Are you a seasoned Chalk Molding Machine Operator seeking a new career path? Discover our professionally built Chalk Molding Machine Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

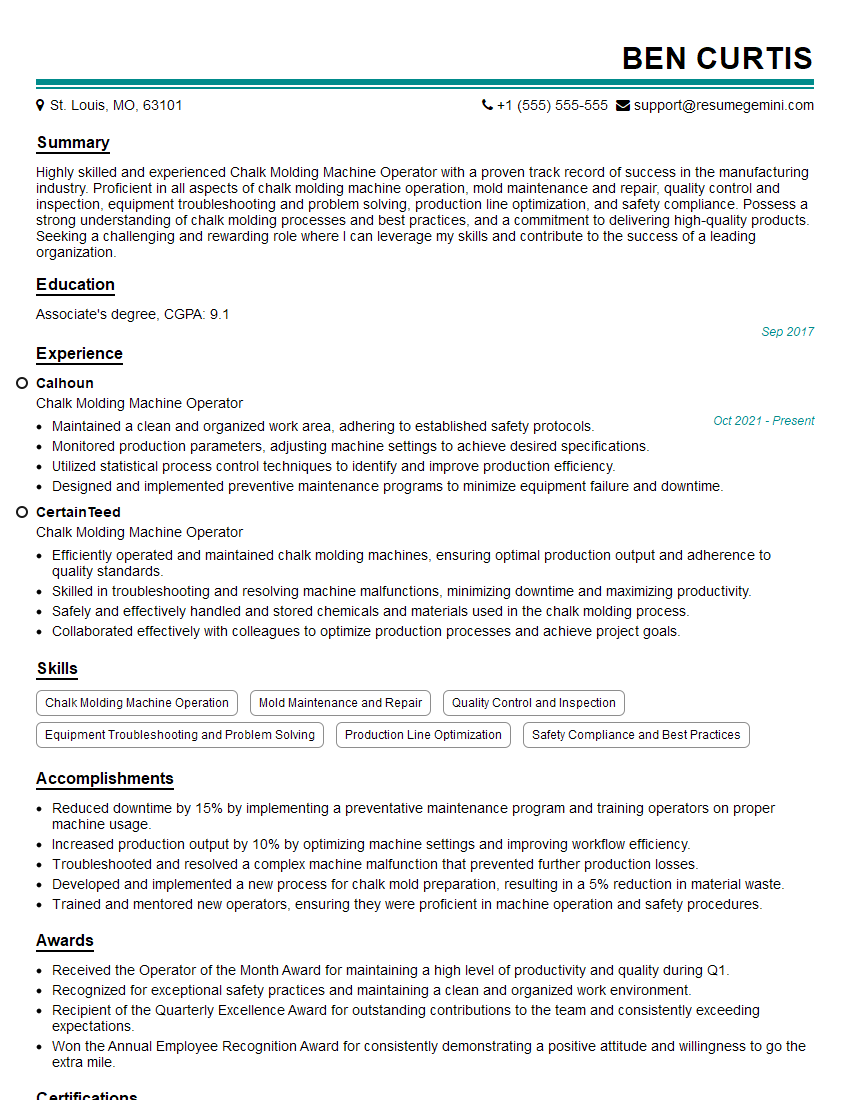

Ben Curtis

Chalk Molding Machine Operator

Summary

Highly skilled and experienced Chalk Molding Machine Operator with a proven track record of success in the manufacturing industry. Proficient in all aspects of chalk molding machine operation, mold maintenance and repair, quality control and inspection, equipment troubleshooting and problem solving, production line optimization, and safety compliance. Possess a strong understanding of chalk molding processes and best practices, and a commitment to delivering high-quality products. Seeking a challenging and rewarding role where I can leverage my skills and contribute to the success of a leading organization.

Education

Associate’s degree

September 2017

Skills

- Chalk Molding Machine Operation

- Mold Maintenance and Repair

- Quality Control and Inspection

- Equipment Troubleshooting and Problem Solving

- Production Line Optimization

- Safety Compliance and Best Practices

Work Experience

Chalk Molding Machine Operator

- Maintained a clean and organized work area, adhering to established safety protocols.

- Monitored production parameters, adjusting machine settings to achieve desired specifications.

- Utilized statistical process control techniques to identify and improve production efficiency.

- Designed and implemented preventive maintenance programs to minimize equipment failure and downtime.

Chalk Molding Machine Operator

- Efficiently operated and maintained chalk molding machines, ensuring optimal production output and adherence to quality standards.

