Are you a seasoned Chemical Recovery Operator seeking a new career path? Discover our professionally built Chemical Recovery Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

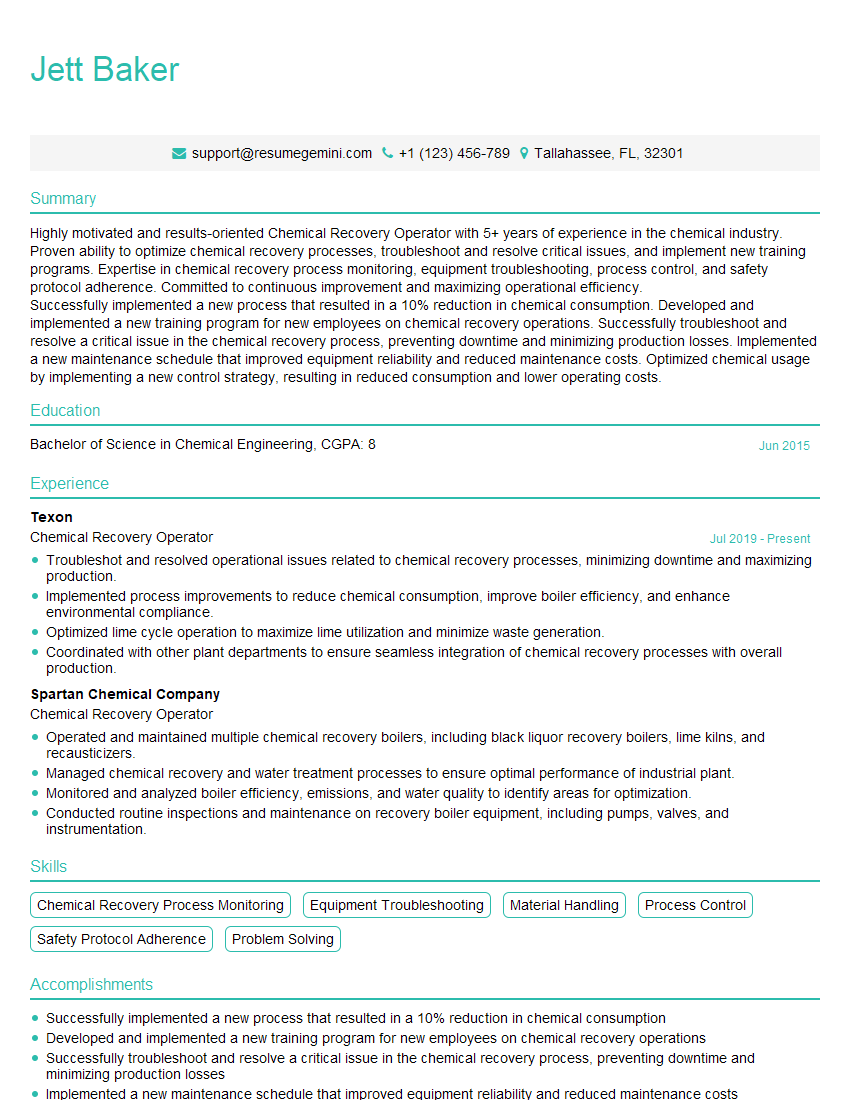

Jett Baker

Chemical Recovery Operator

Summary

Highly motivated and results-oriented Chemical Recovery Operator with 5+ years of experience in the chemical industry. Proven ability to optimize chemical recovery processes, troubleshoot and resolve critical issues, and implement new training programs. Expertise in chemical recovery process monitoring, equipment troubleshooting, process control, and safety protocol adherence. Committed to continuous improvement and maximizing operational efficiency.

Successfully implemented a new process that resulted in a 10% reduction in chemical consumption. Developed and implemented a new training program for new employees on chemical recovery operations. Successfully troubleshoot and resolve a critical issue in the chemical recovery process, preventing downtime and minimizing production losses. Implemented a new maintenance schedule that improved equipment reliability and reduced maintenance costs. Optimized chemical usage by implementing a new control strategy, resulting in reduced consumption and lower operating costs.

Education

Bachelor of Science in Chemical Engineering

June 2015

Skills

- Chemical Recovery Process Monitoring

- Equipment Troubleshooting

- Material Handling

- Process Control

- Safety Protocol Adherence

- Problem Solving

Work Experience

Chemical Recovery Operator

- Troubleshot and resolved operational issues related to chemical recovery processes, minimizing downtime and maximizing production.

