Are you a seasoned Combination Machine Tool Setter seeking a new career path? Discover our professionally built Combination Machine Tool Setter Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

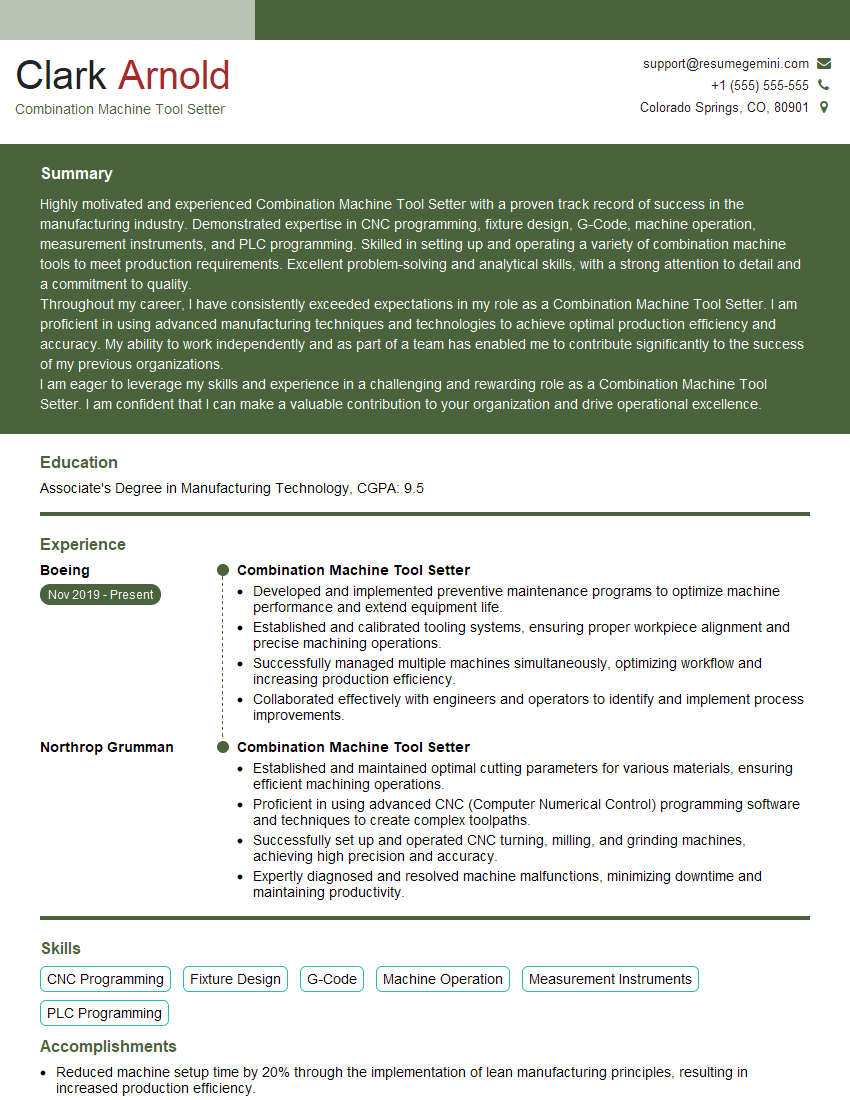

Clark Arnold

Combination Machine Tool Setter

Summary

Highly motivated and experienced Combination Machine Tool Setter with a proven track record of success in the manufacturing industry. Demonstrated expertise in CNC programming, fixture design, G-Code, machine operation, measurement instruments, and PLC programming. Skilled in setting up and operating a variety of combination machine tools to meet production requirements. Excellent problem-solving and analytical skills, with a strong attention to detail and a commitment to quality.

Throughout my career, I have consistently exceeded expectations in my role as a Combination Machine Tool Setter. I am proficient in using advanced manufacturing techniques and technologies to achieve optimal production efficiency and accuracy. My ability to work independently and as part of a team has enabled me to contribute significantly to the success of my previous organizations.

I am eager to leverage my skills and experience in a challenging and rewarding role as a Combination Machine Tool Setter. I am confident that I can make a valuable contribution to your organization and drive operational excellence.

Education

Associate’s Degree in Manufacturing Technology

October 2015

Skills

- CNC Programming

- Fixture Design

- G-Code

- Machine Operation

- Measurement Instruments

- PLC Programming

Work Experience

Combination Machine Tool Setter

- Developed and implemented preventive maintenance programs to optimize machine performance and extend equipment life.

