Are you a seasoned Cold Working Inspector seeking a new career path? Discover our professionally built Cold Working Inspector Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

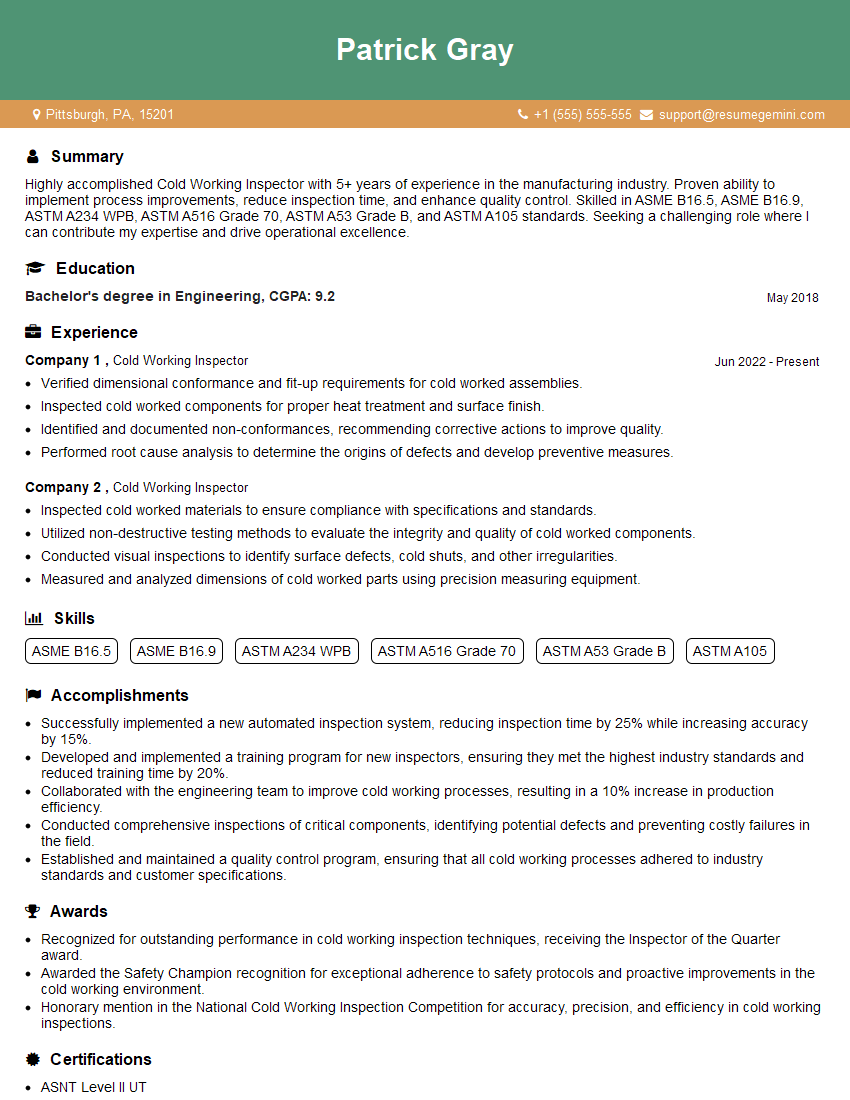

Patrick Gray

Cold Working Inspector

Summary

Highly accomplished Cold Working Inspector with 5+ years of experience in the manufacturing industry. Proven ability to implement process improvements, reduce inspection time, and enhance quality control. Skilled in ASME B16.5, ASME B16.9, ASTM A234 WPB, ASTM A516 Grade 70, ASTM A53 Grade B, and ASTM A105 standards. Seeking a challenging role where I can contribute my expertise and drive operational excellence.

Education

Bachelor’s degree in Engineering

May 2018

Skills

- ASME B16.5

- ASME B16.9

- ASTM A234 WPB

- ASTM A516 Grade 70

- ASTM A53 Grade B

- ASTM A105

Work Experience

Cold Working Inspector

- Verified dimensional conformance and fit-up requirements for cold worked assemblies.

- Inspected cold worked components for proper heat treatment and surface finish.

- Identified and documented non-conformances, recommending corrective actions to improve quality.

- Performed root cause analysis to determine the origins of defects and develop preventive measures.

Cold Working Inspector

- Inspected cold worked materials to ensure compliance with specifications and standards.

