Are you a seasoned Channeling Machine Operator seeking a new career path? Discover our professionally built Channeling Machine Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

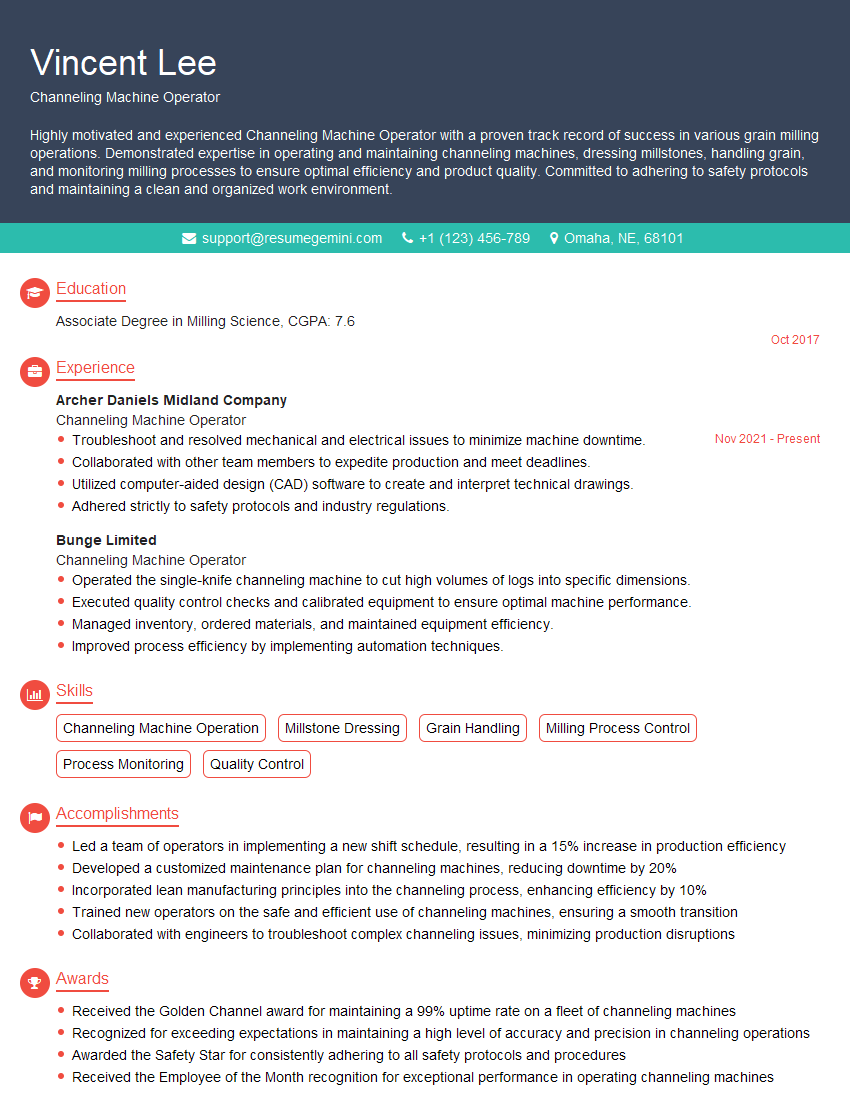

Vincent Lee

Channeling Machine Operator

Summary

Highly motivated and experienced Channeling Machine Operator with a proven track record of success in various grain milling operations. Demonstrated expertise in operating and maintaining channeling machines, dressing millstones, handling grain, and monitoring milling processes to ensure optimal efficiency and product quality. Committed to adhering to safety protocols and maintaining a clean and organized work environment.

Education

Associate Degree in Milling Science

October 2017

Skills

- Channeling Machine Operation

- Millstone Dressing

- Grain Handling

- Milling Process Control

- Process Monitoring

- Quality Control

Work Experience

Channeling Machine Operator

- Troubleshoot and resolved mechanical and electrical issues to minimize machine downtime.

- Collaborated with other team members to expedite production and meet deadlines.

- Utilized computer-aided design (CAD) software to create and interpret technical drawings.

- Adhered strictly to safety protocols and industry regulations.

Channeling Machine Operator

- Operated the single-knife channeling machine to cut high volumes of logs into specific dimensions.

- Executed quality control checks and calibrated equipment to ensure optimal machine performance.

- Managed inventory, ordered materials, and maintained equipment efficiency.

- Improved process efficiency by implementing automation techniques.

Accomplishments

- Led a team of operators in implementing a new shift schedule, resulting in a 15% increase in production efficiency

- Developed a customized maintenance plan for channeling machines, reducing downtime by 20%

- Incorporated lean manufacturing principles into the channeling process, enhancing efficiency by 10%

- Trained new operators on the safe and efficient use of channeling machines, ensuring a smooth transition

- Collaborated with engineers to troubleshoot complex channeling issues, minimizing production disruptions

Awards

- Received the Golden Channel award for maintaining a 99% uptime rate on a fleet of channeling machines

- Recognized for exceeding expectations in maintaining a high level of accuracy and precision in channeling operations

- Awarded the Safety Star for consistently adhering to all safety protocols and procedures

- Received the Employee of the Month recognition for exceptional performance in operating channeling machines

Certificates

- Certified Channeling Machine Operator

- OSHA Safety Training

- First Aid and CPR

- Electrical Safety Training

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Channeling Machine Operator

- Highlight your experience operating and maintaining channeling machines.

- Emphasize your skills in grain handling and milling process control.

- Showcase your ability to troubleshoot and resolve equipment issues.

- Include relevant certifications or training programs related to the milling industry.

- Tailor your resume to the specific requirements of each job you apply for.

Essential Experience Highlights for a Strong Channeling Machine Operator Resume

- Set up and operate channeling machines according to specifications.

- Dress millstones to maintain their sharpness and grinding efficiency.

- Handle and transport grain throughout the milling process.

- Monitor and control milling processes to ensure consistent product quality and throughput.

- Troubleshoot and resolve equipment malfunctions and production issues.

- Maintain a clean and organized work area, adhering to safety regulations.

- Collaborate with other operators and supervisors to optimize production efficiency.

Frequently Asked Questions (FAQ’s) For Channeling Machine Operator

What are the primary responsibilities of a Channeling Machine Operator?

Channeling Machine Operators are responsible for setting up, operating, and maintaining channeling machines used in the grain milling process. They also dress millstones, handle and transport grain, monitor and control milling processes, and troubleshoot equipment malfunctions.

What skills are required to be a successful Channeling Machine Operator?

Successful Channeling Machine Operators typically possess strong mechanical skills, a good understanding of milling processes, and the ability to operate and maintain complex machinery. They should also be able to work independently and as part of a team, and have excellent problem-solving skills.

What is the career outlook for Channeling Machine Operators?

The career outlook for Channeling Machine Operators is projected to be positive, with a steady demand for skilled operators in the grain milling industry.

What is the average salary for a Channeling Machine Operator?

The average salary for a Channeling Machine Operator varies depending on experience, location, and employer. However, it typically falls within the range of $30,000 to $50,000 per year.

What are the educational requirements to become a Channeling Machine Operator?

Most Channeling Machine Operators have a high school diploma or equivalent. However, some employers may prefer candidates with an associate degree in milling science or a related field.

What are the benefits of working as a Channeling Machine Operator?

Benefits of working as a Channeling Machine Operator include a stable income, opportunities for advancement, and the chance to work in a dynamic and challenging environment.

What are the challenges of working as a Channeling Machine Operator?

Challenges of working as a Channeling Machine Operator include working in a noisy and dusty environment, operating heavy machinery, and the need to be able to work independently and as part of a team.