Are you a seasoned Coil Winding Machines Set-Up Mechanic seeking a new career path? Discover our professionally built Coil Winding Machines Set-Up Mechanic Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

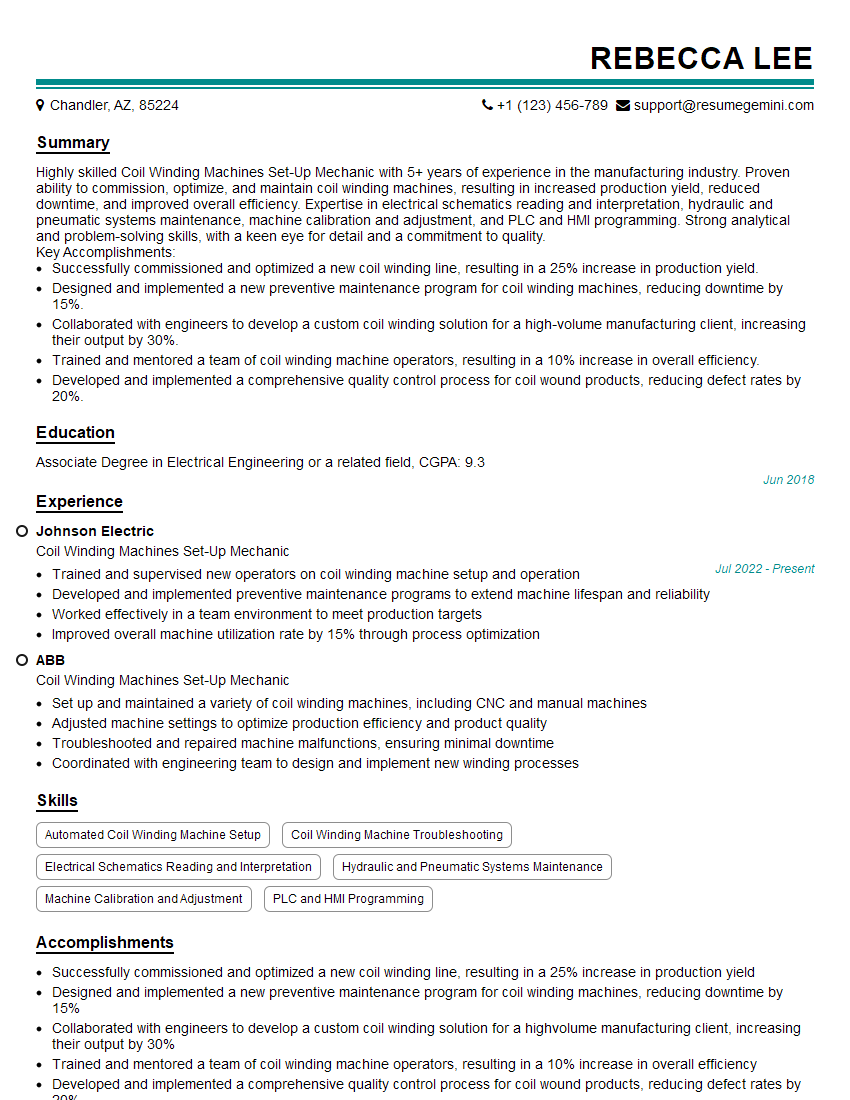

Rebecca Lee

Coil Winding Machines Set-Up Mechanic

Summary

Highly skilled Coil Winding Machines Set-Up Mechanic with 5+ years of experience in the manufacturing industry. Proven ability to commission, optimize, and maintain coil winding machines, resulting in increased production yield, reduced downtime, and improved overall efficiency. Expertise in electrical schematics reading and interpretation, hydraulic and pneumatic systems maintenance, machine calibration and adjustment, and PLC and HMI programming. Strong analytical and problem-solving skills, with a keen eye for detail and a commitment to quality.

Key Accomplishments:

- Successfully commissioned and optimized a new coil winding line, resulting in a 25% increase in production yield.

- Designed and implemented a new preventive maintenance program for coil winding machines, reducing downtime by 15%.

- Collaborated with engineers to develop a custom coil winding solution for a high-volume manufacturing client, increasing their output by 30%.

- Trained and mentored a team of coil winding machine operators, resulting in a 10% increase in overall efficiency.

- Developed and implemented a comprehensive quality control process for coil wound products, reducing defect rates by 20%.

