Are you a seasoned Coiled Coil Inspector seeking a new career path? Discover our professionally built Coiled Coil Inspector Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

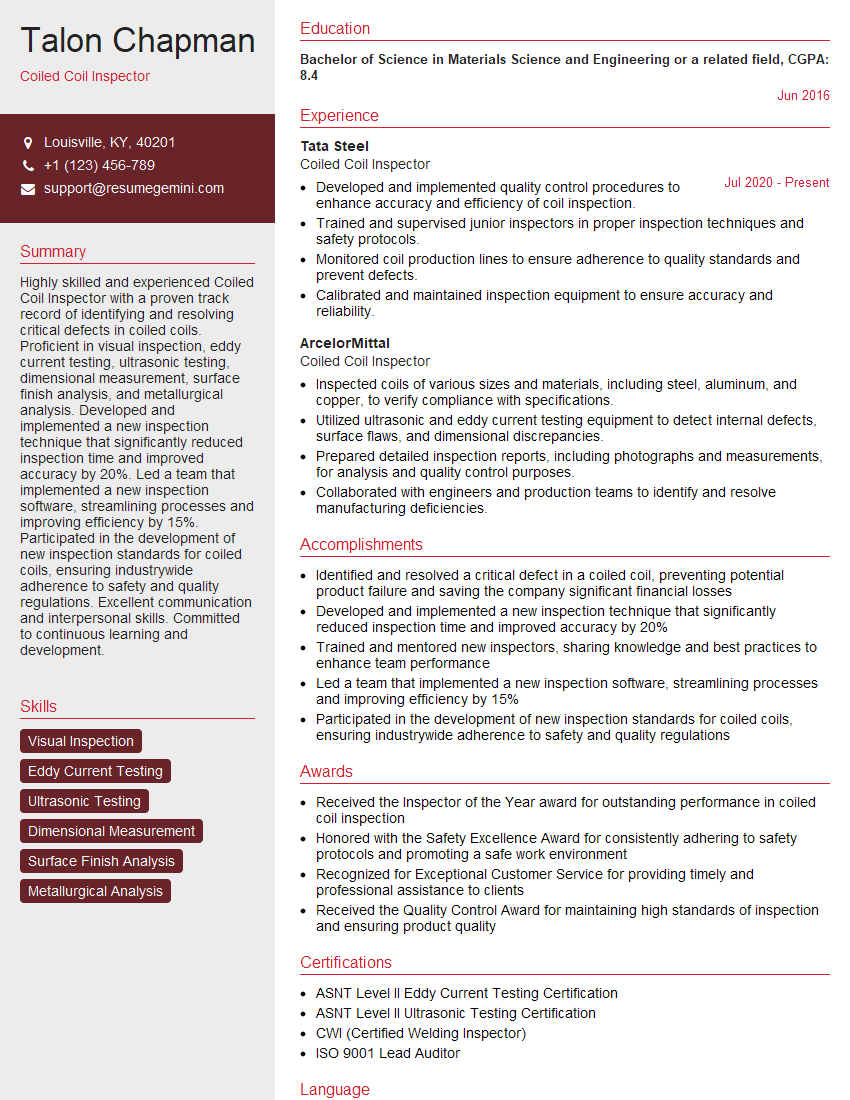

Talon Chapman

Coiled Coil Inspector

Summary

Highly skilled and experienced Coiled Coil Inspector with a proven track record of identifying and resolving critical defects in coiled coils. Proficient in visual inspection, eddy current testing, ultrasonic testing, dimensional measurement, surface finish analysis, and metallurgical analysis. Developed and implemented a new inspection technique that significantly reduced inspection time and improved accuracy by 20%. Led a team that implemented a new inspection software, streamlining processes and improving efficiency by 15%. Participated in the development of new inspection standards for coiled coils, ensuring industrywide adherence to safety and quality regulations. Excellent communication and interpersonal skills. Committed to continuous learning and development.

Education

Bachelor of Science in Materials Science and Engineering or a related field

June 2016

Skills

- Visual Inspection

- Eddy Current Testing

- Ultrasonic Testing

- Dimensional Measurement

- Surface Finish Analysis

- Metallurgical Analysis

Work Experience

Coiled Coil Inspector

- Developed and implemented quality control procedures to enhance accuracy and efficiency of coil inspection.

