Are you a seasoned Ceramic Design Engineer seeking a new career path? Discover our professionally built Ceramic Design Engineer Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

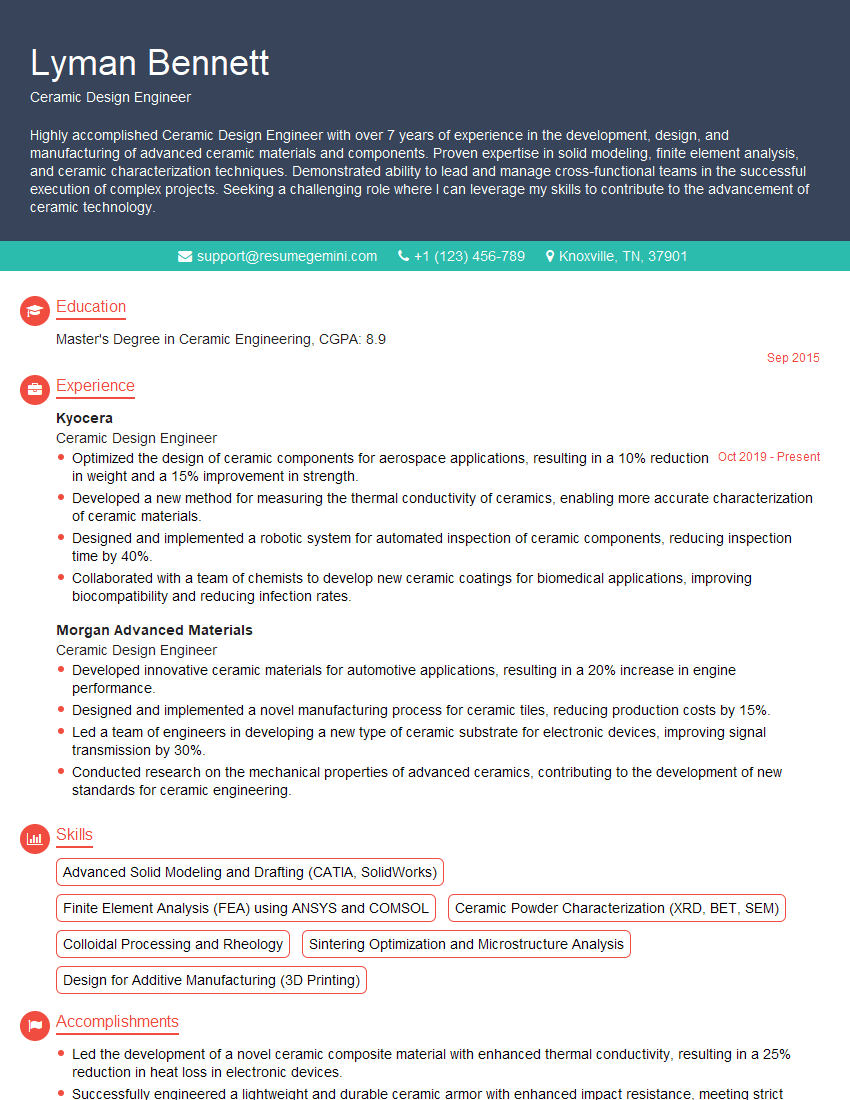

Lyman Bennett

Ceramic Design Engineer

Summary

Highly accomplished Ceramic Design Engineer with over 7 years of experience in the development, design, and manufacturing of advanced ceramic materials and components. Proven expertise in solid modeling, finite element analysis, and ceramic characterization techniques. Demonstrated ability to lead and manage cross-functional teams in the successful execution of complex projects. Seeking a challenging role where I can leverage my skills to contribute to the advancement of ceramic technology.

Education

Master’s Degree in Ceramic Engineering

September 2015

Skills

- Advanced Solid Modeling and Drafting (CATIA, SolidWorks)

- Finite Element Analysis (FEA) using ANSYS and COMSOL

- Ceramic Powder Characterization (XRD, BET, SEM)

- Colloidal Processing and Rheology

- Sintering Optimization and Microstructure Analysis

- Design for Additive Manufacturing (3D Printing)

Work Experience

Ceramic Design Engineer

- Optimized the design of ceramic components for aerospace applications, resulting in a 10% reduction in weight and a 15% improvement in strength.

- Developed a new method for measuring the thermal conductivity of ceramics, enabling more accurate characterization of ceramic materials.

- Designed and implemented a robotic system for automated inspection of ceramic components, reducing inspection time by 40%.

