Are you a seasoned Charge Hand seeking a new career path? Discover our professionally built Charge Hand Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

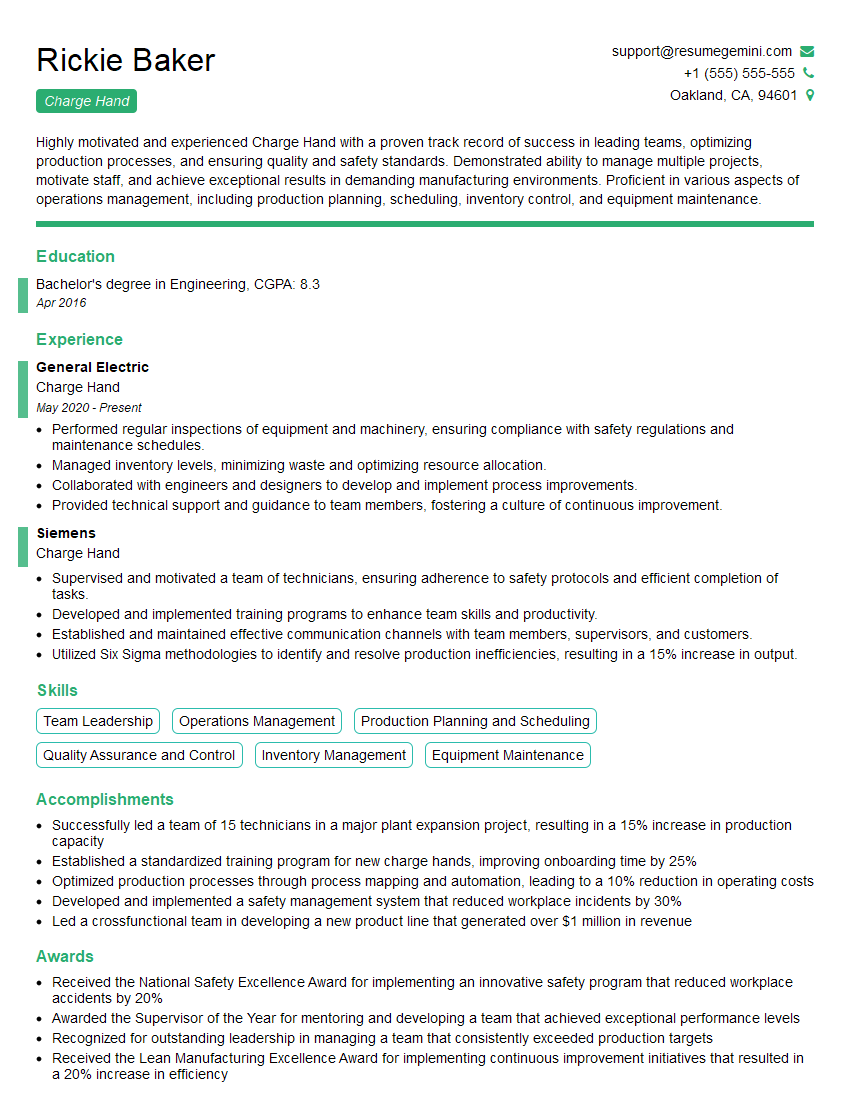

Rickie Baker

Charge Hand

Summary

Highly motivated and experienced Charge Hand with a proven track record of success in leading teams, optimizing production processes, and ensuring quality and safety standards. Demonstrated ability to manage multiple projects, motivate staff, and achieve exceptional results in demanding manufacturing environments. Proficient in various aspects of operations management, including production planning, scheduling, inventory control, and equipment maintenance.

Education

Bachelor’s degree in Engineering

April 2016

Skills

- Team Leadership

- Operations Management

- Production Planning and Scheduling

- Quality Assurance and Control

- Inventory Management

- Equipment Maintenance

Work Experience

Charge Hand

- Performed regular inspections of equipment and machinery, ensuring compliance with safety regulations and maintenance schedules.

- Managed inventory levels, minimizing waste and optimizing resource allocation.

- Collaborated with engineers and designers to develop and implement process improvements.

- Provided technical support and guidance to team members, fostering a culture of continuous improvement.

Charge Hand

- Supervised and motivated a team of technicians, ensuring adherence to safety protocols and efficient completion of tasks.

- Developed and implemented training programs to enhance team skills and productivity.

- Established and maintained effective communication channels with team members, supervisors, and customers.

- Utilized Six Sigma methodologies to identify and resolve production inefficiencies, resulting in a 15% increase in output.

Accomplishments

- Successfully led a team of 15 technicians in a major plant expansion project, resulting in a 15% increase in production capacity

- Established a standardized training program for new charge hands, improving onboarding time by 25%

- Optimized production processes through process mapping and automation, leading to a 10% reduction in operating costs

- Developed and implemented a safety management system that reduced workplace incidents by 30%

- Led a crossfunctional team in developing a new product line that generated over $1 million in revenue

Awards

- Received the National Safety Excellence Award for implementing an innovative safety program that reduced workplace accidents by 20%

- Awarded the Supervisor of the Year for mentoring and developing a team that achieved exceptional performance levels

- Recognized for outstanding leadership in managing a team that consistently exceeded production targets

- Received the Lean Manufacturing Excellence Award for implementing continuous improvement initiatives that resulted in a 20% increase in efficiency

Certificates

- Certified Production Technician (CPT)

- Certified Quality Inspector (CQI)

- Certified Manufacturing Engineer (CMfgE)

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Charge Hand

- Quantify your accomplishments with specific metrics and outcomes whenever possible.

- Highlight your leadership and management skills, emphasizing your ability to motivate and develop teams.

- Showcase your technical expertise in production planning, scheduling, and quality control.

- Demonstrate your commitment to safety by describing your experience in implementing and maintaining safety protocols.

Essential Experience Highlights for a Strong Charge Hand Resume

- Lead and motivate teams of production technicians and operators to achieve operational targets and ensure smooth workflow

- Plan, schedule, and monitor production operations to maximize efficiency, minimize downtime, and meet customer demands

- Establish and implement quality control procedures to ensure products meet specifications and industry standards

- Perform regular equipment maintenance and troubleshooting to prevent breakdowns and ensure optimal performance

- Manage inventory levels, coordinate with suppliers, and implement cost-effective procurement strategies

- Contribute to continuous improvement initiatives by analyzing production data, identifying bottlenecks, and implementing process optimizations

- Maintain a safe and compliant work environment by enforcing safety protocols, conducting safety audits, and providing training to staff

Frequently Asked Questions (FAQ’s) For Charge Hand

What are the primary responsibilities of a Charge Hand?

Charge Hands are responsible for leading and supervising production teams, ensuring efficient operations, maintaining quality standards, and implementing safety protocols.

What skills and qualifications are required to become a Charge Hand?

Typically, Charge Hands require a combination of technical expertise in production processes, leadership and management skills, and a strong understanding of quality and safety standards.

What industries employ Charge Hands?

Charge Hands are employed in various manufacturing industries, including automotive, electronics, pharmaceuticals, and food processing.

What is the career path for a Charge Hand?

Charge Hands can progress to supervisory or managerial roles, such as Production Supervisor or Operations Manager.

What is the average salary for a Charge Hand?

The average salary for a Charge Hand varies depending on experience, industry, and location, but typically ranges from $50,000 to $80,000 per year.

What are the challenges faced by Charge Hands?

Charge Hands often face challenges such as managing production deadlines, ensuring product quality, motivating staff, and maintaining a safe work environment.