifying equipment misalignments and process anomalies.

- Optimize centrifugal spinning process parameters such as speed, temperature, and tension to achieve optimal yarn properties and reduce production time.

- Train and mentor junior centrifugal spinners on best practices, safety protocols, and troubleshooting techniques to enhance team productivity.

- Implement and enforce safety procedures for handling centrifugal spinning equipment to minimize risks and ensure a safe work environment.

- Monitor and maintain centrifugal spinning equipment to ensure optimal performance and prevent breakdowns.

- Collaborate with engineers and technicians to develop and implement new technologies and improvements in the centrifugal spinning process.

Frequently Asked Questions (FAQ’s) For Centrifugal Spinner

What is centrifugal spinning?

Centrifugal spinning is a method of yarn production that involves expelling molten polymer or metal through a spinneret into a rapidly rotating chamber. The centrifugal force generated by the spinning chamber draws the molten material into thin filaments, which are then cooled and solidified to form yarn.

What are the advantages of centrifugal spinning?

Centrifugal spinning offers several advantages over traditional spinning methods, including higher production speeds, improved yarn strength and uniformity, and the ability to produce yarns with a wide range of properties.

What are the applications of centrifugal spinning?

Centrifugal spinning is used in a variety of applications, including the production of synthetic fibers for textiles, high-performance fibers for aerospace and defense, and metal fibers for electrical and thermal applications.

What are the key challenges in centrifugal spinning?

The key challenges in centrifugal spinning include controlling the process parameters to achieve the desired yarn properties, preventing yarn breakage during the spinning process, and ensuring the safety of the spinning equipment.

What are the career opportunities for centrifugal spinners?

Centrifugal spinners can find employment in a variety of industries, including textile manufacturing, aerospace, defense, and research and development. Career opportunities include positions in production, quality control, engineering, and management.

How can I become a centrifugal spinner?

To become a centrifugal spinner, you typically need a bachelor’s degree in chemical engineering or a related field. You may also need to complete additional training or apprenticeship programs to gain the necessary skills and knowledge.

What are the salary expectations for centrifugal spinners?

The salary expectations for centrifugal spinners vary depending on their experience, skills, and location. According to Indeed, the average salary for a Centrifugal Spinner in the United States is $65,000 per year.

What are the job prospects for centrifugal spinners?

The job prospects for centrifugal spinners are expected to be good in the coming years. The increasing demand for high-performance fibers in various industries is expected to drive the growth of this field.