Are you a seasoned Chronometer Assembler and Adjuster seeking a new career path? Discover our professionally built Chronometer Assembler and Adjuster Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

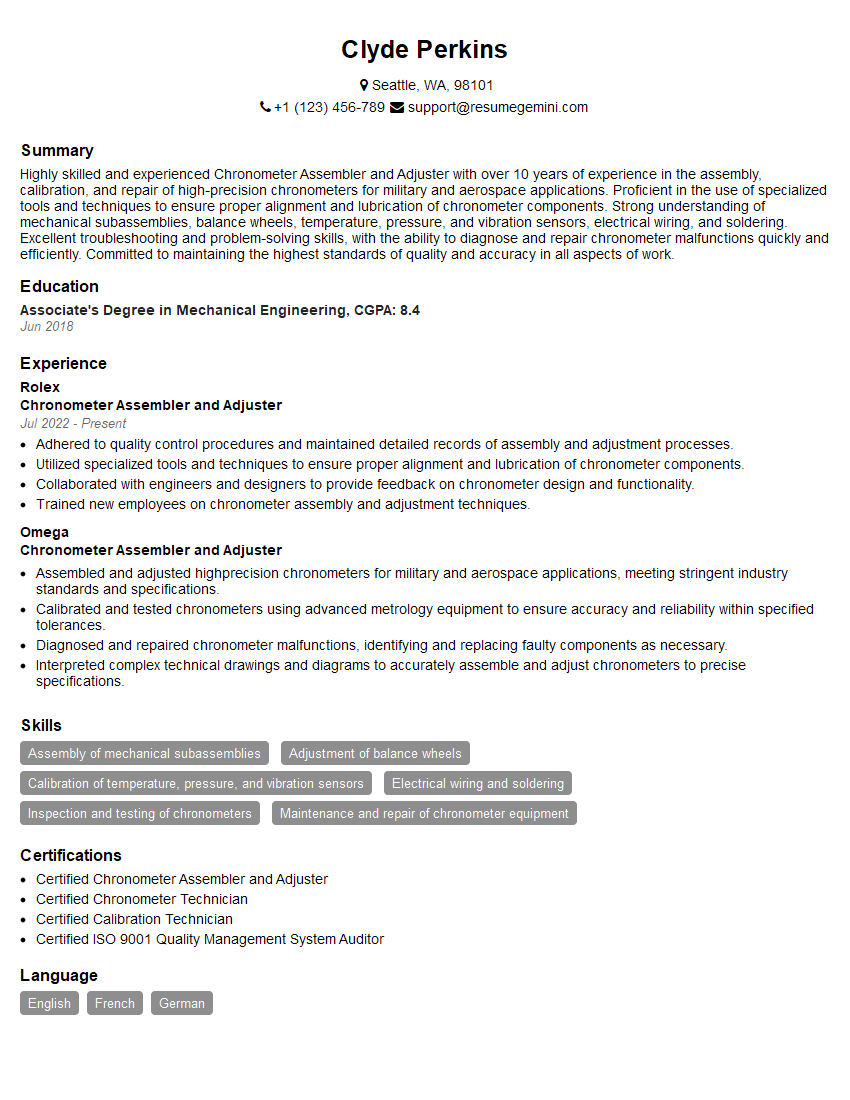

Clyde Perkins

Chronometer Assembler and Adjuster

Summary

Highly skilled and experienced Chronometer Assembler and Adjuster with over 10 years of experience in the assembly, calibration, and repair of high-precision chronometers for military and aerospace applications. Proficient in the use of specialized tools and techniques to ensure proper alignment and lubrication of chronometer components. Strong understanding of mechanical subassemblies, balance wheels, temperature, pressure, and vibration sensors, electrical wiring, and soldering. Excellent troubleshooting and problem-solving skills, with the ability to diagnose and repair chronometer malfunctions quickly and efficiently. Committed to maintaining the highest standards of quality and accuracy in all aspects of work.

Education

Associate’s Degree in Mechanical Engineering

June 2018

Skills

- Assembly of mechanical subassemblies

- Adjustment of balance wheels

- Calibration of temperature, pressure, and vibration sensors

- Electrical wiring and soldering

- Inspection and testing of chronometers

- Maintenance and repair of chronometer equipment

Work Experience

Chronometer Assembler and Adjuster

- Adhered to quality control procedures and maintained detailed records of assembly and adjustment processes.