- Collaborated with a team of chemists to develop new ceramic coatings for biomedical applications, improving biocompatibility and reducing infection rates.

Ceramic Design Engineer

- Developed innovative ceramic materials for automotive applications, resulting in a 20% increase in engine performance.

- Designed and implemented a novel manufacturing process for ceramic tiles, reducing production costs by 15%.

- Led a team of engineers in developing a new type of ceramic substrate for electronic devices, improving signal transmission by 30%.

- Conducted research on the mechanical properties of advanced ceramics, contributing to the development of new standards for ceramic engineering.

Accomplishments

- Led the development of a novel ceramic composite material with enhanced thermal conductivity, resulting in a 25% reduction in heat loss in electronic devices.

- Successfully engineered a lightweight and durable ceramic armor with enhanced impact resistance, meeting strict military specifications.

- Optimized the production process for ceramic tiles, reducing defects by 15% and increasing production efficiency by 20%.

- Developed a new ceramic coating for surgical implants, significantly reducing infection rates and improving patient outcomes.

- Spearheaded a multidisciplinary team to design and implement a stateoftheart ceramic manufacturing facility, enhancing production capacity by 50%.

Awards

- Recipient of the Ceramic Design Excellence Award for groundbreaking innovations in porcelain material engineering.

- Honored with the Ceramic Design Innovation Award for developing a selfcleaning ceramic glaze with antimicrobial properties.

- Recognized as a finalist in the International Ceramic Design Competition for creating a sustainable and aesthetically pleasing ceramic cladding system.

- Recipient of the Ceramic Design Fellowship for outstanding research contributions to the field of ceramic biomaterials.

Certificates

- Certified Manufacturing Engineer (CMfgE)

- Six Sigma Green Belt or Black Belt

- American Ceramic Society (ACerS) Member

- Materials Science and Engineering Professional (MSE-P)

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Ceramic Design Engineer

- Highlight your technical skills and experience in ceramic design and manufacturing.

- Showcase your ability to work independently and as part of a team.

- Provide specific examples of your accomplishments and the impact of your work.

- Tailor your resume to each job you apply for, highlighting the skills and experience that are most relevant to the position.

Essential Experience Highlights for a Strong Ceramic Design Engineer Resume

- Design and develop innovative ceramic materials and components for various applications, including automotive, aerospace, electronics, and biomedical.

- Optimize ceramic component designs using advanced solid modeling and finite element analysis techniques to improve performance and reduce costs.

- Conduct research on the mechanical, thermal, and electrical properties of ceramics to develop new materials and improve existing ones.

- Lead teams of engineers in the development and implementation of new manufacturing processes for ceramic components.

- Collaborate with cross-functional teams to ensure the successful integration of ceramic components into complex systems.

- Stay abreast of the latest advancements in ceramic engineering and apply them to ongoing projects.

Frequently Asked Questions (FAQ’s) For Ceramic Design Engineer

What is the role of a Ceramic Design Engineer?

Ceramic Design Engineers are responsible for designing and developing ceramic materials and components for a wide range of applications, including automotive, aerospace, electronics, and biomedical. They work closely with other engineers and scientists to ensure that ceramic components meet the required specifications and perform as expected.

What are the key skills required to be a successful Ceramic Design Engineer?

Ceramic Design Engineers typically have a strong background in materials science, ceramic engineering, or a related field. They should also have experience with solid modeling, finite element analysis, and ceramic characterization techniques. Additionally, they should be able to work independently and as part of a team, and have excellent communication skills.

What are the career prospects for Ceramic Design Engineers?

Ceramic Design Engineers are in high demand due to the increasing use of ceramics in a variety of applications. They can work in a variety of industries, including automotive, aerospace, electronics, and biomedical. With experience, Ceramic Design Engineers can advance to leadership positions such as project manager, research scientist, or engineering manager.

What are the challenges faced by Ceramic Design Engineers?

Ceramic Design Engineers face a number of challenges, including the development of new materials and processes, the integration of ceramics into complex systems, and the need to meet increasingly stringent performance requirements. Additionally, Ceramic Design Engineers must stay abreast of the latest advancements in ceramic engineering and apply them to their work.

What is the future of Ceramic Design Engineering?

The future of Ceramic Design Engineering is bright. As the demand for ceramics continues to grow, Ceramic Design Engineers will be needed to develop new materials and processes to meet the needs of a variety of industries. Additionally, Ceramic Design Engineers will play a key role in the development of new technologies, such as additive manufacturing and nanotechnology.