Are you a seasoned Coating and Embossing Unit Operator seeking a new career path? Discover our professionally built Coating and Embossing Unit Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

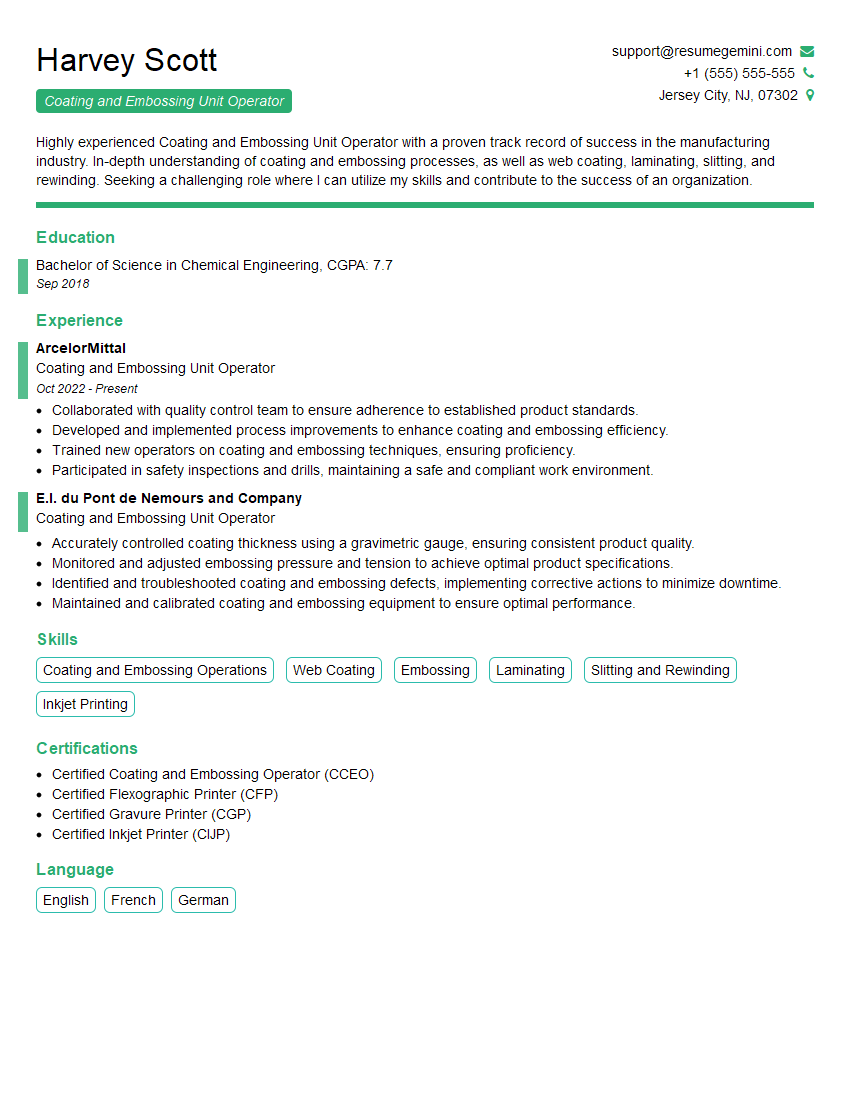

Harvey Scott

Coating and Embossing Unit Operator

Summary

Highly experienced Coating and Embossing Unit Operator with a proven track record of success in the manufacturing industry. In-depth understanding of coating and embossing processes, as well as web coating, laminating, slitting, and rewinding. Seeking a challenging role where I can utilize my skills and contribute to the success of an organization.

Education

Bachelor of Science in Chemical Engineering

September 2018

Skills

- Coating and Embossing Operations

- Web Coating

- Embossing

- Laminating

- Slitting and Rewinding

- Inkjet Printing

Work Experience

Coating and Embossing Unit Operator

- Collaborated with quality control team to ensure adherence to established product standards.

- Developed and implemented process improvements to enhance coating and embossing efficiency.

- Trained new operators on coating and embossing techniques, ensuring proficiency.

- Participated in safety inspections and drills, maintaining a safe and compliant work environment.

Coating and Embossing Unit Operator

- Accurately controlled coating thickness using a gravimetric gauge, ensuring consistent product quality.

- Monitored and adjusted embossing pressure and tension to achieve optimal product specifications.

- Identified and troubleshooted coating and embossing defects, implementing corrective actions to minimize downtime.

- Maintained and calibrated coating and embossing equipment to ensure optimal performance.

Certificates

- Certified Coating and Embossing Operator (CCEO)

- Certified Flexographic Printer (CFP)

- Certified Gravure Printer (CGP)

- Certified Inkjet Printer (CIJP)

Languages

- English

- French

- German

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Coating and Embossing Unit Operator

- Highlight your technical skills and experience in coating and embossing operations, emphasizing your expertise in specific processes.

- Quantify your accomplishments whenever possible, providing metrics that demonstrate the impact of your work on productivity or quality.

- Showcase your attention to detail and commitment to quality by mentioning any quality control or improvement initiatives you have been involved in.

- Emphasize your ability to work independently and as part of a team, highlighting your communication and interpersonal skills.

Essential Experience Highlights for a Strong Coating and Embossing Unit Operator Resume

- Operate and maintain coating and embossing equipment, ensuring optimal performance and product quality.

- Monitor and control process parameters, such as temperature, pressure, and speed, to achieve desired results.

- Inspect finished products for defects and ensure adherence to quality standards.

- Perform routine maintenance and troubleshooting on equipment to minimize downtime and maintain productivity.

- Collaborate with other team members in the production process, including material handling and shipping.

- Stay up-to-date on industry best practices and advancements in coating and embossing technologies.

- Adhere to all safety regulations and procedures to ensure a safe and healthy work environment.

Frequently Asked Questions (FAQ’s) For Coating and Embossing Unit Operator

What are the key skills required for a Coating and Embossing Unit Operator?

Coating and Embossing Unit Operators typically require a strong understanding of coating and embossing processes, web coating, laminating, slitting, and rewinding. They should possess excellent attention to detail, problem-solving skills, and the ability to work in a fast-paced production environment.

What industries employ Coating and Embossing Unit Operators?

Coating and Embossing Unit Operators are employed in a variety of industries, including manufacturing, packaging, and printing. They work in facilities that produce a wide range of products, such as coated papers, films, and textiles.

What is the career outlook for Coating and Embossing Unit Operators?

The career outlook for Coating and Embossing Unit Operators is positive. The increasing demand for coated and embossed products is expected to drive demand for skilled operators in this field.

What are the educational requirements for becoming a Coating and Embossing Unit Operator?

While formal education is not always required, most Coating and Embossing Unit Operators have a high school diploma or equivalent. Some employers may prefer candidates with a post-secondary degree in a related field, such as chemical engineering or manufacturing technology.

What are the salary expectations for Coating and Embossing Unit Operators?

Salary expectations for Coating and Embossing Unit Operators vary depending on experience, location, and employer. According to Indeed, the average salary for Coating and Embossing Unit Operators in the United States is around $25.00 per hour.

What are the working conditions for Coating and Embossing Unit Operators?

Coating and Embossing Unit Operators typically work in manufacturing facilities. They may be exposed to noise, fumes, and chemicals. They may also be required to work overtime or on weekends to meet production demands.

What are the advancement opportunities for Coating and Embossing Unit Operators?

Coating and Embossing Unit Operators may advance to supervisory or management positions with experience. They may also specialize in a particular area of coating or embossing, such as quality control or research and development.