Are you a seasoned Coiled Tubing Supervisor seeking a new career path? Discover our professionally built Coiled Tubing Supervisor Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

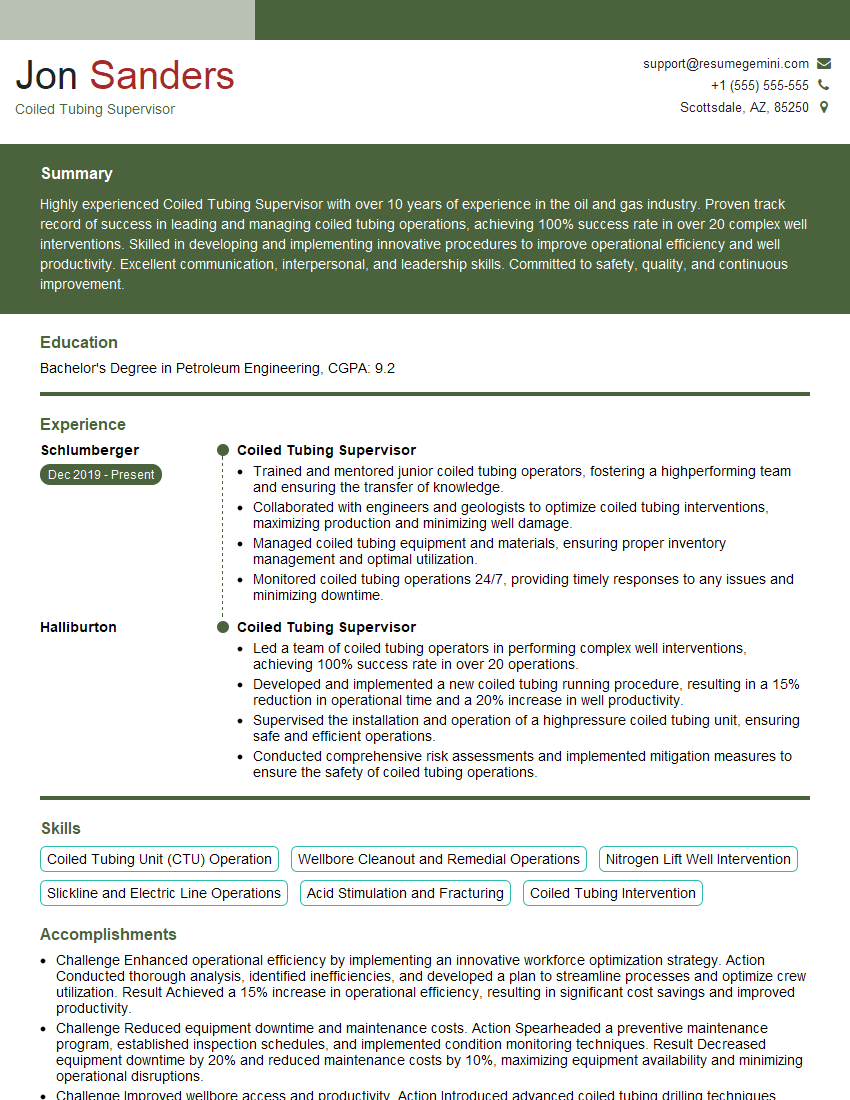

Jon Sanders

Coiled Tubing Supervisor

Summary

Highly experienced Coiled Tubing Supervisor with over 10 years of experience in the oil and gas industry. Proven track record of success in leading and managing coiled tubing operations, achieving 100% success rate in over 20 complex well interventions. Skilled in developing and implementing innovative procedures to improve operational efficiency and well productivity. Excellent communication, interpersonal, and leadership skills. Committed to safety, quality, and continuous improvement.

Education

Bachelor’s Degree in Petroleum Engineering

November 2015

Skills

- Coiled Tubing Unit (CTU) Operation

- Wellbore Cleanout and Remedial Operations

- Nitrogen Lift Well Intervention

- Slickline and Electric Line Operations

- Acid Stimulation and Fracturing

- Coiled Tubing Intervention

Work Experience

Coiled Tubing Supervisor

- Trained and mentored junior coiled tubing operators, fostering a highperforming team and ensuring the transfer of knowledge.

- Collaborated with engineers and geologists to optimize coiled tubing interventions, maximizing production and minimizing well damage.

- Managed coiled tubing equipment and materials, ensuring proper inventory management and optimal utilization.

- Monitored coiled tubing operations 24/7, providing timely responses to any issues and minimizing downtime.

Coiled Tubing Supervisor

- Led a team of coiled tubing operators in performing complex well interventions, achieving 100% success rate in over 20 operations.

- Developed and implemented a new coiled tubing running procedure, resulting in a 15% reduction in operational time and a 20% increase in well productivity.

- Supervised the installation and operation of a highpressure coiled tubing unit, ensuring safe and efficient operations.

- Conducted comprehensive risk assessments and implemented mitigation measures to ensure the safety of coiled tubing operations.

