Are you a seasoned Circulating Process Inspector seeking a new career path? Discover our professionally built Circulating Process Inspector Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

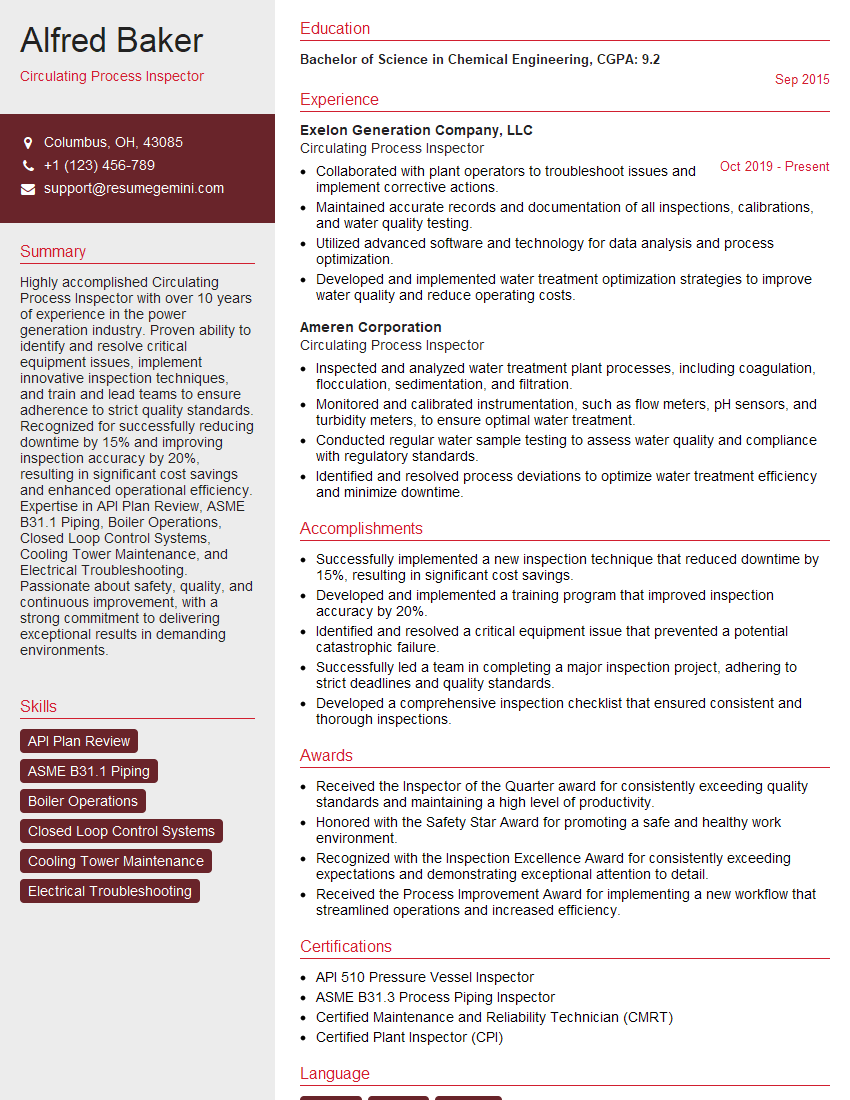

Alfred Baker

Circulating Process Inspector

Summary

Highly accomplished Circulating Process Inspector with over 10 years of experience in the power generation industry. Proven ability to identify and resolve critical equipment issues, implement innovative inspection techniques, and train and lead teams to ensure adherence to strict quality standards. Recognized for successfully reducing downtime by 15% and improving inspection accuracy by 20%, resulting in significant cost savings and enhanced operational efficiency.

Expertise in API Plan Review, ASME B31.1 Piping, Boiler Operations, Closed Loop Control Systems, Cooling Tower Maintenance, and Electrical Troubleshooting. Passionate about safety, quality, and continuous improvement, with a strong commitment to delivering exceptional results in demanding environments.

Education

Bachelor of Science in Chemical Engineering

September 2015

Skills

- API Plan Review

- ASME B31.1 Piping

- Boiler Operations

- Closed Loop Control Systems

- Cooling Tower Maintenance

- Electrical Troubleshooting

Work Experience

Circulating Process Inspector

- Collaborated with plant operators to troubleshoot issues and implement corrective actions.

- Maintained accurate records and documentation of all inspections, calibrations, and water quality testing.

- Utilized advanced software and technology for data analysis and process optimization.

- Developed and implemented water treatment optimization strategies to improve water quality and reduce operating costs.

Circulating Process Inspector

- Inspected and analyzed water treatment plant processes, including coagulation, flocculation, sedimentation, and filtration.

