Are you a seasoned Comb Setter seeking a new career path? Discover our professionally built Comb Setter Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

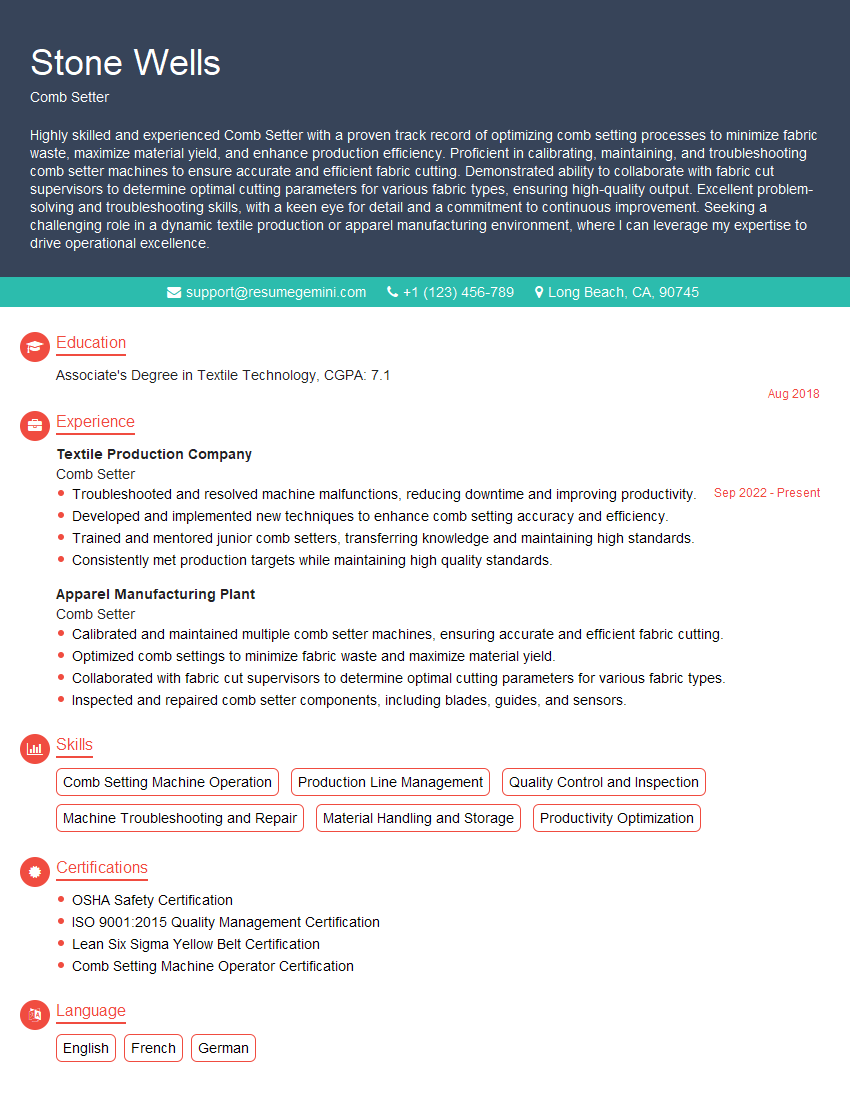

Stone Wells

Comb Setter

Summary

Highly skilled and experienced Comb Setter with a proven track record of optimizing comb setting processes to minimize fabric waste, maximize material yield, and enhance production efficiency. Proficient in calibrating, maintaining, and troubleshooting comb setter machines to ensure accurate and efficient fabric cutting. Demonstrated ability to collaborate with fabric cut supervisors to determine optimal cutting parameters for various fabric types, ensuring high-quality output. Excellent problem-solving and troubleshooting skills, with a keen eye for detail and a commitment to continuous improvement. Seeking a challenging role in a dynamic textile production or apparel manufacturing environment, where I can leverage my expertise to drive operational excellence.

Education

Associate’s Degree in Textile Technology

August 2018

Skills

- Comb Setting Machine Operation

- Production Line Management

- Quality Control and Inspection

- Machine Troubleshooting and Repair

- Material Handling and Storage

- Productivity Optimization

Work Experience

Comb Setter

- Troubleshooted and resolved machine malfunctions, reducing downtime and improving productivity.