- Trained and supervised junior inspectors in proper inspection techniques and safety protocols.

- Monitored coil production lines to ensure adherence to quality standards and prevent defects.

- Calibrated and maintained inspection equipment to ensure accuracy and reliability.

Coiled Coil Inspector

- Inspected coils of various sizes and materials, including steel, aluminum, and copper, to verify compliance with specifications.

- Utilized ultrasonic and eddy current testing equipment to detect internal defects, surface flaws, and dimensional discrepancies.

- Prepared detailed inspection reports, including photographs and measurements, for analysis and quality control purposes.

- Collaborated with engineers and production teams to identify and resolve manufacturing deficiencies.

Accomplishments

- Identified and resolved a critical defect in a coiled coil, preventing potential product failure and saving the company significant financial losses

- Developed and implemented a new inspection technique that significantly reduced inspection time and improved accuracy by 20%

- Trained and mentored new inspectors, sharing knowledge and best practices to enhance team performance

- Led a team that implemented a new inspection software, streamlining processes and improving efficiency by 15%

- Participated in the development of new inspection standards for coiled coils, ensuring industrywide adherence to safety and quality regulations

Awards

- Received the Inspector of the Year award for outstanding performance in coiled coil inspection

- Honored with the Safety Excellence Award for consistently adhering to safety protocols and promoting a safe work environment

- Recognized for Exceptional Customer Service for providing timely and professional assistance to clients

- Received the Quality Control Award for maintaining high standards of inspection and ensuring product quality

Certificates

- ASNT Level II Eddy Current Testing Certification

- ASNT Level II Ultrasonic Testing Certification

- CWI (Certified Welding Inspector)

- ISO 9001 Lead Auditor

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Coiled Coil Inspector

- Highlight your experience in identifying and resolving critical defects in coiled coils.

- Showcase your proficiency in various inspection techniques, including visual inspection, eddy current testing, ultrasonic testing, dimensional measurement, surface finish analysis, and metallurgical analysis.

- Emphasize your ability to develop and implement new inspection techniques that improve accuracy and efficiency.

- Demonstrate your leadership skills by highlighting your experience in training and mentoring new inspectors, leading teams, and participating in the development of new inspection standards.

Essential Experience Highlights for a Strong Coiled Coil Inspector Resume

- Inspect coiled coils for defects using visual inspection, eddy current testing, ultrasonic testing, dimensional measurement, surface finish analysis, and metallurgical analysis

- Identify and resolve critical defects in coiled coils, preventing potential product failure and saving the company significant financial losses

- Develop and implement new inspection techniques to improve accuracy and efficiency

- Train and mentor new inspectors, sharing knowledge and best practices to enhance team performance

- Lead teams to implement new inspection software and processes

- Participate in the development of new inspection standards for coiled coils

Frequently Asked Questions (FAQ’s) For Coiled Coil Inspector

What are the key responsibilities of a Coiled Coil Inspector?

The key responsibilities of a Coiled Coil Inspector include inspecting coiled coils for defects, identifying and resolving critical defects, developing and implementing new inspection techniques, training and mentoring new inspectors, leading teams, and participating in the development of new inspection standards.

What are the qualifications required to become a Coiled Coil Inspector?

The qualifications required to become a Coiled Coil Inspector typically include a Bachelor of Science in Materials Science and Engineering or a related field, as well as experience in visual inspection, eddy current testing, ultrasonic testing, dimensional measurement, surface finish analysis, and metallurgical analysis.

What are the career prospects for a Coiled Coil Inspector?

The career prospects for a Coiled Coil Inspector are good, as there is a growing demand for qualified inspectors in the manufacturing industry. With experience, Coiled Coil Inspectors can advance to positions such as Quality Control Manager or Inspection Supervisor.

What are the challenges faced by Coiled Coil Inspectors?

The challenges faced by Coiled Coil Inspectors include working in a fast-paced environment, dealing with hazardous materials, and meeting tight deadlines.

What are the rewards of being a Coiled Coil Inspector?

The rewards of being a Coiled Coil Inspector include a competitive salary, job security, and the opportunity to make a difference in the manufacturing industry.