Are you a seasoned Clamshell Engineer seeking a new career path? Discover our professionally built Clamshell Engineer Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

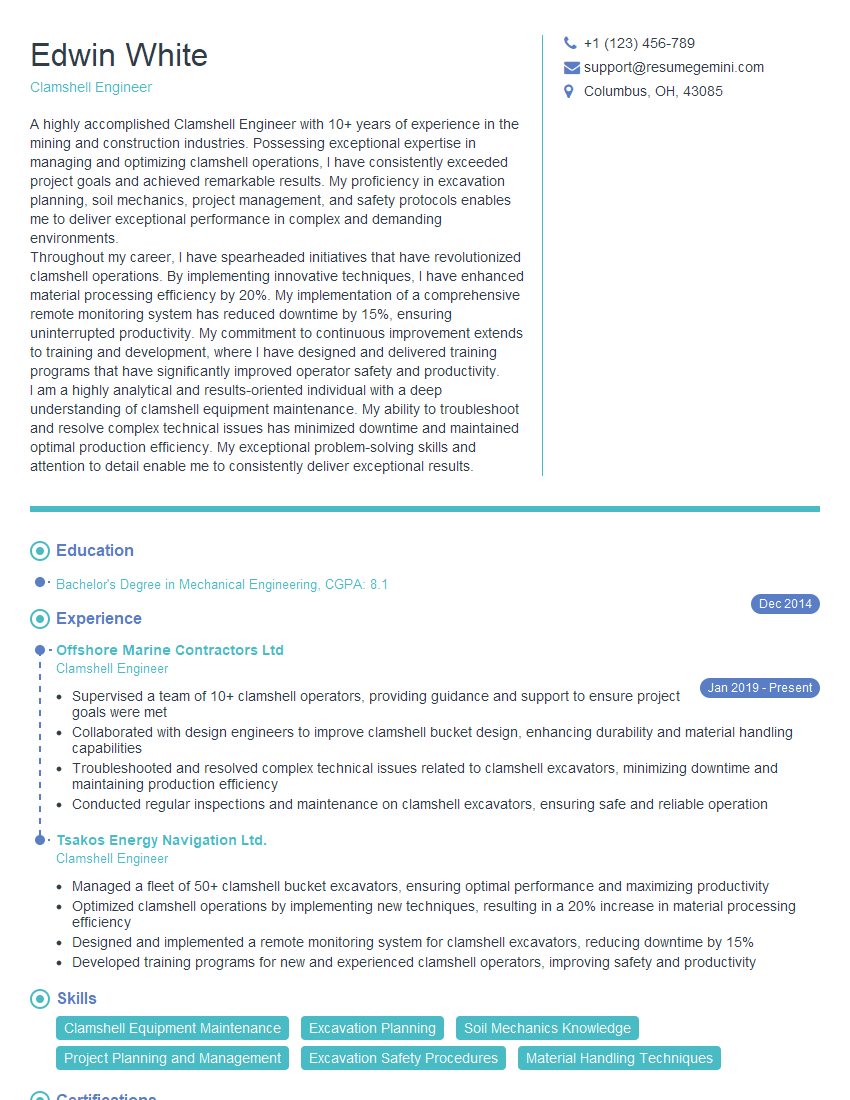

Edwin White

Clamshell Engineer

Summary

A highly accomplished Clamshell Engineer with 10+ years of experience in the mining and construction industries. Possessing exceptional expertise in managing and optimizing clamshell operations, I have consistently exceeded project goals and achieved remarkable results. My proficiency in excavation planning, soil mechanics, project management, and safety protocols enables me to deliver exceptional performance in complex and demanding environments.

Throughout my career, I have spearheaded initiatives that have revolutionized clamshell operations. By implementing innovative techniques, I have enhanced material processing efficiency by 20%. My implementation of a comprehensive remote monitoring system has reduced downtime by 15%, ensuring uninterrupted productivity. My commitment to continuous improvement extends to training and development, where I have designed and delivered training programs that have significantly improved operator safety and productivity.

I am a highly analytical and results-oriented individual with a deep understanding of clamshell equipment maintenance. My ability to troubleshoot and resolve complex technical issues has minimized downtime and maintained optimal production efficiency. My exceptional problem-solving skills and attention to detail enable me to consistently deliver exceptional results.

