Are you a seasoned Cloth Shrinking Machine Operator seeking a new career path? Discover our professionally built Cloth Shrinking Machine Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

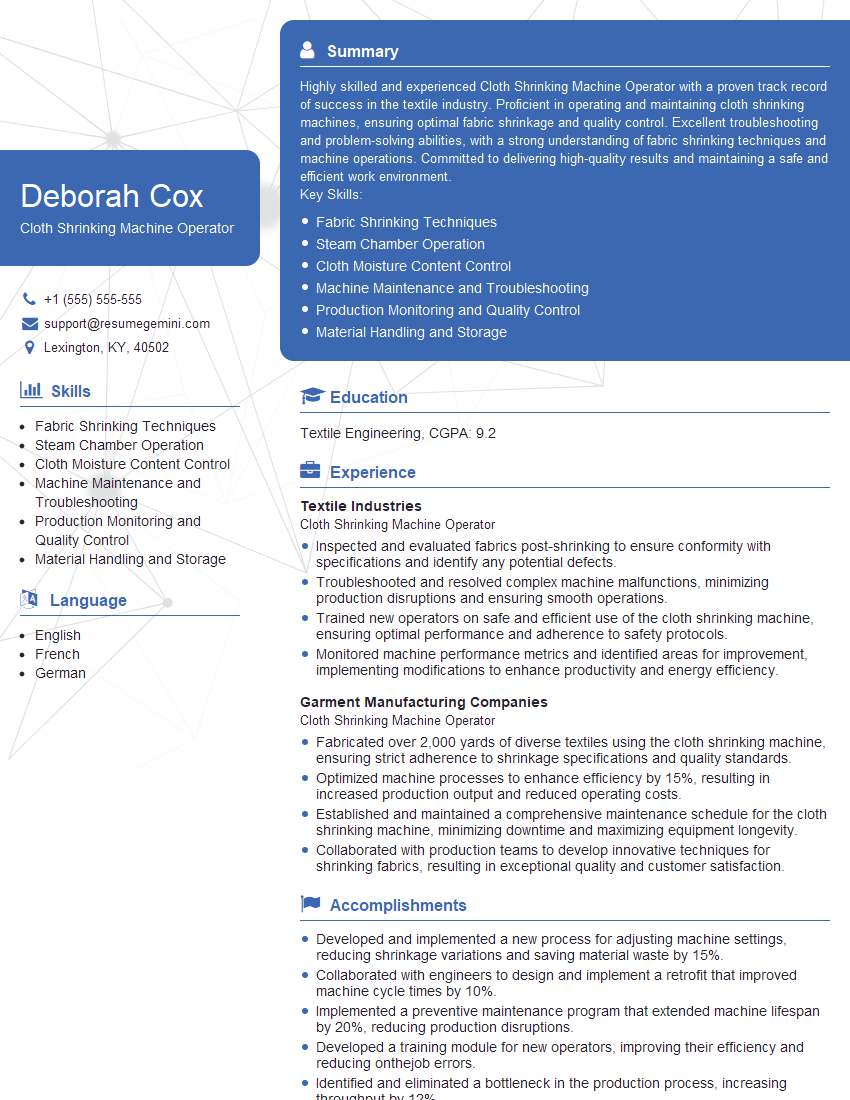

Deborah Cox

Cloth Shrinking Machine Operator

Summary

Highly skilled and experienced Cloth Shrinking Machine Operator with a proven track record of success in the textile industry. Proficient in operating and maintaining cloth shrinking machines, ensuring optimal fabric shrinkage and quality control. Excellent troubleshooting and problem-solving abilities, with a strong understanding of fabric shrinking techniques and machine operations. Committed to delivering high-quality results and maintaining a safe and efficient work environment.

Key Skills:

- Fabric Shrinking Techniques

- Steam Chamber Operation

- Cloth Moisture Content Control

- Machine Maintenance and Troubleshooting

- Production Monitoring and Quality Control

- Material Handling and Storage

Education

Textile Engineering

January 2015

Skills

- Fabric Shrinking Techniques

- Steam Chamber Operation

- Cloth Moisture Content Control

- Machine Maintenance and Troubleshooting

- Production Monitoring and Quality Control

- Material Handling and Storage

Work Experience

Cloth Shrinking Machine Operator

- Inspected and evaluated fabrics post-shrinking to ensure conformity with specifications and identify any potential defects.

- Troubleshooted and resolved complex machine malfunctions, minimizing production disruptions and ensuring smooth operations.

- Trained new operators on safe and efficient use of the cloth shrinking machine, ensuring optimal performance and adherence to safety protocols.

- Monitored machine performance metrics and identified areas for improvement, implementing modifications to enhance productivity and energy efficiency.