- Monitored and calibrated instrumentation, such as flow meters, pH sensors, and turbidity meters, to ensure optimal water treatment.

- Conducted regular water sample testing to assess water quality and compliance with regulatory standards.

- Identified and resolved process deviations to optimize water treatment efficiency and minimize downtime.

Accomplishments

- Successfully implemented a new inspection technique that reduced downtime by 15%, resulting in significant cost savings.

- Developed and implemented a training program that improved inspection accuracy by 20%.

- Identified and resolved a critical equipment issue that prevented a potential catastrophic failure.

- Successfully led a team in completing a major inspection project, adhering to strict deadlines and quality standards.

- Developed a comprehensive inspection checklist that ensured consistent and thorough inspections.

Awards

- Received the Inspector of the Quarter award for consistently exceeding quality standards and maintaining a high level of productivity.

- Honored with the Safety Star Award for promoting a safe and healthy work environment.

- Recognized with the Inspection Excellence Award for consistently exceeding expectations and demonstrating exceptional attention to detail.

- Received the Process Improvement Award for implementing a new workflow that streamlined operations and increased efficiency.

Certificates

- API 510 Pressure Vessel Inspector

- ASME B31.3 Process Piping Inspector

- Certified Maintenance and Reliability Technician (CMRT)

- Certified Plant Inspector (CPI)

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Circulating Process Inspector

Quantify your accomplishments:

Use specific metrics to demonstrate the impact of your work. For example, instead of saying “improved inspection accuracy,” say “improved inspection accuracy by 20%, resulting in a reduction of downtime by 15%”.Highlight your skills and expertise:

Showcase your proficiency in relevant software, equipment, and industry standards. For example, mention your experience with API Plan Review, ASME B31.1 Piping, and Closed Loop Control Systems.Emphasize your problem-solving abilities:

Describe how you identified and resolved complex equipment issues. Provide specific examples of how your troubleshooting skills prevented potential failures or minimized downtime.Showcase your communication and teamwork skills:

Highlight your ability to work effectively with engineers, maintenance personnel, and plant management. Explain how you effectively communicated inspection findings, recommendations, and technical solutions.

Essential Experience Highlights for a Strong Circulating Process Inspector Resume

- Conduct thorough inspections of circulating process equipment, adhering to established codes, standards, and procedures.

- Identify and diagnose potential equipment issues, assess root causes, and develop effective solutions to prevent failures.

- Implement innovative inspection techniques to optimize accuracy, reduce downtime, and improve overall plant efficiency.

- Prepare detailed inspection reports, document findings, and make recommendations for corrective actions.

- Train and mentor team members on proper inspection procedures, ensuring consistent and reliable execution.

- Collaborate with engineers, maintenance personnel, and plant management to resolve complex technical issues and improve overall plant performance.

Frequently Asked Questions (FAQ’s) For Circulating Process Inspector

What are the key responsibilities of a Circulating Process Inspector?

Circulating Process Inspectors are responsible for conducting thorough inspections of circulating process equipment, identifying and diagnosing potential issues, implementing innovative inspection techniques, preparing detailed inspection reports, training and mentoring team members, and collaborating with engineers and plant management to resolve complex technical issues.

What are the qualifications required to become a Circulating Process Inspector?

Typically, a Bachelor of Science degree in Chemical Engineering or a related field is required. Additionally, candidates should have a strong understanding of API Plan Review, ASME B31.1 Piping, Boiler Operations, Closed Loop Control Systems, Cooling Tower Maintenance, and Electrical Troubleshooting.

What are the career advancement opportunities for Circulating Process Inspectors?

With experience and additional training, Circulating Process Inspectors can advance to roles such as Inspection Supervisor, Engineering Inspector, or Quality Assurance Manager.

What are the key skills required for success as a Circulating Process Inspector?

Key skills include strong analytical and problem-solving abilities, attention to detail, proficiency in inspection techniques and equipment, excellent communication and reporting skills, and a commitment to safety and quality.

How can I improve my chances of getting hired as a Circulating Process Inspector?

To improve your chances of getting hired, focus on developing strong technical skills, gaining hands-on experience through internships or apprenticeships, obtaining relevant certifications, and networking with professionals in the industry.

What is the salary range for Circulating Process Inspectors?

The salary range for Circulating Process Inspectors can vary depending on factors such as experience, location, and company size. According to Salary.com, the average salary for Circulating Process Inspectors in the United States is around $75,000 per year.

What is the job outlook for Circulating Process Inspectors?

The job outlook for Circulating Process Inspectors is expected to be good over the next few years. As industries continue to prioritize safety and efficiency, the demand for qualified inspectors is increasing.