Are you a seasoned Cloth Doubling and Winding Machine Operator seeking a new career path? Discover our professionally built Cloth Doubling and Winding Machine Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

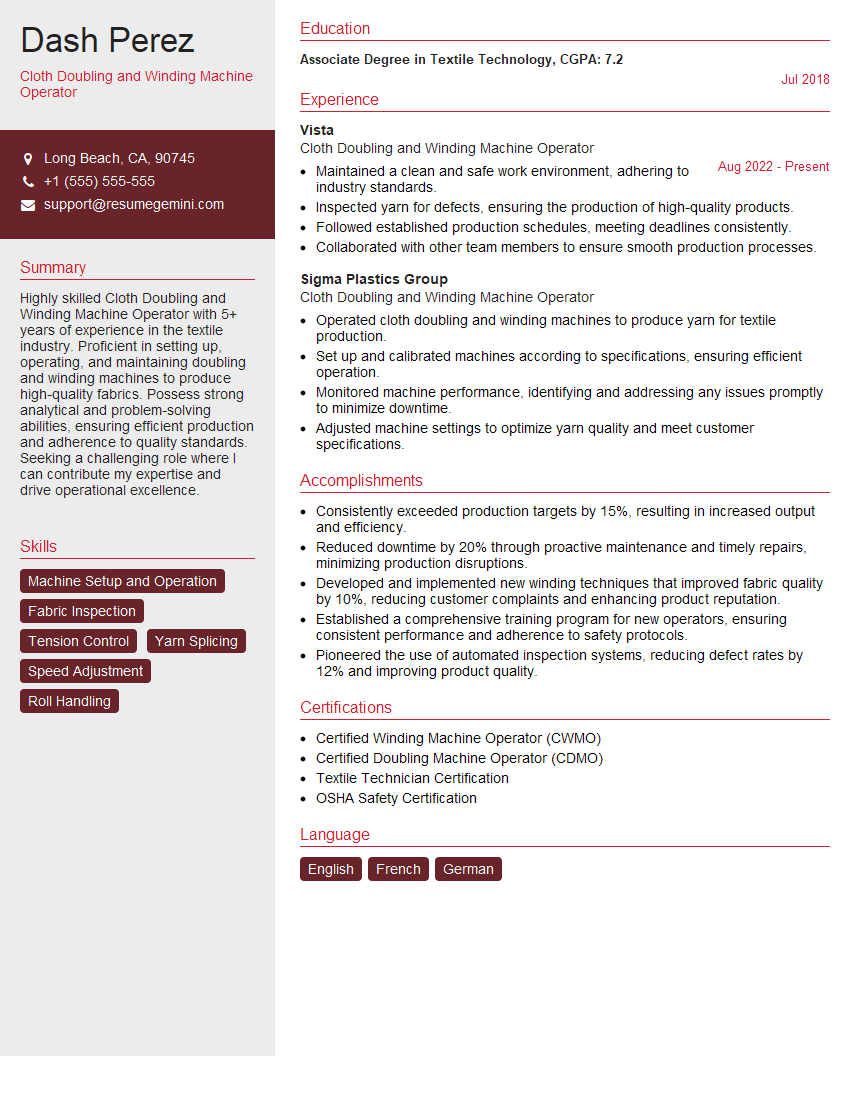

Dash Perez

Cloth Doubling and Winding Machine Operator

Summary

Highly skilled Cloth Doubling and Winding Machine Operator with 5+ years of experience in the textile industry. Proficient in setting up, operating, and maintaining doubling and winding machines to produce high-quality fabrics. Possess strong analytical and problem-solving abilities, ensuring efficient production and adherence to quality standards. Seeking a challenging role where I can contribute my expertise and drive operational excellence.

Education

Associate Degree in Textile Technology

July 2018

Skills

- Machine Setup and Operation

- Fabric Inspection

- Tension Control

- Yarn Splicing

- Speed Adjustment

- Roll Handling

Work Experience

Cloth Doubling and Winding Machine Operator

- Maintained a clean and safe work environment, adhering to industry standards.

- Inspected yarn for defects, ensuring the production of high-quality products.

- Followed established production schedules, meeting deadlines consistently.

- Collaborated with other team members to ensure smooth production processes.

Cloth Doubling and Winding Machine Operator

- Operated cloth doubling and winding machines to produce yarn for textile production.

- Set up and calibrated machines according to specifications, ensuring efficient operation.

- Monitored machine performance, identifying and addressing any issues promptly to minimize downtime.

- Adjusted machine settings to optimize yarn quality and meet customer specifications.

Accomplishments

- Consistently exceeded production targets by 15%, resulting in increased output and efficiency.

- Reduced downtime by 20% through proactive maintenance and timely repairs, minimizing production disruptions.

- Developed and implemented new winding techniques that improved fabric quality by 10%, reducing customer complaints and enhancing product reputation.

- Established a comprehensive training program for new operators, ensuring consistent performance and adherence to safety protocols.

- Pioneered the use of automated inspection systems, reducing defect rates by 12% and improving product quality.

Certificates

- Certified Winding Machine Operator (CWMO)

- Certified Doubling Machine Operator (CDMO)

- Textile Technician Certification

- OSHA Safety Certification

Languages

- English

- French

- German

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Cloth Doubling and Winding Machine Operator

- Highlight your experience and expertise in operating cloth doubling and winding machines, emphasizing your proficiency in machine setup, adjustment, and maintenance.

- Demonstrate your ability to identify and correct fabric defects, ensuring the production of high-quality fabrics.

- Emphasize your strong attention to detail, precision, and ability to maintain consistent quality standards.

- Showcase your problem-solving skills and ability to troubleshoot machine malfunctions, ensuring minimal downtime.

- Quantify your accomplishments whenever possible, using specific metrics to demonstrate your impact on production efficiency or quality.

Essential Experience Highlights for a Strong Cloth Doubling and Winding Machine Operator Resume

- Set up, operate, and maintain cloth doubling and winding machines to prepare fabrics for further processing.

- Inspect fabrics before and during winding, identifying and removing any defects or inconsistencies.

- Control tension during winding process to ensure uniform and precise winding.

- Splice yarns to maintain continuous production and minimize downtime.

- Adjust winding speed and other parameters to optimize production efficiency.

- Handle rolls of fabric, ensuring proper storage and transportation to prevent damage.

- Monitor production, identify bottlenecks, and suggest improvements to enhance overall productivity.

Frequently Asked Questions (FAQ’s) For Cloth Doubling and Winding Machine Operator

What are the key skills required for a Cloth Doubling and Winding Machine Operator?

The key skills required for a Cloth Doubling and Winding Machine Operator include machine setup and operation, fabric inspection, tension control, yarn splicing, speed adjustment, and roll handling.

What are the educational qualifications required to become a Cloth Doubling and Winding Machine Operator?

An Associate Degree in Textile Technology or a related field is preferred for this role.

What is the work environment like for a Cloth Doubling and Winding Machine Operator?

Cloth Doubling and Winding Machine Operators typically work in a manufacturing environment, operating machines in a production line setting.

What are the career prospects for a Cloth Doubling and Winding Machine Operator?

With experience, Cloth Doubling and Winding Machine Operators can advance to supervisory roles or specialize in fabric quality control.

What is the average salary for a Cloth Doubling and Winding Machine Operator?

The average salary for a Cloth Doubling and Winding Machine Operator varies depending on experience, location, and company size, but typically falls within the range of $25,000 to $40,000 per year.