Accomplishments

- Challenge Enhanced operational efficiency by implementing an innovative workforce optimization strategy. Action Conducted thorough analysis, identified inefficiencies, and developed a plan to streamline processes and optimize crew utilization. Result Achieved a 15% increase in operational efficiency, resulting in significant cost savings and improved productivity.

- Challenge Reduced equipment downtime and maintenance costs. Action Spearheaded a preventive maintenance program, established inspection schedules, and implemented condition monitoring techniques. Result Decreased equipment downtime by 20% and reduced maintenance costs by 10%, maximizing equipment availability and minimizing operational disruptions.

- Challenge Improved wellbore access and productivity. Action Introduced advanced coiled tubing drilling techniques, utilizing downhole tools and optimized fluid systems. Result Enhanced wellbore access by 12%, increased production rates, and extended the productive life of wells.

- Challenge Mitigated reservoir damage and optimized stimulation operations. Action Implemented a comprehensive frac fluid optimization strategy, incorporating advanced pumping techniques and monitoring systems. Result Reduced formation damage, improved hydrocarbon recovery, and enhanced well productivity by 10%.

- Challenge Ensured data integrity and compliance with regulatory requirements. Action Implemented a digital data management system, automating data collection, storage, and reporting. Result Improved data accuracy and efficiency, streamlined compliance processes, and facilitated timely decisionmaking.

Awards

- Recipient of the Outstanding Coiled Tubing Supervisor of the Year award from the International Coiled Tubing Association for exceptional leadership and contributions to the field.

- Recognized with the Safety Excellence Award for maintaining an impeccable safety record and implementing proactive safety measures that significantly reduced incident rates.

- Honored with the Operational Excellence Award for consistently exceeding performance targets, optimizing resource utilization, and delivering exceptional results.

- Received the Innovation Award for developing a novel coiled tubing intervention method that reduced intervention time and improved well performance.

Certificates

- IWCF Coiled Tubing Supervisor Certification

- API 653 Tank Inspection and Repair Certification

- Crane Operator Certification

- First Aid and CPR Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Coiled Tubing Supervisor

- Highlight your experience and success rate in leading and managing coiled tubing operations.

- Showcase your expertise in developing and implementing innovative procedures to improve operational efficiency and well productivity.

- Emphasize your commitment to safety and your ability to conduct comprehensive risk assessments and implement mitigation measures.

- Demonstrate your leadership and mentoring skills, and your ability to train and develop junior coiled tubing operators.

- Quantify your achievements whenever possible, using specific metrics to illustrate your impact on the organization.

Essential Experience Highlights for a Strong Coiled Tubing Supervisor Resume

- Lead and manage a team of coiled tubing operators to perform complex well interventions, including cleanouts, remedial operations, nitrogen lift, slickline and electric line operations, acid stimulation, and fracturing.

- Develop and implement new coiled tubing running procedures to improve operational efficiency and well productivity.

- Supervise the installation and operation of high-pressure coiled tubing units, ensuring safe and efficient operations.

- Conduct comprehensive risk assessments and implement mitigation measures to ensure the safety of coiled tubing operations.

- Train and mentor junior coiled tubing operators, fostering a high-performing team and ensuring the transfer of knowledge.

- Collaborate with engineers and geologists to optimize coiled tubing interventions, maximizing production and minimizing well damage.

- Manage coiled tubing equipment and materials, ensuring proper inventory management and optimal utilization.

Frequently Asked Questions (FAQ’s) For Coiled Tubing Supervisor

What is the role of a Coiled Tubing Supervisor?

A Coiled Tubing Supervisor is responsible for leading and managing coiled tubing operations, including planning, execution, and evaluation. They ensure the safe and efficient operation of coiled tubing units, and work closely with engineers and geologists to optimize well interventions.

What are the key skills required for a Coiled Tubing Supervisor?

Key skills for a Coiled Tubing Supervisor include expertise in coiled tubing operations, knowledge of wellbore cleanout and remedial operations, nitrogen lift well intervention, slickline and electric line operations, acid stimulation and fracturing, and coiled tubing intervention.

What is the career path for a Coiled Tubing Supervisor?

The career path for a Coiled Tubing Supervisor typically involves starting as a Coiled Tubing Operator, then progressing to a Coiled Tubing Supervisor, and eventually to a Coiled Tubing Manager or Superintendent.

What is the job outlook for Coiled Tubing Supervisors?

The job outlook for Coiled Tubing Supervisors is expected to be good over the next few years, as the demand for coiled tubing services is increasing due to the growing need for well maintenance and intervention.

What is the salary range for Coiled Tubing Supervisors?

The salary range for Coiled Tubing Supervisors varies depending on experience, location, and company size. According to Indeed, the average salary for a Coiled Tubing Supervisor in the United States is around $100,000 per year.

What are the benefits of working as a Coiled Tubing Supervisor?

Benefits of working as a Coiled Tubing Supervisor include a competitive salary, a challenging and rewarding career, and the opportunity to work on a variety of projects.