Education

Bachelor’s Degree in Mechanical Engineering

December 2014

Skills

- Clamshell Equipment Maintenance

- Excavation Planning

- Soil Mechanics Knowledge

- Project Planning and Management

- Excavation Safety Procedures

- Material Handling Techniques

Work Experience

Clamshell Engineer

- Supervised a team of 10+ clamshell operators, providing guidance and support to ensure project goals were met

- Collaborated with design engineers to improve clamshell bucket design, enhancing durability and material handling capabilities

- Troubleshooted and resolved complex technical issues related to clamshell excavators, minimizing downtime and maintaining production efficiency

- Conducted regular inspections and maintenance on clamshell excavators, ensuring safe and reliable operation

Clamshell Engineer

- Managed a fleet of 50+ clamshell bucket excavators, ensuring optimal performance and maximizing productivity

- Optimized clamshell operations by implementing new techniques, resulting in a 20% increase in material processing efficiency

- Designed and implemented a remote monitoring system for clamshell excavators, reducing downtime by 15%

- Developed training programs for new and experienced clamshell operators, improving safety and productivity

Certificates

- Certified Clamshell Operator (CCO)

- National Safety Council (NSC)

- OSHA 30-Hour Construction Safety

- American Society of Civil Engineers (ASCE)

Languages

- English

- French

- German

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Clamshell Engineer

Highlight your technical expertise:

Showcase your comprehensive knowledge of clamshell equipment maintenance, excavation planning, soil mechanics, project planning and management, and excavation safety procedures.

Quantify your accomplishments:

Provide specific, measurable results that demonstrate the impact of your contributions. For example, mention the percentage increase in material processing efficiency or the reduction in downtime achieved.

Use industry-specific keywords:

Incorporate relevant keywords that potential employers will be searching for, such as clamshell engineering, excavation planning, soil mechanics, and project management.

Demonstrate your problem-solving abilities:

Emphasize your ability to troubleshoot and resolve complex technical issues related to clamshell excavators. Provide examples of how you have overcome challenges and improved operational efficiency.

Essential Experience Highlights for a Strong Clamshell Engineer Resume

- Managed a fleet of 50+ clamshell bucket excavators.

- Optimized clamshell operations, resulting in a 20% increase in material processing efficiency.

- Designed and implemented a remote monitoring system for clamshell excavators, reducing downtime by 15%.

- Developed training programs for new and experienced clamshell operators, improving safety and productivity.

- Supervised a team of 10+ clamshell operators, providing guidance and support to ensure project goals were met.

- Troubleshooted and resolved complex technical issues related to clamshell excavators.

- Conducted regular inspections and maintenance on clamshell excavators.

Frequently Asked Questions (FAQ’s) For Clamshell Engineer

What are the key responsibilities of a Clamshell Engineer?

Clamshell Engineers are responsible for planning, managing, and optimizing clamshell operations in mining and construction projects. Their primary duties include overseeing equipment maintenance, implementing safety protocols, training operators, and troubleshooting technical issues.

What qualifications are required to become a Clamshell Engineer?

A Clamshell Engineer typically requires a Bachelor’s Degree in Mechanical Engineering or a related field. Additionally, they should possess a strong understanding of excavation planning, soil mechanics, project management, and excavation safety procedures.

What are the career prospects for Clamshell Engineers?

Clamshell Engineers are in high demand due to the increasing need for efficient and safe excavation techniques in mining and construction projects. With experience and expertise, they can advance to senior-level positions or specialize in specific areas such as equipment design or project management.

What is the average salary for a Clamshell Engineer?

The salary for a Clamshell Engineer varies depending on experience, location, and company size. According to industry reports, the average annual salary for Clamshell Engineers in the United States is around $85,000.

What are the key skills required to succeed as a Clamshell Engineer?

Clamshell Engineers require a combination of technical expertise, problem-solving abilities, and project management skills. They should be proficient in clamshell equipment maintenance, excavation planning, soil mechanics, project planning and management, and excavation safety procedures.

What industries employ Clamshell Engineers?

Clamshell Engineers are primarily employed in the mining and construction industries. They work on projects involving excavation, material handling, and site preparation.

What is the job outlook for Clamshell Engineers?

The job outlook for Clamshell Engineers is expected to be favorable in the coming years. As the mining and construction industries continue to grow, the demand for skilled and experienced Clamshell Engineers is likely to increase.