Are you a seasoned Coil Taper seeking a new career path? Discover our professionally built Coil Taper Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

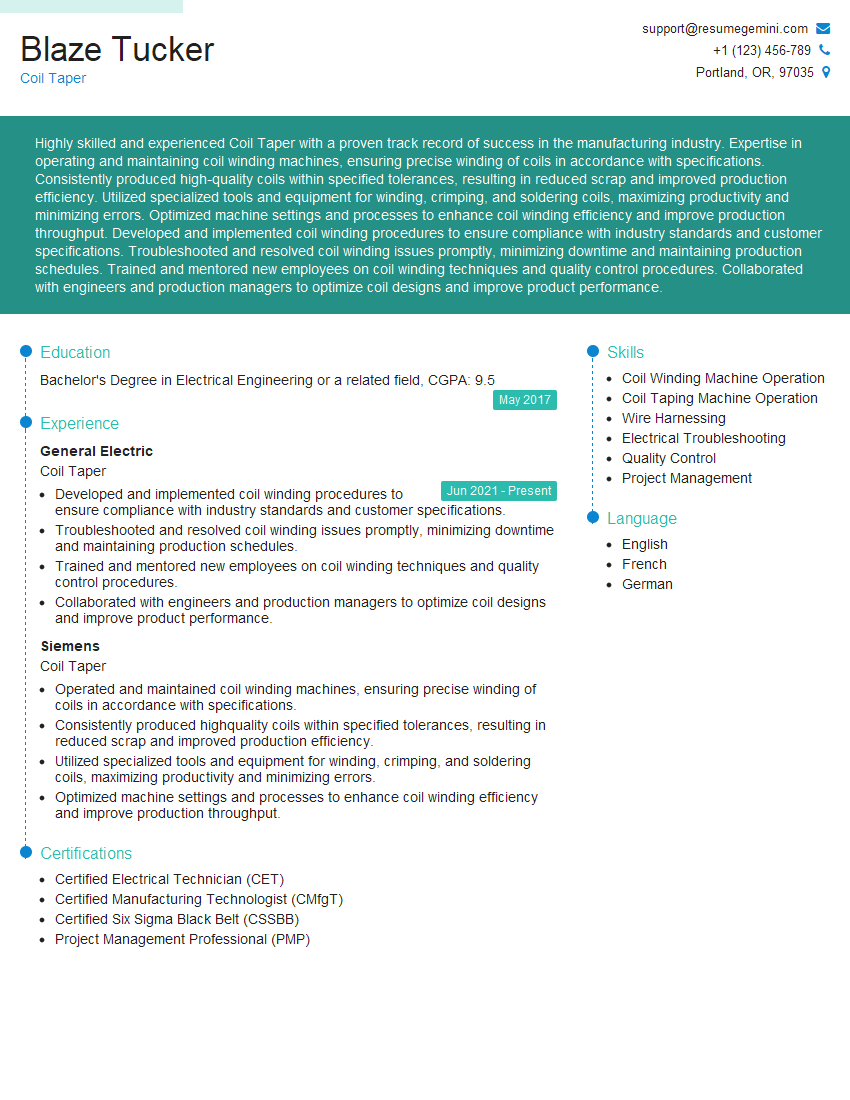

Blaze Tucker

Coil Taper

Summary

Highly skilled and experienced Coil Taper with a proven track record of success in the manufacturing industry. Expertise in operating and maintaining coil winding machines, ensuring precise winding of coils in accordance with specifications. Consistently produced high-quality coils within specified tolerances, resulting in reduced scrap and improved production efficiency. Utilized specialized tools and equipment for winding, crimping, and soldering coils, maximizing productivity and minimizing errors. Optimized machine settings and processes to enhance coil winding efficiency and improve production throughput. Developed and implemented coil winding procedures to ensure compliance with industry standards and customer specifications. Troubleshooted and resolved coil winding issues promptly, minimizing downtime and maintaining production schedules. Trained and mentored new employees on coil winding techniques and quality control procedures. Collaborated with engineers and production managers to optimize coil designs and improve product performance.

