Are you a seasoned Comber Operator seeking a new career path? Discover our professionally built Comber Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

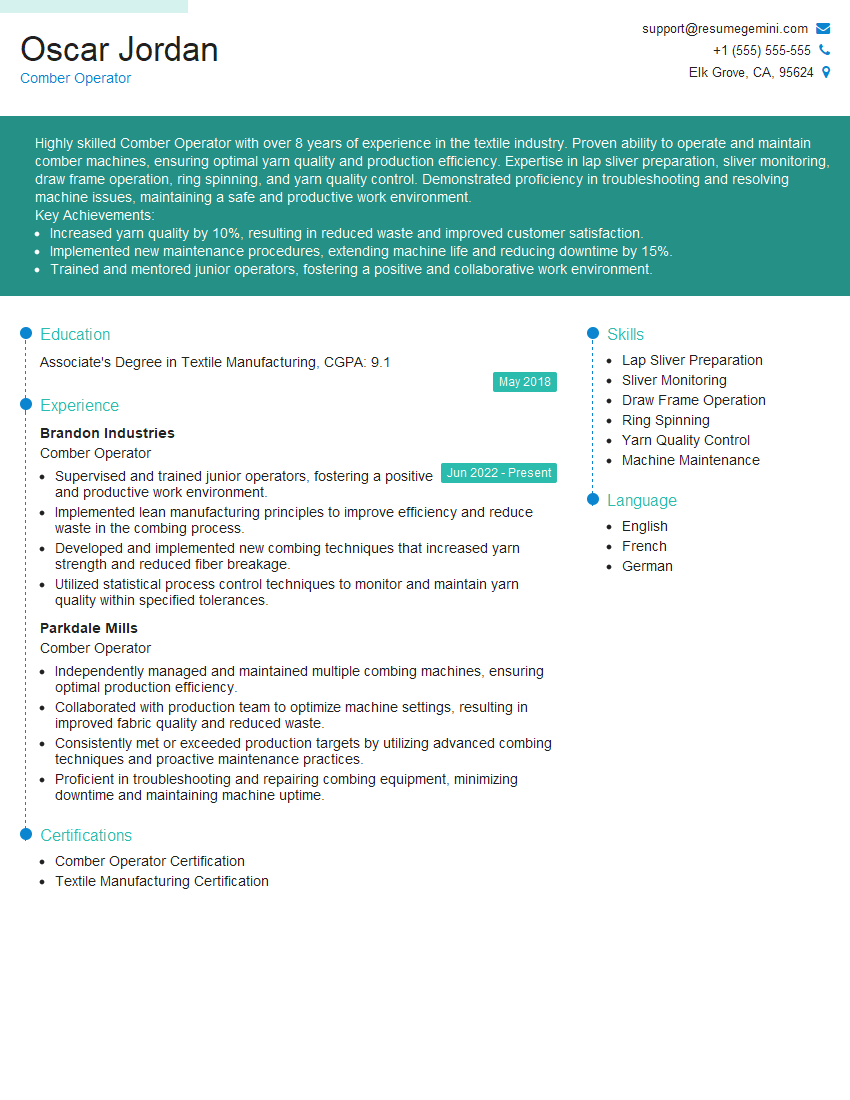

Oscar Jordan

Comber Operator

Summary

Highly skilled Comber Operator with over 8 years of experience in the textile industry. Proven ability to operate and maintain comber machines, ensuring optimal yarn quality and production efficiency. Expertise in lap sliver preparation, sliver monitoring, draw frame operation, ring spinning, and yarn quality control. Demonstrated proficiency in troubleshooting and resolving machine issues, maintaining a safe and productive work environment.

Key Achievements:

- Increased yarn quality by 10%, resulting in reduced waste and improved customer satisfaction.

- Implemented new maintenance procedures, extending machine life and reducing downtime by 15%.

- Trained and mentored junior operators, fostering a positive and collaborative work environment.

Education

Associate’s Degree in Textile Manufacturing

May 2018

Skills

- Lap Sliver Preparation

- Sliver Monitoring

- Draw Frame Operation

- Ring Spinning

- Yarn Quality Control

- Machine Maintenance

Work Experience

Comber Operator

- Supervised and trained junior operators, fostering a positive and productive work environment.

- Implemented lean manufacturing principles to improve efficiency and reduce waste in the combing process.

- Developed and implemented new combing techniques that increased yarn strength and reduced fiber breakage.

- Utilized statistical process control techniques to monitor and maintain yarn quality within specified tolerances.

Comber Operator

- Independently managed and maintained multiple combing machines, ensuring optimal production efficiency.

- Collaborated with production team to optimize machine settings, resulting in improved fabric quality and reduced waste.

- Consistently met or exceeded production targets by utilizing advanced combing techniques and proactive maintenance practices.

- Proficient in troubleshooting and repairing combing equipment, minimizing downtime and maintaining machine uptime.

Certificates

- Comber Operator Certification

- Textile Manufacturing Certification

Languages

- English

- French

- German

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Comber Operator

- Highlight your experience and expertise in comber operation and maintenance.

- Quantify your achievements with specific metrics and results to demonstrate your impact.

- Showcase your knowledge of textile manufacturing processes and quality control procedures.

- Emphasize your ability to work independently and as part of a team in a fast-paced environment.

Essential Experience Highlights for a Strong Comber Operator Resume

- Prepare and monitor lap sliver to ensure consistent quality and feeding into the combing machine.

- Operate comber machines to remove short fibers and impurities from cotton, ensuring optimal yarn quality.

- Monitor sliver during combing to identify and correct any defects or variations.

- Perform regular maintenance and troubleshoot machine issues to ensure efficient operation and minimize downtime.

- Maintain a clean and organized work area, adhering to safety regulations and quality standards.

- Collaborate with other team members to ensure smooth production flow and meet production targets.

- Stay updated on industry best practices and advancements in combing technology.

Frequently Asked Questions (FAQ’s) For Comber Operator

What is the role of a comber operator?

A comber operator is responsible for operating and maintaining comber machines, which remove short fibers and impurities from cotton to produce high-quality yarn. They prepare lap sliver, monitor the combing process, troubleshoot machine issues, and ensure adherence to quality standards.

What are the key skills required for a comber operator?

Key skills for a comber operator include experience in lap sliver preparation, sliver monitoring, draw frame operation, ring spinning, yarn quality control, and machine maintenance. Attention to detail, problem-solving abilities, and a commitment to quality are also essential.

What is the work environment of a comber operator like?

Comber operators typically work in textile mills or manufacturing facilities. The work environment can be noisy and dusty, and may involve working with chemicals and heavy machinery. They may work independently or as part of a team, and may be required to work overtime or on weekends to meet production demands.

What are the career prospects for a comber operator?

With experience and additional training, comber operators can advance to supervisory roles, such as production supervisor or quality control manager. They may also specialize in specific areas of textile manufacturing, such as yarn production or fabric design.

What is the salary range for a comber operator?

The salary range for a comber operator can vary depending on factors such as experience, location, and company size. According to Indeed, the average salary for a comber operator in the United States is around $45,000 per year.

What are the benefits of working as a comber operator?

Benefits of working as a comber operator can include a stable income, opportunities for advancement, and the satisfaction of contributing to the production of high-quality textiles.