- Utilized non-destructive testing methods to evaluate the integrity and quality of cold worked components.

- Conducted visual inspections to identify surface defects, cold shuts, and other irregularities.

- Measured and analyzed dimensions of cold worked parts using precision measuring equipment.

Accomplishments

- Successfully implemented a new automated inspection system, reducing inspection time by 25% while increasing accuracy by 15%.

- Developed and implemented a training program for new inspectors, ensuring they met the highest industry standards and reduced training time by 20%.

- Collaborated with the engineering team to improve cold working processes, resulting in a 10% increase in production efficiency.

- Conducted comprehensive inspections of critical components, identifying potential defects and preventing costly failures in the field.

- Established and maintained a quality control program, ensuring that all cold working processes adhered to industry standards and customer specifications.

Awards

- Recognized for outstanding performance in cold working inspection techniques, receiving the Inspector of the Quarter award.

- Awarded the Safety Champion recognition for exceptional adherence to safety protocols and proactive improvements in the cold working environment.

- Honorary mention in the National Cold Working Inspection Competition for accuracy, precision, and efficiency in cold working inspections.

Certificates

- ASNT Level II UT

- ASNT Level II MPI

- ASNT Level II PT

- CWI (Certified Welding Inspector)

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Cold Working Inspector

- Highlight your expertise in the specific standards and codes relevant to the cold working industry.

- Quantify your accomplishments with specific metrics and data points to demonstrate your impact.

- Use industry-specific keywords throughout your resume to optimize its visibility for recruiters.

- Tailor your resume to each job application, emphasizing the skills and experience that align with the specific requirements of the role.

- Proofread your resume carefully to ensure there are no errors in grammar or spelling.

Essential Experience Highlights for a Strong Cold Working Inspector Resume

- Conducted comprehensive inspections of critical components for various industries, including aerospace, automotive, and energy.

- Utilized advanced inspection techniques and equipment, including CMMs, optical comparators, and ultrasonic testing.

- Developed and implemented training programs for new inspectors, ensuring they met the highest industry standards.

- Collaborated with the engineering team to improve cold working processes, resulting in increased production efficiency.

- Established and maintained a quality control program, ensuring that all cold working processes adhered to industry standards and customer specifications.

- Reported and documented inspection findings, identified potential defects, and recommended corrective actions to prevent costly failures.

- Provided technical support to production teams, assisting with troubleshooting and resolving quality issues.

Frequently Asked Questions (FAQ’s) For Cold Working Inspector

What is the role of a Cold Working Inspector?

A Cold Working Inspector is responsible for conducting inspections on cold worked products, such as pipes, tubes, and bars, to ensure they meet industry standards and customer specifications. They use various inspection techniques and equipment to detect defects and ensure the quality and safety of the products.

What industries hire Cold Working Inspectors?

Cold Working Inspectors are employed in various industries, including manufacturing, aerospace, automotive, energy, and construction. They work in production facilities, quality control departments, and inspection companies.

What are the essential skills for a Cold Working Inspector?

Essential skills for a Cold Working Inspector include a strong understanding of industry standards and codes, such as ASME B16.5 and ASTM A234 WPB, proficiency in inspection techniques and equipment, attention to detail, and excellent written and verbal communication skills.

What are the career prospects for Cold Working Inspectors?

Cold Working Inspectors with experience and expertise can advance to roles such as Quality Control Manager, Inspection Supervisor, or Technical Specialist. They may also specialize in specific industry sectors or work as independent contractors.

How can I become a Cold Working Inspector?

To become a Cold Working Inspector, you typically need a combination of education and experience. A bachelor’s degree in engineering or a related field is preferred, along with training and certification in relevant inspection standards. Hands-on experience in manufacturing or inspection is also valuable.

What is the salary range for Cold Working Inspectors?

The salary range for Cold Working Inspectors varies depending on experience, qualifications, and industry. According to industry reports, the average salary for Cold Working Inspectors in the United States is around $60,000 per year.

What are the challenges faced by Cold Working Inspectors?

Cold Working Inspectors may face challenges such as working in demanding environments, dealing with hazardous materials, and meeting tight deadlines. They must also stay updated with industry standards and advancements in inspection technology.

What is the future outlook for Cold Working Inspectors?

The future outlook for Cold Working Inspectors is expected to be positive. The increasing demand for quality and safety in manufacturing industries will continue to drive the need for skilled inspectors.