- Established and calibrated tooling systems, ensuring proper workpiece alignment and precise machining operations.

- Successfully managed multiple machines simultaneously, optimizing workflow and increasing production efficiency.

- Collaborated effectively with engineers and operators to identify and implement process improvements.

Combination Machine Tool Setter

- Established and maintained optimal cutting parameters for various materials, ensuring efficient machining operations.

- Proficient in using advanced CNC (Computer Numerical Control) programming software and techniques to create complex toolpaths.

- Successfully set up and operated CNC turning, milling, and grinding machines, achieving high precision and accuracy.

- Expertly diagnosed and resolved machine malfunctions, minimizing downtime and maintaining productivity.

Accomplishments

- Reduced machine setup time by 20% through the implementation of lean manufacturing principles, resulting in increased production efficiency.

- Developed and implemented a preventative maintenance program, reducing machine downtime by 15% and extending equipment lifespan.

- Successfully trained and mentored new machine tool setters, improving their skills and contributing to team success.

- Collaborated with engineers to develop new tool designs, resulting in increased cutting efficiency and improved product quality.

- Utilized advanced measuring techniques to ensure precise alignment and calibration of machine tools, achieving optimal performance.

Awards

- Received the Machine Tool Setter of the Year award for outstanding performance in setting up and optimizing CNC machines.

- Consistently exceeded quality standards, achieving a zerodefect rate for all machined parts.

- Recognized for exceptional problemsolving skills, resolving complex setup issues that resulted in significant cost savings.

- Received certification in CNC programming, enhancing my ability to optimize machine settings and improve production processes.

Certificates

- Certified Numerical Control Programmer (CNCP)

- Certified Master Toolmaker (CMfgT)

- Certified Manufacturing Technologist (CMfgT)

- Precision Measurement Instrument (PMI)

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Combination Machine Tool Setter

- Highlight your technical skills and experience in CNC programming, fixture design, and machine operation.

- Showcase your ability to work independently and as part of a team.

- Quantify your accomplishments whenever possible, using specific metrics to demonstrate your impact.

- Proofread your resume carefully before submitting it, ensuring there are no errors in grammar or spelling.

Essential Experience Highlights for a Strong Combination Machine Tool Setter Resume

- Set up and operate a variety of combination machine tools, including CNC lathes, mills, and grinders.

- Develop and implement CNC programs to optimize production efficiency and accuracy.

- Design and build fixtures to hold workpieces securely during machining operations.

- Inspect finished parts to ensure they meet specifications and quality standards.

- Troubleshoot and resolve machine malfunctions, ensuring minimal downtime.

- Maintain a clean and organized work area, adhering to safety regulations.

Frequently Asked Questions (FAQ’s) For Combination Machine Tool Setter

What is the role of a Combination Machine Tool Setter?

A Combination Machine Tool Setter is responsible for setting up and operating a variety of combination machine tools, including CNC lathes, mills, and grinders. They develop and implement CNC programs to optimize production efficiency and accuracy, design and build fixtures to hold workpieces securely during machining operations, inspect finished parts to ensure they meet specifications and quality standards, troubleshoot and resolve machine malfunctions, and maintain a clean and organized work area.

What are the qualifications for becoming a Combination Machine Tool Setter?

To become a Combination Machine Tool Setter, you typically need an associate’s degree in manufacturing technology or a related field, combined with several years of experience in a manufacturing environment. Strong technical skills in CNC programming, fixture design, and machine operation are essential, as well as the ability to work independently and as part of a team.

What are the career prospects for Combination Machine Tool Setters?

Combination Machine Tool Setters are in high demand in the manufacturing industry. With the increasing use of CNC machines and automation, skilled setters are needed to ensure that production runs smoothly and efficiently. Career advancement opportunities include moving into supervisory or management roles, or specializing in a particular area of machine tool setting.

What is the average salary for Combination Machine Tool Setters?

The average salary for Combination Machine Tool Setters varies depending on experience, location, and industry. According to the U.S. Bureau of Labor Statistics, the median annual salary for CNC machine tool programmers was $56,380 in May 2021.

What are the challenges of being a Combination Machine Tool Setter?

Some of the challenges of being a Combination Machine Tool Setter include working with complex machinery, meeting tight production deadlines, and ensuring that parts meet high quality standards. Setters must also be able to troubleshoot and resolve machine malfunctions, which can be time-consuming and requires a deep understanding of machine operation.