- Utilized specialized tools and techniques to ensure proper alignment and lubrication of chronometer components.

- Collaborated with engineers and designers to provide feedback on chronometer design and functionality.

- Trained new employees on chronometer assembly and adjustment techniques.

Chronometer Assembler and Adjuster

- Assembled and adjusted highprecision chronometers for military and aerospace applications, meeting stringent industry standards and specifications.

- Calibrated and tested chronometers using advanced metrology equipment to ensure accuracy and reliability within specified tolerances.

- Diagnosed and repaired chronometer malfunctions, identifying and replacing faulty components as necessary.

- Interpreted complex technical drawings and diagrams to accurately assemble and adjust chronometers to precise specifications.

Certificates

- Certified Chronometer Assembler and Adjuster

- Certified Chronometer Technician

- Certified Calibration Technician

- Certified ISO 9001 Quality Management System Auditor

Languages

- English

- French

- German

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Chronometer Assembler and Adjuster

- Highlight your experience in assembling and adjusting high-precision chronometers for military and aerospace applications.

- Emphasize your skills in calibration and testing using advanced metrology equipment.

- Showcase your ability to diagnose and repair chronometer malfunctions, and your knowledge of mechanical subassemblies and electronic components.

- Mention your experience in interpreting complex technical drawings and diagrams, and your adherence to quality control procedures.

- Include keywords such as ‘chronometer assembler’, ‘chronometer adjuster’, ‘metrology’, ‘calibration’, ‘repair’, ‘mechanical subassemblies’, and ‘quality control’ in your resume.

Essential Experience Highlights for a Strong Chronometer Assembler and Adjuster Resume

- Assembled and adjusted high-precision chronometers for military and aerospace applications, meeting stringent industry standards and specifications.

- Calibrated and tested chronometers using advanced metrology equipment to ensure accuracy and reliability within specified tolerances.

- Diagnosed and repaired chronometer malfunctions, identifying and replacing faulty components as necessary.

- Interpreted complex technical drawings and diagrams to accurately assemble and adjust chronometers to precise specifications.

- Adhered to quality control procedures and maintained detailed records of assembly and adjustment processes.

- Utilized specialized tools and techniques to ensure proper alignment and lubrication of chronometer components.

- Collaborated with engineers and designers to provide feedback on chronometer design and functionality.

Frequently Asked Questions (FAQ’s) For Chronometer Assembler and Adjuster

What is a chronometer?

A chronometer is a precision timekeeping device that is used to measure time accurately. It is often used in navigation, astronomy, and scientific research. Chronometers are typically more accurate than regular watches and are designed to withstand harsh conditions.

What does a chronometer assembler and adjuster do?

A chronometer assembler and adjuster is responsible for assembling and adjusting chronometers to ensure that they meet the required accuracy standards. They may also calibrate and test chronometers to ensure that they are functioning properly. Some chronometer assemblers and adjusters may also be responsible for repairing chronometers that have been damaged.

What skills are required to be a chronometer assembler and adjuster?

Chronometer assemblers and adjusters typically need to have a strong understanding of mechanical engineering and electronics. They should also be able to work with precision tools and equipment. Additionally, they should have good problem-solving skills and be able to work independently.

What is the job outlook for chronometer assemblers and adjusters?

The job outlook for chronometer assemblers and adjusters is expected to be good in the coming years. The demand for precision timekeeping devices is expected to increase as the use of technology continues to grow. Additionally, the aging population is expected to increase the demand for healthcare devices that require precision timekeeping.

How can I become a chronometer assembler and adjuster?

There are a few different ways to become a chronometer assembler and adjuster. One way is to complete a formal training program. Another way is to learn on the job by working under the supervision of an experienced chronometer assembler and adjuster. Additionally, there are a number of online resources that can provide you with information on how to become a chronometer assembler and adjuster.

What is the salary range for chronometer assemblers and adjusters?

The salary range for chronometer assemblers and adjusters can vary depending on their experience, skills, and location. However, the median salary for chronometer assemblers and adjusters is around $40,000 per year.