Education

Bachelor’s Degree in Electrical Engineering or a related field

May 2017

Skills

- Coil Winding Machine Operation

- Coil Taping Machine Operation

- Wire Harnessing

- Electrical Troubleshooting

- Quality Control

- Project Management

Work Experience

Coil Taper

- Developed and implemented coil winding procedures to ensure compliance with industry standards and customer specifications.

- Troubleshooted and resolved coil winding issues promptly, minimizing downtime and maintaining production schedules.

- Trained and mentored new employees on coil winding techniques and quality control procedures.

- Collaborated with engineers and production managers to optimize coil designs and improve product performance.

Coil Taper

- Operated and maintained coil winding machines, ensuring precise winding of coils in accordance with specifications.

- Consistently produced highquality coils within specified tolerances, resulting in reduced scrap and improved production efficiency.

- Utilized specialized tools and equipment for winding, crimping, and soldering coils, maximizing productivity and minimizing errors.

- Optimized machine settings and processes to enhance coil winding efficiency and improve production throughput.

Certificates

- Certified Electrical Technician (CET)

- Certified Manufacturing Technologist (CMfgT)

- Certified Six Sigma Black Belt (CSSBB)

- Project Management Professional (PMP)

Languages

- English

- French

- German

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Coil Taper

- Highlight your experience and expertise in coil winding machine operation and maintenance.

- Quantify your accomplishments with specific metrics, such as percentages of reduced scrap and improved production efficiency.

- Showcase your knowledge of specialized tools and equipment used in coil winding.

- Emphasize your ability to optimize machine settings and processes to enhance productivity.

- Demonstrate your commitment to quality control and adherence to industry standards.

Essential Experience Highlights for a Strong Coil Taper Resume

- Operate and maintain coil winding machines to ensure precise winding of coils in accordance with specifications.

- Consistently produce high-quality coils within specified tolerances, resulting in reduced scrap and improved production efficiency.

- Utilize specialized tools and equipment for winding, crimping, and soldering coils, maximizing productivity and minimizing errors.

- Optimize machine settings and processes to enhance coil winding efficiency and improve production throughput.

- Develop and implement coil winding procedures to ensure compliance with industry standards and customer specifications.

- Troubleshoot and resolve coil winding issues promptly, minimizing downtime and maintaining production schedules.

- Train and mentor new employees on coil winding techniques and quality control procedures.

- Collaborate with engineers and production managers to optimize coil designs and improve product performance.

Frequently Asked Questions (FAQ’s) For Coil Taper

What are the key responsibilities of a Coil Taper?

The key responsibilities of a Coil Taper include operating and maintaining coil winding machines, producing high-quality coils within specified tolerances, utilizing specialized tools and equipment, optimizing machine settings and processes, developing and implementing coil winding procedures, troubleshooting and resolving coil winding issues, and training and mentoring new employees.

What qualifications are required to become a Coil Taper?

To become a Coil Taper, you typically need a high school diploma or equivalent, as well as experience in operating coil winding machines. Some employers may prefer candidates with a bachelor’s degree in electrical engineering or a related field.

What are the career prospects for Coil Tapers?

Coil Tapers can advance their careers by becoming supervisors or managers in the manufacturing industry. They can also specialize in a particular type of coil winding, such as transformer winding or motor winding.

What is the work environment of a Coil Taper?

Coil Tapers typically work in manufacturing facilities. They may work in a variety of environments, including clean rooms and workshops. They may also work with a variety of chemicals and solvents.

What are the safety precautions that Coil Tapers should take?

Coil Tapers should wear appropriate safety gear, such as gloves, safety glasses, and earplugs. They should also be aware of the potential hazards of working with electricity and chemicals.

What are the challenges that Coil Tapers face?

Coil Tapers may face challenges such as working with tight tolerances, meeting production deadlines, and working in a variety of environments.

What are the rewards of being a Coil Taper?

Coil Tapers can enjoy the rewards of a stable career in the manufacturing industry. They can also take pride in knowing that they are contributing to the production of high-quality products.

What is the average salary of a Coil Taper?

The average salary of a Coil Taper can vary depending on their experience, location, and employer. According to Salary.com, the average salary for Coil Tapers in the United States is $25.62 per hour.