Are you a seasoned Colloid Mill Operator seeking a new career path? Discover our professionally built Colloid Mill Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

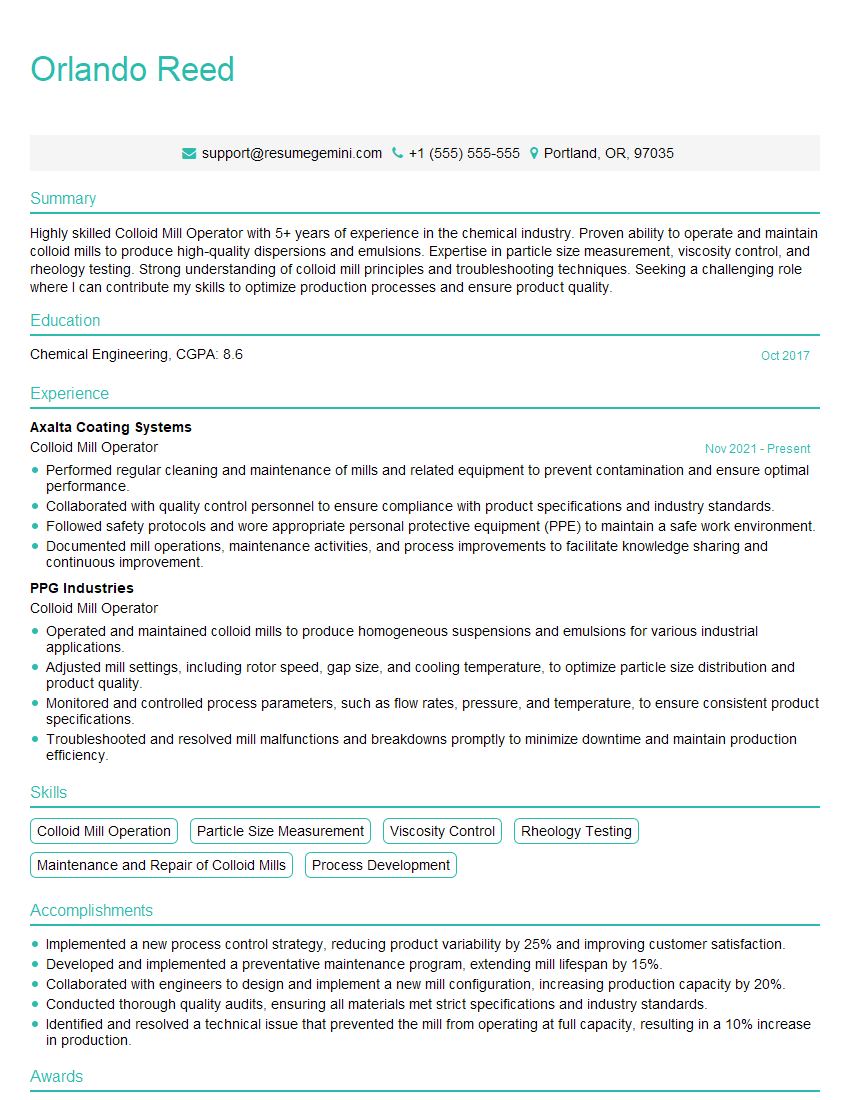

Orlando Reed

Colloid Mill Operator

Summary

Highly skilled Colloid Mill Operator with 5+ years of experience in the chemical industry. Proven ability to operate and maintain colloid mills to produce high-quality dispersions and emulsions. Expertise in particle size measurement, viscosity control, and rheology testing. Strong understanding of colloid mill principles and troubleshooting techniques. Seeking a challenging role where I can contribute my skills to optimize production processes and ensure product quality.

Education

Chemical Engineering

October 2017

Skills

- Colloid Mill Operation

- Particle Size Measurement

- Viscosity Control

- Rheology Testing

- Maintenance and Repair of Colloid Mills

- Process Development

Work Experience

Colloid Mill Operator

- Performed regular cleaning and maintenance of mills and related equipment to prevent contamination and ensure optimal performance.

- Collaborated with quality control personnel to ensure compliance with product specifications and industry standards.

