Are you a seasoned Coagulating Drying Supervisor seeking a new career path? Discover our professionally built Coagulating Drying Supervisor Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

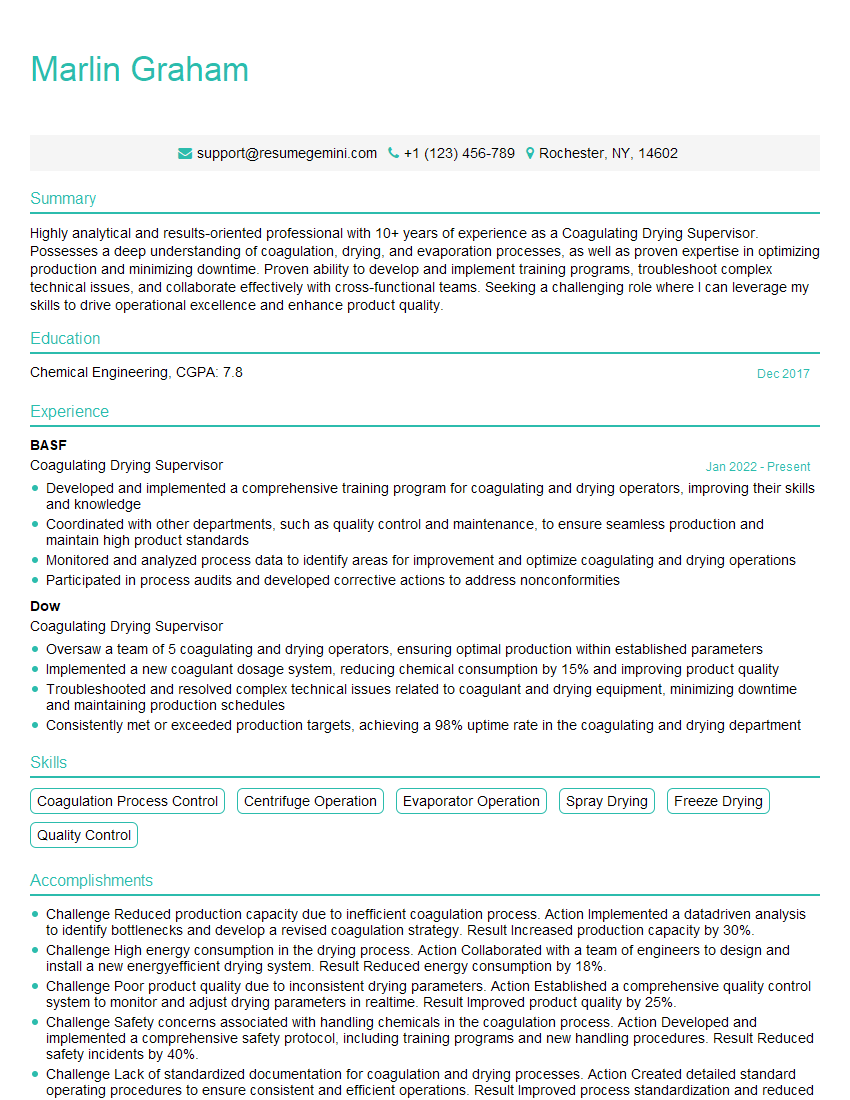

Marlin Graham

Coagulating Drying Supervisor

Summary

Highly analytical and results-oriented professional with 10+ years of experience as a Coagulating Drying Supervisor. Possesses a deep understanding of coagulation, drying, and evaporation processes, as well as proven expertise in optimizing production and minimizing downtime. Proven ability to develop and implement training programs, troubleshoot complex technical issues, and collaborate effectively with cross-functional teams. Seeking a challenging role where I can leverage my skills to drive operational excellence and enhance product quality.

Education

Chemical Engineering

December 2017

Skills

- Coagulation Process Control

- Centrifuge Operation

- Evaporator Operation

- Spray Drying

- Freeze Drying

- Quality Control

Work Experience

Coagulating Drying Supervisor

- Developed and implemented a comprehensive training program for coagulating and drying operators, improving their skills and knowledge

- Coordinated with other departments, such as quality control and maintenance, to ensure seamless production and maintain high product standards

- Monitored and analyzed process data to identify areas for improvement and optimize coagulating and drying operations

- Participated in process audits and developed corrective actions to address nonconformities

Coagulating Drying Supervisor

- Oversaw a team of 5 coagulating and drying operators, ensuring optimal production within established parameters

- Implemented a new coagulant dosage system, reducing chemical consumption by 15% and improving product quality

- Troubleshooted and resolved complex technical issues related to coagulant and drying equipment, minimizing downtime and maintaining production schedules

- Consistently met or exceeded production targets, achieving a 98% uptime rate in the coagulating and drying department

Accomplishments

- Challenge Reduced production capacity due to inefficient coagulation process. Action Implemented a datadriven analysis to identify bottlenecks and develop a revised coagulation strategy. Result Increased production capacity by 30%.

