Are you a seasoned CNC Machine Setter (Computer Numerically Controlled Machine Setter) seeking a new career path? Discover our professionally built CNC Machine Setter (Computer Numerically Controlled Machine Setter) Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

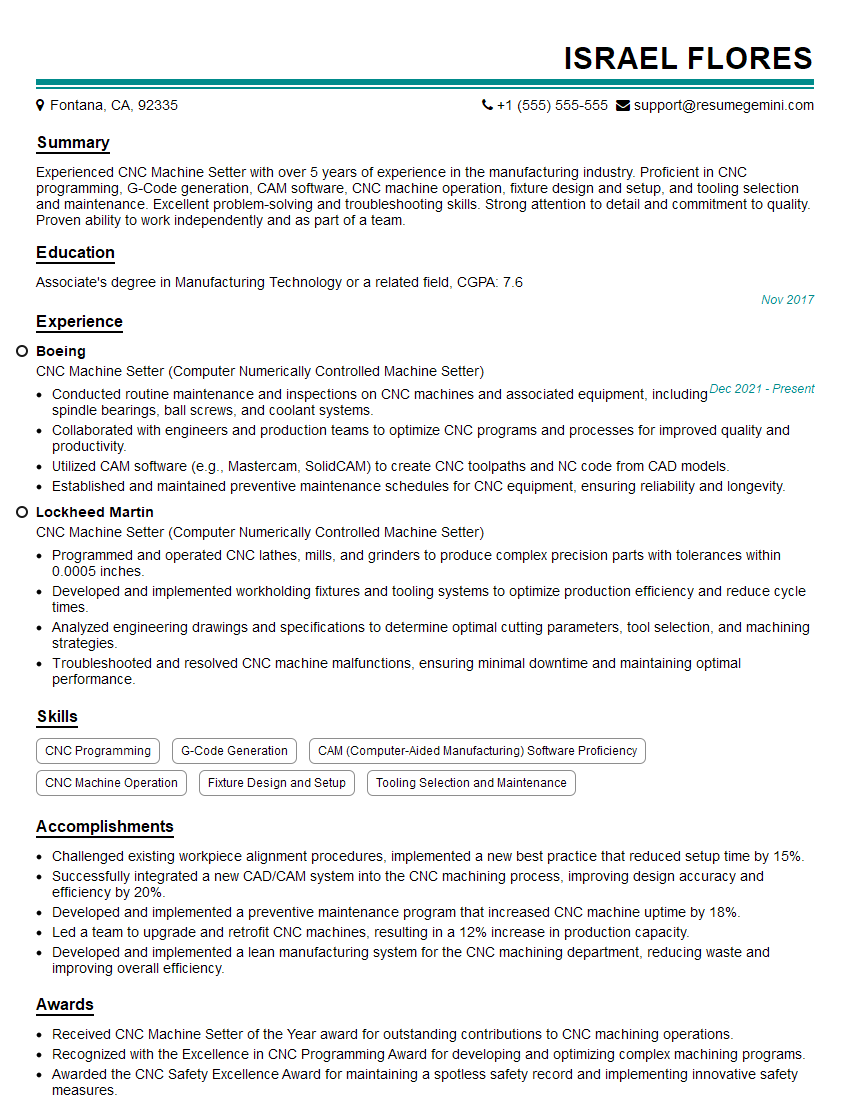

Israel Flores

CNC Machine Setter (Computer Numerically Controlled Machine Setter)

Summary

Experienced CNC Machine Setter with over 5 years of experience in the manufacturing industry. Proficient in CNC programming, G-Code generation, CAM software, CNC machine operation, fixture design and setup, and tooling selection and maintenance. Excellent problem-solving and troubleshooting skills. Strong attention to detail and commitment to quality. Proven ability to work independently and as part of a team.

Education

Associate’s degree in Manufacturing Technology or a related field

November 2017

Skills

- CNC Programming

- G-Code Generation

- CAM (Computer-Aided Manufacturing) Software Proficiency

- CNC Machine Operation

- Fixture Design and Setup

- Tooling Selection and Maintenance

Work Experience

CNC Machine Setter (Computer Numerically Controlled Machine Setter)

- Conducted routine maintenance and inspections on CNC machines and associated equipment, including spindle bearings, ball screws, and coolant systems.

- Collaborated with engineers and production teams to optimize CNC programs and processes for improved quality and productivity.

