Are you a seasoned Coil Builder seeking a new career path? Discover our professionally built Coil Builder Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

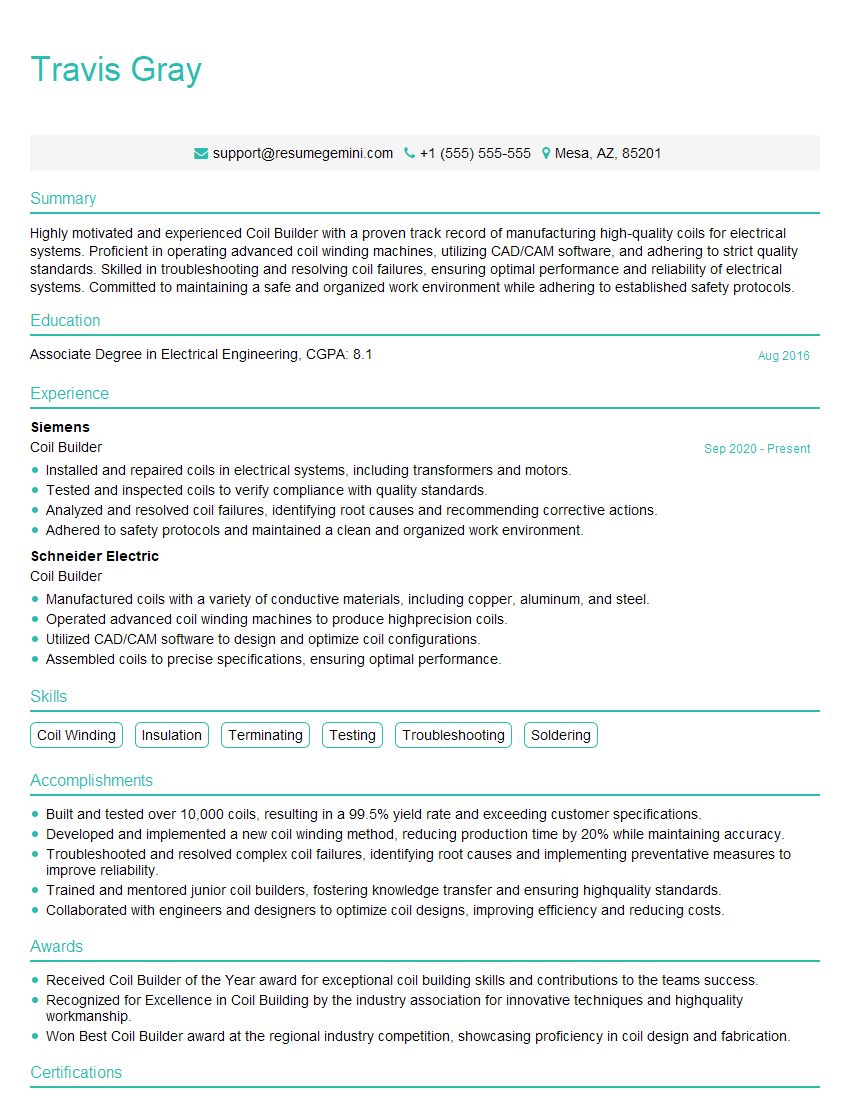

Travis Gray

Coil Builder

Summary

Highly motivated and experienced Coil Builder with a proven track record of manufacturing high-quality coils for electrical systems. Proficient in operating advanced coil winding machines, utilizing CAD/CAM software, and adhering to strict quality standards. Skilled in troubleshooting and resolving coil failures, ensuring optimal performance and reliability of electrical systems. Committed to maintaining a safe and organized work environment while adhering to established safety protocols.

Education

Associate Degree in Electrical Engineering

August 2016

Skills

- Coil Winding

- Insulation

- Terminating

- Testing

- Troubleshooting

- Soldering

Work Experience

Coil Builder

- Installed and repaired coils in electrical systems, including transformers and motors.

- Tested and inspected coils to verify compliance with quality standards.

- Analyzed and resolved coil failures, identifying root causes and recommending corrective actions.