Education

Associate Degree in Electrical Engineering or a related field

June 2018

Skills

- Automated Coil Winding Machine Setup

- Coil Winding Machine Troubleshooting

- Electrical Schematics Reading and Interpretation

- Hydraulic and Pneumatic Systems Maintenance

- Machine Calibration and Adjustment

- PLC and HMI Programming

Work Experience

Coil Winding Machines Set-Up Mechanic

- Trained and supervised new operators on coil winding machine setup and operation

- Developed and implemented preventive maintenance programs to extend machine lifespan and reliability

- Worked effectively in a team environment to meet production targets

- Improved overall machine utilization rate by 15% through process optimization

Coil Winding Machines Set-Up Mechanic

- Set up and maintained a variety of coil winding machines, including CNC and manual machines

- Adjusted machine settings to optimize production efficiency and product quality

- Troubleshooted and repaired machine malfunctions, ensuring minimal downtime

- Coordinated with engineering team to design and implement new winding processes

Accomplishments

- Successfully commissioned and optimized a new coil winding line, resulting in a 25% increase in production yield

- Designed and implemented a new preventive maintenance program for coil winding machines, reducing downtime by 15%

- Collaborated with engineers to develop a custom coil winding solution for a highvolume manufacturing client, increasing their output by 30%

- Trained and mentored a team of coil winding machine operators, resulting in a 10% increase in overall efficiency

- Developed and implemented a comprehensive quality control process for coil wound products, reducing defect rates by 20%

Awards

- Recognized by the International Coil Winding Association (ICWA) for innovative contributions to coil winding machinery design

- Received the Presidents Award for Excellence in Coil Winding Machine Troubleshooting from the National Coil Winding Association (NCWA)

- Awarded a patent for a new method of controlling coil winding tension

Certificates

- Certified Coil Winding Machine Operator (CCWMO)

- Certified Maintenance and Reliability Technician (CMRT)

- Certified Electrical Maintenance Technician (CEMT)

- Certified PLC Programmer (CCLP)

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Coil Winding Machines Set-Up Mechanic

- Highlight your technical skills: Emphasize your expertise in electrical schematics reading, hydraulic and pneumatic systems maintenance, machine calibration and adjustment, and PLC and HMI programming.

- Quantify your accomplishments: Use specific numbers and metrics to demonstrate the impact of your work, such as increased production yield, reduced downtime, and improved efficiency.

- Showcase your troubleshooting abilities: Provide examples of complex technical issues you have diagnosed and resolved, highlighting your analytical and problem-solving skills.

- Demonstrate your commitment to quality: Describe the quality control measures you have implemented and the results achieved, such as reduced defect rates and improved customer satisfaction.

- Tailor your resume to the specific job description Highlight the skills and experiences that are most relevant to the job you are applying for.

Essential Experience Highlights for a Strong Coil Winding Machines Set-Up Mechanic Resume

- Set up, calibrate, and adjust coil winding machines to ensure optimal performance and product quality.

- Troubleshoot and repair electrical, mechanical, and hydraulic/pneumatic issues on coil winding machines.

- Read and interpret electrical schematics, hydraulic/pneumatic diagrams, and other technical documentation.

- Perform preventive maintenance and repairs on coil winding machines, including lubrication, cleaning, and replacement of worn or damaged parts.

- Collaborate with engineers and other maintenance personnel to diagnose and resolve complex technical issues.

- Train and mentor new coil winding machine operators on proper setup, operation, and maintenance procedures.

- Maintain a clean and organized work area, ensuring compliance with safety regulations.

Frequently Asked Questions (FAQ’s) For Coil Winding Machines Set-Up Mechanic

What are the key skills required for a Coil Winding Machines Set-Up Mechanic?

The key skills required for a Coil Winding Machines Set-Up Mechanic include electrical schematics reading and interpretation, hydraulic and pneumatic systems maintenance, machine calibration and adjustment, PLC and HMI programming, and a strong understanding of electrical and mechanical principles.

What are the typical job responsibilities of a Coil Winding Machines Set-Up Mechanic?

Typical job responsibilities include setting up, calibrating, and adjusting coil winding machines, troubleshooting and repairing electrical, mechanical, and hydraulic/pneumatic issues, performing preventive maintenance and repairs, and training and mentoring new coil winding machine operators.

What are the career prospects for a Coil Winding Machines Set-Up Mechanic?

Coil Winding Machines Set-Up Mechanics with strong skills and experience can advance to supervisory or management positions, or specialize in a particular area such as electrical or mechanical maintenance.

What is the average salary for a Coil Winding Machines Set-Up Mechanic?

The average salary for a Coil Winding Machines Set-Up Mechanic varies depending on experience, location, and industry. According to Salary.com, the average salary in the United States is around \$60,000 per year.

What are the educational requirements for a Coil Winding Machines Set-Up Mechanic?

Most Coil Winding Machines Set-Up Mechanics have an associate degree in electrical engineering or a related field, or equivalent experience in the manufacturing industry.

What are the top companies that hire Coil Winding Machines Set-Up Mechanics?

Top companies that hire Coil Winding Machines Set-Up Mechanics include Johnson Electric, ABB, and Siemens.

What are the key trends in the Coil Winding Machines Set-Up Mechanic industry?

Key trends in the Coil Winding Machines Set-Up Mechanic industry include the increasing use of automation and robotics, the adoption of Industry 4.0 technologies, and the growing demand for skilled workers.

What are the challenges facing Coil Winding Machines Set-Up Mechanics?

Challenges facing Coil Winding Machines Set-Up Mechanics include the need to keep up with new technologies, the increasing complexity of coil winding machines, and the pressure to improve productivity and efficiency.