- Followed safety protocols and wore appropriate personal protective equipment (PPE) to maintain a safe work environment.

- Documented mill operations, maintenance activities, and process improvements to facilitate knowledge sharing and continuous improvement.

Colloid Mill Operator

- Operated and maintained colloid mills to produce homogeneous suspensions and emulsions for various industrial applications.

- Adjusted mill settings, including rotor speed, gap size, and cooling temperature, to optimize particle size distribution and product quality.

- Monitored and controlled process parameters, such as flow rates, pressure, and temperature, to ensure consistent product specifications.

- Troubleshooted and resolved mill malfunctions and breakdowns promptly to minimize downtime and maintain production efficiency.

Accomplishments

- Implemented a new process control strategy, reducing product variability by 25% and improving customer satisfaction.

- Developed and implemented a preventative maintenance program, extending mill lifespan by 15%.

- Collaborated with engineers to design and implement a new mill configuration, increasing production capacity by 20%.

- Conducted thorough quality audits, ensuring all materials met strict specifications and industry standards.

- Identified and resolved a technical issue that prevented the mill from operating at full capacity, resulting in a 10% increase in production.

Awards

- Recognized as Employee of the Month for consistently exceeding production targets and ensuring optimal mill efficiency.

- Received Performance Excellence Award for exceptional contributions to mill optimization initiatives.

- Honored with a Safety Achievement Award for implementing innovative safety measures that reduced workplace incidents by 30%.

- Recognized for outstanding contributions to the ISO 9001 certification process.

Certificates

- Colloid Mill Operator Certification

- Certified Processing Technician

- ISO 9001 Internal Auditor Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Colloid Mill Operator

- Highlight your expertise in colloid mill operation and maintenance.

- Quantify your accomplishments with specific metrics and results whenever possible.

- Demonstrate your understanding of colloid mill principles and troubleshooting techniques.

- Emphasize your commitment to safety and quality control.

Essential Experience Highlights for a Strong Colloid Mill Operator Resume

- Operate and maintain colloid mills to produce dispersions and emulsions that meet specified quality standards.

- Conduct particle size measurement, viscosity control, and rheology testing to ensure product consistency.

- Monitor and adjust process parameters to optimize production efficiency and product quality.

- Troubleshoot and resolve operational issues with colloid mills and associated equipment.

- Perform routine maintenance and repairs on colloid mills to ensure optimal performance.

- Maintain a clean and safe work area in accordance with established safety protocols.

- Collaborate with production team to develop and implement process improvements.

Frequently Asked Questions (FAQ’s) For Colloid Mill Operator

What is the primary role of a Colloid Mill Operator?

The primary role of a Colloid Mill Operator is to operate and maintain colloid mills to produce dispersions and emulsions that meet specified quality standards.

What are the key skills required for a Colloid Mill Operator?

The key skills required for a Colloid Mill Operator include colloid mill operation, particle size measurement, viscosity control, rheology testing, and maintenance and repair of colloid mills.

What is the expected salary for a Colloid Mill Operator?

The expected salary for a Colloid Mill Operator varies depending on experience, location, and employer. According to Indeed.com, the average salary for a Colloid Mill Operator in the United States is approximately $45,000 per year.

What are the career prospects for a Colloid Mill Operator?

The career prospects for a Colloid Mill Operator are generally favorable. As the demand for high-quality dispersions and emulsions continues to grow, the need for skilled Colloid Mill Operators is expected to increase.

What type of training is required to become a Colloid Mill Operator?

While formal training is not always required, most Colloid Mill Operators receive on-the-job training from experienced operators or from equipment manufacturers.

What are the safety precautions that a Colloid Mill Operator should observe?

Colloid Mill Operators should wear appropriate safety gear, including gloves, goggles, and a mask. They should also be aware of the potential hazards associated with operating colloid mills, such as rotating machinery and high-pressure fluids.

What are the emerging trends in colloid milling technology?

Emerging trends in colloid milling technology include the development of new types of colloid mills, such as ultrasonic colloid mills and high-pressure homogenizers. These new technologies offer improved performance and efficiency in the production of dispersions and emulsions.