Are you a seasoned Coal Cutter seeking a new career path? Discover our professionally built Coal Cutter Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

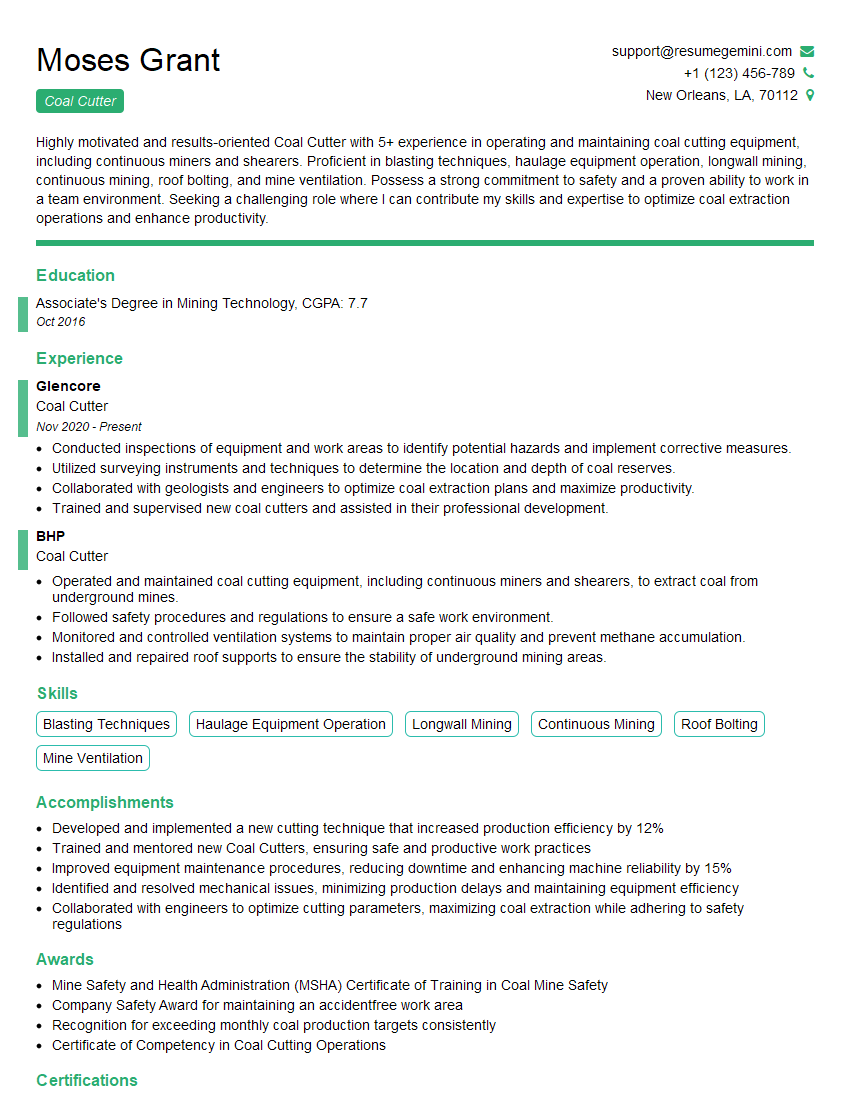

Moses Grant

Coal Cutter

Summary

Highly motivated and results-oriented Coal Cutter with 5+ experience in operating and maintaining coal cutting equipment, including continuous miners and shearers. Proficient in blasting techniques, haulage equipment operation, longwall mining, continuous mining, roof bolting, and mine ventilation. Possess a strong commitment to safety and a proven ability to work in a team environment. Seeking a challenging role where I can contribute my skills and expertise to optimize coal extraction operations and enhance productivity.

Education

Associate’s Degree in Mining Technology

October 2016

Skills

- Blasting Techniques

- Haulage Equipment Operation

- Longwall Mining

- Continuous Mining

- Roof Bolting

- Mine Ventilation

Work Experience

Coal Cutter

- Conducted inspections of equipment and work areas to identify potential hazards and implement corrective measures.