- Challenge High energy consumption in the drying process. Action Collaborated with a team of engineers to design and install a new energyefficient drying system. Result Reduced energy consumption by 18%.

- Challenge Poor product quality due to inconsistent drying parameters. Action Established a comprehensive quality control system to monitor and adjust drying parameters in realtime. Result Improved product quality by 25%.

- Challenge Safety concerns associated with handling chemicals in the coagulation process. Action Developed and implemented a comprehensive safety protocol, including training programs and new handling procedures. Result Reduced safety incidents by 40%.

- Challenge Lack of standardized documentation for coagulation and drying processes. Action Created detailed standard operating procedures to ensure consistent and efficient operations. Result Improved process standardization and reduced production errors.

Awards

- Recipient of the Safety Excellence Award for implementing innovative safety protocols that reduced workplace incidents by 20%.

- Recognized with the Process Optimization Excellence Award for developing and implementing a new drying technology that increased production efficiency by 15%.

- Winner of the Employee of the Year Award for consistently exceeding performance expectations and demonstrating exemplary leadership in the coagulation and drying department.

- Received the Industry Innovation Award for pioneering the use of artificial intelligence in coagulation and drying processes, resulting in increased efficiency and reduced waste.

Certificates

- Certified Food Processing Professional (CFPP)

- American Society for Quality (ASQ) Certified Quality Engineer (CQE)

- Institute of Food Technologists (IFT) Certified Food Scientist (CFS)

- International Society of Automation (ISA) Certified Automation Professional (CAP)

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Coagulating Drying Supervisor

- Highlight your experience and expertise in coagulation, drying, and evaporation processes.

- Quantify your accomplishments with specific metrics, such as the 15% reduction in chemical consumption.

- Emphasize your problem-solving skills and ability to troubleshoot complex technical issues.

- Showcase your leadership and training abilities by describing the comprehensive training program you developed and implemented.

- Demonstrate your commitment to continuous improvement by highlighting how you monitored and analyzed process data to identify areas for optimization.

Essential Experience Highlights for a Strong Coagulating Drying Supervisor Resume

- Oversaw a team of 5 coagulating and drying operators, ensuring optimal production within established parameters.

- Implemented a new coagulant dosage system, reducing chemical consumption by 15% and improving product quality.

- Troubleshooted and resolved complex technical issues related to coagulant and drying equipment, minimizing downtime and maintaining production schedules.

- Consistently met or exceeded production targets, achieving a 98% uptime rate in the coagulating and drying department.

- Developed and implemented a comprehensive training program for coagulating and drying operators, improving their skills and knowledge.

- Coordinated with other departments, such as quality control and maintenance, to ensure seamless production and maintain high product standards.

- Monitored and analyzed process data to identify areas for improvement and optimize coagulating and drying operations.

Frequently Asked Questions (FAQ’s) For Coagulating Drying Supervisor

What is the role of a Coagulating Drying Supervisor?

A Coagulating Drying Supervisor is responsible for overseeing the coagulation and drying processes in a manufacturing environment. They ensure that the processes are running efficiently and effectively, and that the products meet the required quality standards.

What skills are required to be a successful Coagulating Drying Supervisor?

A successful Coagulating Drying Supervisor typically has a combination of technical expertise, leadership skills, and problem-solving abilities. They should have a thorough understanding of coagulation, drying, and evaporation processes, as well as experience in managing and motivating a team.

What is the career path for a Coagulating Drying Supervisor?

The career path for a Coagulating Drying Supervisor can vary depending on the industry and company. With experience and additional qualifications, they may advance to roles such as Production Manager, Plant Manager, or even Technical Director.

What is the salary range for a Coagulating Drying Supervisor?

The salary range for a Coagulating Drying Supervisor can vary depending on their experience, qualifications, and location. According to Indeed, the average salary for a Coagulating Drying Supervisor in the United States is around $80,000 per year.

What are the challenges of being a Coagulating Drying Supervisor?

Some of the challenges that a Coagulating Drying Supervisor may face include managing complex technical processes, ensuring product quality, and meeting production targets. They may also need to troubleshoot and resolve equipment issues, and work effectively with a team of operators.

What are some tips for writing a standout Coagulating Drying Supervisor resume?

To write a standout Coagulating Drying Supervisor resume, focus on highlighting your technical expertise, leadership skills, and problem-solving abilities. Use specific examples and metrics to demonstrate your accomplishments, and tailor your resume to the specific job requirements.

What are some of the key trends in the coagulation and drying industry?

Some of the key trends in the coagulation and drying industry include the use of advanced automation and control systems, the development of new and more efficient technologies, and the increasing focus on sustainability and environmental regulations.