- Utilized CAM software (e.g., Mastercam, SolidCAM) to create CNC toolpaths and NC code from CAD models.

- Established and maintained preventive maintenance schedules for CNC equipment, ensuring reliability and longevity.

CNC Machine Setter (Computer Numerically Controlled Machine Setter)

- Programmed and operated CNC lathes, mills, and grinders to produce complex precision parts with tolerances within 0.0005 inches.

- Developed and implemented workholding fixtures and tooling systems to optimize production efficiency and reduce cycle times.

- Analyzed engineering drawings and specifications to determine optimal cutting parameters, tool selection, and machining strategies.

- Troubleshooted and resolved CNC machine malfunctions, ensuring minimal downtime and maintaining optimal performance.

Accomplishments

- Challenged existing workpiece alignment procedures, implemented a new best practice that reduced setup time by 15%.

- Successfully integrated a new CAD/CAM system into the CNC machining process, improving design accuracy and efficiency by 20%.

- Developed and implemented a preventive maintenance program that increased CNC machine uptime by 18%.

- Led a team to upgrade and retrofit CNC machines, resulting in a 12% increase in production capacity.

- Developed and implemented a lean manufacturing system for the CNC machining department, reducing waste and improving overall efficiency.

Awards

- Received CNC Machine Setter of the Year award for outstanding contributions to CNC machining operations.

- Recognized with the Excellence in CNC Programming Award for developing and optimizing complex machining programs.

- Awarded the CNC Safety Excellence Award for maintaining a spotless safety record and implementing innovative safety measures.

- Received the CNC Machine Maintenance Award for exceptional skills in troubleshooting and repairing CNC machines.

Certificates

- Certified CNC Machine Operator (CMMO)

- Certified Manufacturing Technologist (CMfgT)

- Precision Machining Certificate

- Lean Manufacturing Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For CNC Machine Setter (Computer Numerically Controlled Machine Setter)

- Highlight your skills and experience in CNC programming and G-Code generation.

- Demonstrate your knowledge of CAM software and its application in CNC machining.

- Showcase your ability to troubleshoot and resolve CNC machine problems.

- Emphasize your attention to detail and commitment to quality.

- Include examples of your work and accomplishments in your resume.

Essential Experience Highlights for a Strong CNC Machine Setter (Computer Numerically Controlled Machine Setter) Resume

- Set up and operate CNC machines according to blueprints and specifications.

- Write and edit CNC programs using G-Code and other programming languages.

- Inspect and maintain CNC machines and tooling to ensure optimal performance.

- Troubleshoot and resolve machine malfunctions and errors.

- Train and supervise junior CNC operators and apprentices.

- Follow safety protocols and maintain a clean and organized work environment.

- Stay up-to-date on the latest CNC technologies and best practices.

Frequently Asked Questions (FAQ’s) For CNC Machine Setter (Computer Numerically Controlled Machine Setter)

What are the primary responsibilities of a CNC Machine Setter?

The primary responsibilities of a CNC Machine Setter include setting up and operating CNC machines, writing and editing CNC programs, inspecting and maintaining CNC machines and tooling, troubleshooting and resolving machine malfunctions and errors, and training and supervising junior CNC operators and apprentices.

What skills are required to be a successful CNC Machine Setter?

To be a successful CNC Machine Setter, you need to have excellent CNC programming and G-Code generation skills, knowledge of CAM software and its application in CNC machining, and proficiency in troubleshooting and resolving CNC machine problems. Additionally, attention to detail, commitment to quality, and the ability to work independently and as part of a team are essential.

What are the different types of CNC machines that a CNC Machine Setter may work with?

CNC Machine Setters may work with various types of CNC machines, including CNC mills, CNC lathes, CNC routers, and CNC plasma cutters, depending on the industry and specific job requirements.

What industries employ CNC Machine Setters?

CNC Machine Setters are employed in various industries that utilize CNC machines, such as manufacturing, aerospace, automotive, and medical device manufacturing.

What is the job outlook for CNC Machine Setters?

The job outlook for CNC Machine Setters is expected to be good in the coming years due to the increasing demand for skilled machinists and the growing adoption of CNC technology in various industries.

What are the career advancement opportunities for CNC Machine Setters?

CNC Machine Setters can advance their careers by becoming CNC programmers, CNC supervisors, or manufacturing engineers. With additional education and experience, they may also move into management roles.