- Skilled in troubleshooting and resolving machine malfunctions, minimizing downtime and maximizing productivity.

- Safely and effectively handled and stored chemicals and materials used in the chalk molding process.

- Collaborated effectively with colleagues to optimize production processes and achieve project goals.

Accomplishments

- Reduced downtime by 15% by implementing a preventative maintenance program and training operators on proper machine usage.

- Increased production output by 10% by optimizing machine settings and improving workflow efficiency.

- Troubleshooted and resolved a complex machine malfunction that prevented further production losses.

- Developed and implemented a new process for chalk mold preparation, resulting in a 5% reduction in material waste.

- Trained and mentored new operators, ensuring they were proficient in machine operation and safety procedures.

Awards

- Received the Operator of the Month Award for maintaining a high level of productivity and quality during Q1.

- Recognized for exceptional safety practices and maintaining a clean and organized work environment.

- Recipient of the Quarterly Excellence Award for outstanding contributions to the team and consistently exceeding expectations.

- Won the Annual Employee Recognition Award for consistently demonstrating a positive attitude and willingness to go the extra mile.

Certificates

- Certified Chalk Molding Machine Operator

- Lean Six Sigma Certification

- OSHA Safety Certification

- PLC Programming Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Chalk Molding Machine Operator

- Highlight your skills and experience in chalk molding machine operation and maintenance.

- Quantify your accomplishments whenever possible to demonstrate the impact of your work.

- Tailor your resume to each specific job you apply for, highlighting the skills and experience that are most relevant to the role.

- Proofread your resume carefully before submitting it to ensure there are no errors.

Essential Experience Highlights for a Strong Chalk Molding Machine Operator Resume

- Operate chalk molding machines to produce high-quality chalk products according to specifications.

- Perform routine maintenance and repairs on chalk molding machines, including cleaning, lubrication, and adjustments.

- Conduct quality control inspections on chalk products to ensure conformance to standards.

- Troubleshoot and resolve equipment malfunctions and problems to minimize downtime.

- Optimize production processes to improve efficiency and productivity.

- Adhere to safety regulations and best practices to ensure a safe work environment.

- Maintain a clean and organized work area.

Frequently Asked Questions (FAQ’s) For Chalk Molding Machine Operator

What are the key skills required to be a successful Chalk Molding Machine Operator?

The key skills required for a successful Chalk Molding Machine Operator include proficiency in chalk molding machine operation, mold maintenance and repair, quality control and inspection, equipment troubleshooting and problem solving, production line optimization, and safety compliance.

What is the typical work environment for a Chalk Molding Machine Operator?

Chalk Molding Machine Operators generally work in manufacturing facilities, operating chalk molding machines to produce chalk products. They may also be responsible for maintaining and repairing equipment, conducting quality inspections, and troubleshooting problems.

What are the career prospects for a Chalk Molding Machine Operator?

Chalk Molding Machine Operators with experience and skills can advance to supervisory roles, quality control positions, or production management positions. They may also specialize in a particular area of chalk molding, such as mold design or equipment maintenance.

What are the challenges faced by a Chalk Molding Machine Operator?

Chalk Molding Machine Operators may face challenges such as working with heavy equipment, exposure to dust and chemicals, and repetitive tasks. They must also be able to work independently and as part of a team, and be able to meet production targets while maintaining quality standards.

What is the salary range for a Chalk Molding Machine Operator?

The salary range for a Chalk Molding Machine Operator can vary depending on experience, skills, and location. According to Salary.com, the average annual salary for a Chalk Molding Machine Operator in the United States is around $45,000.

What are the educational requirements for a Chalk Molding Machine Operator?

While there are no formal educational requirements for Chalk Molding Machine Operators, many employers prefer candidates with a high school diploma or equivalent. Some employers may also require candidates to have experience operating machinery or working in a manufacturing environment.

What are the job duties of a Chalk Molding Machine Operator?

Chalk Molding Machine Operators are responsible for operating chalk molding machines to produce chalk products, maintaining and repairing equipment, conducting quality inspections, and troubleshooting problems. They also optimize production processes, adhere to safety regulations, and maintain a clean and organized work area.

What are the benefits of working as a Chalk Molding Machine Operator?

Chalk Molding Machine Operators can enjoy several benefits, such as job stability, opportunities for advancement, and competitive salaries. They also have the satisfaction of working in a field that helps to create products that are used by people around the world.