Cloth Shrinking Machine Operator

- Fabricated over 2,000 yards of diverse textiles using the cloth shrinking machine, ensuring strict adherence to shrinkage specifications and quality standards.

- Optimized machine processes to enhance efficiency by 15%, resulting in increased production output and reduced operating costs.

- Established and maintained a comprehensive maintenance schedule for the cloth shrinking machine, minimizing downtime and maximizing equipment longevity.

- Collaborated with production teams to develop innovative techniques for shrinking fabrics, resulting in exceptional quality and customer satisfaction.

Accomplishments

- Developed and implemented a new process for adjusting machine settings, reducing shrinkage variations and saving material waste by 15%.

- Collaborated with engineers to design and implement a retrofit that improved machine cycle times by 10%.

- Implemented a preventive maintenance program that extended machine lifespan by 20%, reducing production disruptions.

- Developed a training module for new operators, improving their efficiency and reducing onthejob errors.

- Identified and eliminated a bottleneck in the production process, increasing throughput by 12%.

Awards

- Received the Operator Excellence Award for consistently exceeding production targets and maintaining highquality standards.

- Recognized as Employee of the Month for exceptional performance in optimizing machine efficiency and reducing downtime.

- Awarded the Safety Hero designation for maintaining an impeccable safety record and promoting best practices.

- Received a Certificate of Excellence for successfully completing an advanced training program on cloth shrinking technology.

Certificates

- Textile Shrinking Machine Operator Certification

- Safety Compliance in Textile Manufacturing Certification

- OSHA Safety Certification

- First Aid/CPR Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Cloth Shrinking Machine Operator

- Highlight your experience and expertise in operating and maintaining cloth shrinking machines.

- Showcase your knowledge of fabric shrinking techniques and your ability to control fabric shrinkage and moisture content.

- Emphasize your troubleshooting and problem-solving skills, including your ability to resolve machine malfunctions quickly and efficiently.

- Demonstrate your commitment to quality control, ensuring that fabrics meet the desired shrinkage and quality standards.

Essential Experience Highlights for a Strong Cloth Shrinking Machine Operator Resume

- Operate and maintain cloth shrinking machines, ensuring optimal fabric shrinkage and quality control.

- Monitor and control steam chamber temperature, pressure, and humidity to achieve desired shrinkage results.

- Measure and adjust fabric moisture content to ensure uniform shrinkage and prevent fabric damage.

- Troubleshoot and resolve machine malfunctions, including mechanical, electrical, and steam-related issues.

- Monitor production processes, maintain records, and ensure compliance with quality standards.

- Handle and store fabrics safely, minimizing damage and ensuring proper inventory management.

- Adhere to safety protocols and maintain a clean and organized work environment.

Frequently Asked Questions (FAQ’s) For Cloth Shrinking Machine Operator

What is the primary role of a Cloth Shrinking Machine Operator?

The primary role of a Cloth Shrinking Machine Operator is to operate and maintain cloth shrinking machines, ensuring optimal fabric shrinkage and quality control.

What skills are required to become a successful Cloth Shrinking Machine Operator?

To become a successful Cloth Shrinking Machine Operator, you need proficiency in operating and maintaining cloth shrinking machines, knowledge of fabric shrinking techniques, and troubleshooting and problem-solving abilities.

What is the work environment like for a Cloth Shrinking Machine Operator?

Cloth Shrinking Machine Operators typically work in textile manufacturing plants or garment manufacturing companies. The work environment can be noisy due to the machinery, and may involve working with chemicals and steam.

What are the career prospects for a Cloth Shrinking Machine Operator?

With experience and additional training, Cloth Shrinking Machine Operators can advance to supervisory roles, such as Production Supervisor or Quality Control Manager.

What is the salary range for a Cloth Shrinking Machine Operator?

The salary range for a Cloth Shrinking Machine Operator can vary depending on experience, location, and company size. According to Indeed, the average salary for a Cloth Shrinking Machine Operator in the United States is $17.50 per hour.

What are the challenges faced by Cloth Shrinking Machine Operators?

Cloth Shrinking Machine Operators may face challenges such as working with delicate fabrics that require careful handling, ensuring consistent shrinkage results, and troubleshooting complex machine malfunctions.

What is the importance of quality control for Cloth Shrinking Machine Operators?

Quality control is crucial for Cloth Shrinking Machine Operators as it ensures that fabrics meet the desired shrinkage and quality standards, preventing defects and customer dissatisfaction.

How can Cloth Shrinking Machine Operators improve their skills?

Cloth Shrinking Machine Operators can improve their skills by staying updated on the latest industry techniques, attending training programs, and seeking mentorship from experienced professionals.