- Utilized surveying instruments and techniques to determine the location and depth of coal reserves.

- Collaborated with geologists and engineers to optimize coal extraction plans and maximize productivity.

- Trained and supervised new coal cutters and assisted in their professional development.

Coal Cutter

- Operated and maintained coal cutting equipment, including continuous miners and shearers, to extract coal from underground mines.

- Followed safety procedures and regulations to ensure a safe work environment.

- Monitored and controlled ventilation systems to maintain proper air quality and prevent methane accumulation.

- Installed and repaired roof supports to ensure the stability of underground mining areas.

Accomplishments

- Developed and implemented a new cutting technique that increased production efficiency by 12%

- Trained and mentored new Coal Cutters, ensuring safe and productive work practices

- Improved equipment maintenance procedures, reducing downtime and enhancing machine reliability by 15%

- Identified and resolved mechanical issues, minimizing production delays and maintaining equipment efficiency

- Collaborated with engineers to optimize cutting parameters, maximizing coal extraction while adhering to safety regulations

Awards

- Mine Safety and Health Administration (MSHA) Certificate of Training in Coal Mine Safety

- Company Safety Award for maintaining an accidentfree work area

- Recognition for exceeding monthly coal production targets consistently

- Certificate of Competency in Coal Cutting Operations

Certificates

- Certified Coal Miner

- First-Aid and CPR Certification

- Mine Safety and Health Administration (MSHA) Certification

- National Institute for Occupational Safety and Health (NIOSH) Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Coal Cutter

- Highlight your experience in operating and maintaining coal cutting equipment, including continuous miners and shearers.

- Emphasize your knowledge of blasting techniques, haulage equipment operation, longwall mining, continuous mining, roof bolting, and mine ventilation.

- Demonstrate your commitment to safety by mentioning your adherence to safety procedures and regulations.

- Showcase your ability to work in a team environment and collaborate with geologists and engineers.

Essential Experience Highlights for a Strong Coal Cutter Resume

- Operate and maintain coal cutting equipment, including continuous miners and shearers, to extract coal from underground mines.

- Follow safety procedures and regulations to ensure a safe work environment.

- Monitor and control ventilation systems to maintain proper air quality and prevent methane accumulation.

- Install and repair roof supports to ensure the stability of underground mining areas.

- Conduct inspections of equipment and work areas to identify potential hazards and implement corrective measures.

- Utilize surveying instruments and techniques to determine the location and depth of coal reserves.

- Collaborate with geologists and engineers to optimize coal extraction plans and maximize productivity.

Frequently Asked Questions (FAQ’s) For Coal Cutter

What are the key responsibilities of a Coal Cutter?

The key responsibilities of a Coal Cutter include operating and maintaining coal cutting equipment, following safety procedures, monitoring ventilation systems, installing and repairing roof supports, conducting inspections, utilizing surveying instruments, and collaborating with geologists and engineers.

What qualifications are required to become a Coal Cutter?

To become a Coal Cutter, you typically need an Associate’s Degree in Mining Technology or a related field, along with experience in operating and maintaining coal cutting equipment.

What are the career prospects for Coal Cutters?

Coal Cutters can advance to positions such as Mine Supervisor, Production Manager, or Safety Manager. With additional education and experience, they may also pursue roles in engineering, geology, or environmental management.

What are the challenges faced by Coal Cutters?

Coal Cutters face challenges such as working in hazardous underground environments, exposure to dust and noise, and the need to adhere to strict safety regulations.

What is the work schedule of a Coal Cutter?

Coal Cutters typically work shifts that can range from 8 to 12 hours, and they may work overtime or on weekends to meet production demands.

What are the safety precautions taken by Coal Cutters?

Coal Cutters follow strict safety procedures, including wearing protective gear, adhering to ventilation regulations, and undergoing regular safety training.