- Developed and implemented new techniques to enhance comb setting accuracy and efficiency.

- Trained and mentored junior comb setters, transferring knowledge and maintaining high standards.

- Consistently met production targets while maintaining high quality standards.

Comb Setter

- Calibrated and maintained multiple comb setter machines, ensuring accurate and efficient fabric cutting.

- Optimized comb settings to minimize fabric waste and maximize material yield.

- Collaborated with fabric cut supervisors to determine optimal cutting parameters for various fabric types.

- Inspected and repaired comb setter components, including blades, guides, and sensors.

Certificates

- OSHA Safety Certification

- ISO 9001:2015 Quality Management Certification

- Lean Six Sigma Yellow Belt Certification

- Comb Setting Machine Operator Certification

Languages

- English

- French

- German

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Comb Setter

- Highlight your expertise in calibrating and maintaining comb setter machines, emphasizing your ability to ensure accurate and efficient fabric cutting.

- Showcase your skills in optimizing comb settings to minimize fabric waste and maximize material yield, demonstrating your commitment to cost-effectiveness.

- Emphasize your experience in collaborating with fabric cut supervisors to determine optimal cutting parameters, showcasing your understanding of fabric cutting processes.

- Mention your problem-solving and troubleshooting capabilities, highlighting your ability to quickly identify and resolve machine malfunctions, reducing downtime and enhancing productivity.

- Consider including any additional skills or experience relevant to the textile or apparel manufacturing industry, such as fabric inspection, quality control, or production planning.

Essential Experience Highlights for a Strong Comb Setter Resume

- Calibrated and maintained multiple comb setter machines, ensuring accurate and efficient fabric cutting.

- Optimized comb settings to minimize fabric waste and maximize material yield.

- Collaborated with fabric cut supervisors to determine optimal cutting parameters for various fabric types.

- Inspected and repaired comb setter components, including blades, guides, and sensors.

- Troubleshooted and resolved machine malfunctions, reducing downtime and improving productivity.

- Developed and implemented new techniques to enhance comb setting accuracy and efficiency.

- Trained and mentored junior comb setters, transferring knowledge and maintaining high standards.

Frequently Asked Questions (FAQ’s) For Comb Setter

What are the primary responsibilities of a Comb Setter?

A Comb Setter is responsible for calibrating, maintaining, and optimizing comb setting machines used in textile production, ensuring accurate and efficient fabric cutting, maximizing material yield, minimizing waste, and supporting overall production efficiency.

What qualifications are required to become a Comb Setter?

Typically, a high school diploma or equivalent is sufficient to become a Comb Setter. However, some employers may prefer candidates with an associate’s degree in textile technology or related field, or those with prior experience in textile manufacturing or fabric cutting.

What skills are essential for a successful Comb Setter?

A successful Comb Setter should possess strong mechanical aptitude, attention to detail, and problem-solving skills, along with proficiency in operating and maintaining comb setting machines. They should also have a good understanding of fabric types and cutting parameters, and be able to work independently and as part of a team.

What is the job outlook for Comb Setters?

The job outlook for Comb Setters is expected to be stable in the coming years, as the demand for textiles and apparel remains steady. However, technological advancements in fabric cutting and automation may affect the job market, requiring Comb Setters to adapt and acquire new skills.

What are the career advancement opportunities for Comb Setters?

Comb Setters can advance their careers by gaining experience and developing expertise in fabric cutting and textile production processes. They may progress to roles such as Fabric Cutter, Textile Production Supervisor, or Quality Control Inspector.

What industries employ Comb Setters?

Comb Setters are primarily employed in the textile and apparel manufacturing industry, working in mills, factories, and production plants. They are responsible for preparing fabrics for cutting and ensuring the accuracy and efficiency of the cutting process.

What is the salary range for Comb Setters?

The salary range for Comb Setters can vary depending on factors such as experience, location, and industry. According to Indeed, the average salary for a Comb Setter in the United States is around $30,000 per year.

What is the work environment of a Comb Setter like?

Comb Setters typically work in industrial settings, such as factories or mills, where they operate and maintain machinery. They may be exposed to noise, dust, and chemicals, so appropriate safety gear and adherence to safety protocols are essential.