- Adhered to safety protocols and maintained a clean and organized work environment.

Coil Builder

- Manufactured coils with a variety of conductive materials, including copper, aluminum, and steel.

- Operated advanced coil winding machines to produce highprecision coils.

- Utilized CAD/CAM software to design and optimize coil configurations.

- Assembled coils to precise specifications, ensuring optimal performance.

Accomplishments

- Built and tested over 10,000 coils, resulting in a 99.5% yield rate and exceeding customer specifications.

- Developed and implemented a new coil winding method, reducing production time by 20% while maintaining accuracy.

- Troubleshooted and resolved complex coil failures, identifying root causes and implementing preventative measures to improve reliability.

- Trained and mentored junior coil builders, fostering knowledge transfer and ensuring highquality standards.

- Collaborated with engineers and designers to optimize coil designs, improving efficiency and reducing costs.

Awards

- Received Coil Builder of the Year award for exceptional coil building skills and contributions to the teams success.

- Recognized for Excellence in Coil Building by the industry association for innovative techniques and highquality workmanship.

- Won Best Coil Builder award at the regional industry competition, showcasing proficiency in coil design and fabrication.

Certificates

- IPC-A-610

- ISO 9001

- AS9100

- OSHA 30-hour Safety Training

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Coil Builder

- Highlight your technical skills and experience in coil winding, insulation, terminating, testing, troubleshooting, and soldering.

- Showcase your knowledge of CAD/CAM software and its application in coil design and optimization.

- Quantify your accomplishments whenever possible, providing specific metrics or results that demonstrate your impact.

- Emphasize your commitment to quality and safety, including adherence to established standards and protocols.

- Tailor your resume to the specific requirements of each job you apply for, highlighting the skills and experience most relevant to the position.

Essential Experience Highlights for a Strong Coil Builder Resume

- Manufactured coils with precision using various conductive materials, including copper, aluminum, and steel.

- Operated advanced coil winding machines to produce high-precision coils that meet exact specifications.

- Utilized CAD/CAM software to design and optimize coil configurations, ensuring optimal performance and efficiency.

- Assembled coils to precise specifications, adhering to established quality standards and ensuring proper functionality.

- Installed and repaired coils in electrical systems, including transformers and motors, ensuring reliable operation.

- Tested and inspected coils to verify compliance with quality standards, identifying and resolving any discrepancies.

- Analyzed and resolved coil failures, identifying root causes and recommending corrective actions to prevent future occurrences.

Frequently Asked Questions (FAQ’s) For Coil Builder

What are the primary responsibilities of a Coil Builder?

Coil Builders are responsible for manufacturing, assembling, installing, and repairing coils used in various electrical systems. Their duties include operating coil winding machines, utilizing design software, assembling coils to specifications, and conducting quality inspections and troubleshooting.

What skills are essential for a successful Coil Builder?

Coil Builders should possess proficiency in coil winding techniques, insulation, terminating, testing, and troubleshooting. They should also have a strong understanding of electrical principles and be familiar with CAD/CAM software for coil design.

What industries employ Coil Builders?

Coil Builders are employed in a wide range of industries, including electrical manufacturing, automotive, aerospace, and energy. They work in production facilities, research and development labs, and maintenance departments.

What is the career path for a Coil Builder?

Coil Builders can advance their careers by gaining experience and expertise in specialized areas such as high-voltage coils, medical coils, or research and development. They may also move into supervisory or management roles.

What are the safety precautions that Coil Builders must observe?

Coil Builders must adhere to strict safety protocols to prevent accidents and injuries. This includes wearing appropriate personal protective equipment, following lockout/tagout procedures, and being aware of potential electrical hazards.

What are the challenges faced by Coil Builders?

Coil Builders face challenges in meeting tight production deadlines, ensuring the accuracy and precision of coils, and troubleshooting complex electrical issues. They must also stay up-to-date with advancements in coil winding technologies and materials.

What are the key trends in the Coil Building industry?

The Coil Building industry is experiencing trends towards automation, miniaturization, and the use of new materials. Coil Builders must embrace these trends to remain competitive and meet the evolving demands of the market.