- Implemented process improvements to reduce chemical consumption, improve boiler efficiency, and enhance environmental compliance.

- Optimized lime cycle operation to maximize lime utilization and minimize waste generation.

- Coordinated with other plant departments to ensure seamless integration of chemical recovery processes with overall production.

Chemical Recovery Operator

- Operated and maintained multiple chemical recovery boilers, including black liquor recovery boilers, lime kilns, and recausticizers.

- Managed chemical recovery and water treatment processes to ensure optimal performance of industrial plant.

- Monitored and analyzed boiler efficiency, emissions, and water quality to identify areas for optimization.

- Conducted routine inspections and maintenance on recovery boiler equipment, including pumps, valves, and instrumentation.

Accomplishments

- Successfully implemented a new process that resulted in a 10% reduction in chemical consumption

- Developed and implemented a new training program for new employees on chemical recovery operations

- Successfully troubleshoot and resolve a critical issue in the chemical recovery process, preventing downtime and minimizing production losses

- Implemented a new maintenance schedule that improved equipment reliability and reduced maintenance costs

- Optimized chemical usage by implementing a new control strategy, resulting in reduced consumption and lower operating costs

Awards

- Received the Employee of the Year award for outstanding performance in maintaining and operating chemical recovery equipment

- Recognized for exceptional safety practices, maintaining a spotless safety record throughout the year

- Received a certification in the operation of advanced chemical recovery systems

- Recognized for dedication to safety and compliance, consistently exceeding industry standards

Certificates

- Certified Chemical Recovery Operator

- OSHA 30Hour Hazardous Waste Operations and Emergency Response

- EPA Part 503 Biosolids Management

- ANSI/ASSP Safety Manager

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Chemical Recovery Operator

- Highlight your technical skills and experience in chemical recovery processes.

- Quantify your accomplishments with specific metrics and results.

- Demonstrate your problem-solving abilities and ability to work independently.

- Emphasize your commitment to safety and compliance.

- Proofread your resume carefully for any errors.

Essential Experience Highlights for a Strong Chemical Recovery Operator Resume

- Monitor and control chemical recovery processes to ensure optimal performance and efficiency

- Troubleshoot and resolve equipment malfunctions and process issues to minimize downtime and production losses

- Handle and transfer hazardous chemicals safely and in compliance with established protocols

- Operate and maintain chemical recovery equipment, including pumps, tanks, and filtration systems

- Implement and maintain quality control measures to ensure the quality of recovered chemicals

- Adhere to all safety regulations and protocols to ensure a safe working environment

- Supervise and train new employees on chemical recovery operations

Frequently Asked Questions (FAQ’s) For Chemical Recovery Operator

What is the role of a Chemical Recovery Operator?

A Chemical Recovery Operator is responsible for monitoring, controlling, and troubleshooting chemical recovery processes in industrial settings. They ensure the efficient recovery of chemicals, maintain equipment, and adhere to safety protocols.

What are the key skills required for a Chemical Recovery Operator?

Key skills for a Chemical Recovery Operator include chemical recovery process monitoring, equipment troubleshooting, material handling, process control, safety protocol adherence, and problem-solving.

What industries employ Chemical Recovery Operators?

Chemical Recovery Operators are employed in various industries, including chemical manufacturing, pharmaceuticals, pulp and paper, and wastewater treatment.

What is the career outlook for Chemical Recovery Operators?

The career outlook for Chemical Recovery Operators is expected to grow in the coming years due to increasing demand for chemical products and the need for efficient and environmentally friendly chemical recovery processes.

What are the educational requirements for a Chemical Recovery Operator?

Most Chemical Recovery Operators hold a high school diploma or equivalent, with some employers preferring candidates with a technical degree or certification in chemical engineering or a related field.

What are the safety considerations for Chemical Recovery Operators?

Chemical Recovery Operators must adhere to strict safety protocols to handle and work with hazardous chemicals. They are required to wear protective gear, follow proper procedures, and be aware of potential hazards associated with chemical recovery processes.

How can I advance my career as a Chemical Recovery Operator?

To advance their careers, Chemical Recovery Operators can pursue further education or specialized training, gain experience in different areas of chemical recovery, and demonstrate their ability to take on additional responsibilities.

What are the typical working conditions for Chemical Recovery Operators?

Chemical Recovery Operators typically work in industrial settings, often in shifts. They may be exposed to hazardous chemicals, noise, and other potential hazards, and must be able to work independently and as part of a team.