Are you a seasoned Composite Technician seeking a new career path? Discover our professionally built Composite Technician Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

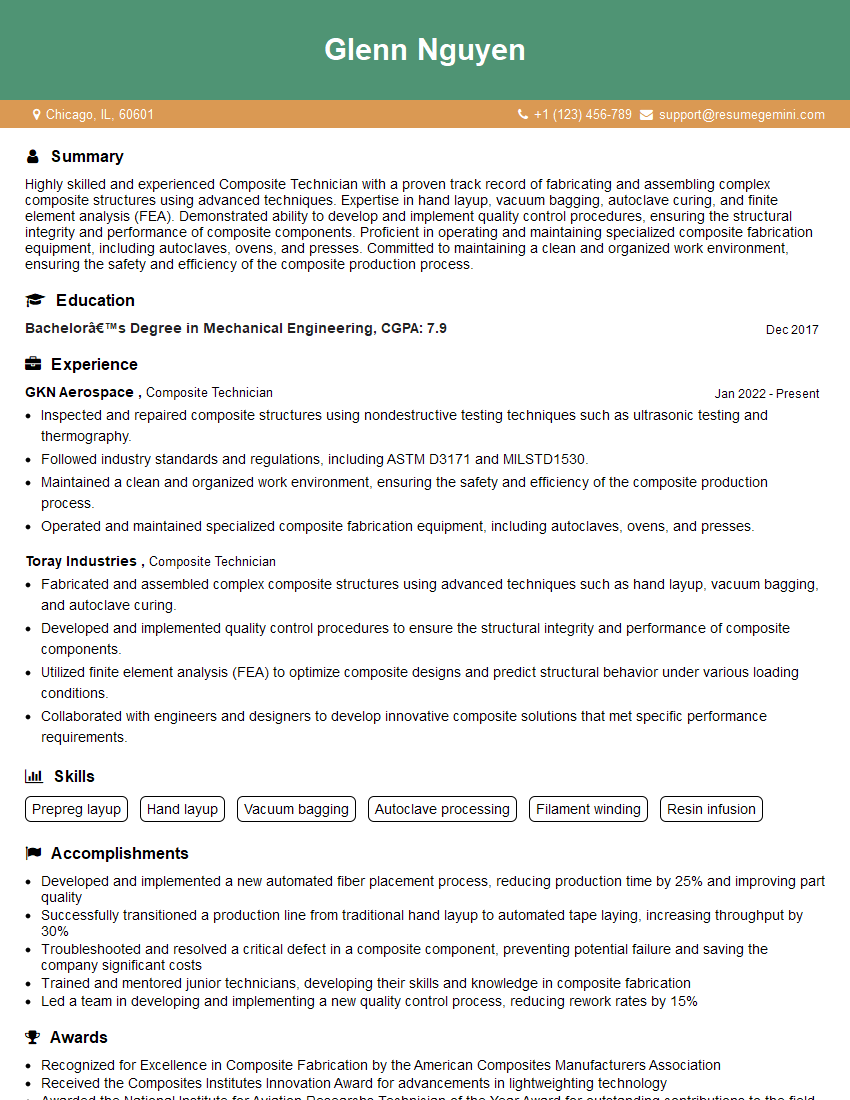

Glenn Nguyen

Composite Technician

Summary

Highly skilled and experienced Composite Technician with a proven track record of fabricating and assembling complex composite structures using advanced techniques. Expertise in hand layup, vacuum bagging, autoclave curing, and finite element analysis (FEA). Demonstrated ability to develop and implement quality control procedures, ensuring the structural integrity and performance of composite components. Proficient in operating and maintaining specialized composite fabrication equipment, including autoclaves, ovens, and presses. Committed to maintaining a clean and organized work environment, ensuring the safety and efficiency of the composite production process.

Education

Bachelor’s Degree in Mechanical Engineering

December 2017

Skills

- Prepreg layup

- Hand layup

- Vacuum bagging

- Autoclave processing

- Filament winding

- Resin infusion

Work Experience

Composite Technician

- Inspected and repaired composite structures using nondestructive testing techniques such as ultrasonic testing and thermography.

- Followed industry standards and regulations, including ASTM D3171 and MILSTD1530.

- Maintained a clean and organized work environment, ensuring the safety and efficiency of the composite production process.

- Operated and maintained specialized composite fabrication equipment, including autoclaves, ovens, and presses.

Composite Technician

- Fabricated and assembled complex composite structures using advanced techniques such as hand layup, vacuum bagging, and autoclave curing.

- Developed and implemented quality control procedures to ensure the structural integrity and performance of composite components.

- Utilized finite element analysis (FEA) to optimize composite designs and predict structural behavior under various loading conditions.

- Collaborated with engineers and designers to develop innovative composite solutions that met specific performance requirements.

Accomplishments

- Developed and implemented a new automated fiber placement process, reducing production time by 25% and improving part quality

- Successfully transitioned a production line from traditional hand layup to automated tape laying, increasing throughput by 30%

- Troubleshooted and resolved a critical defect in a composite component, preventing potential failure and saving the company significant costs

- Trained and mentored junior technicians, developing their skills and knowledge in composite fabrication

- Led a team in developing and implementing a new quality control process, reducing rework rates by 15%

Awards

- Recognized for Excellence in Composite Fabrication by the American Composites Manufacturers Association

- Received the Composites Institutes Innovation Award for advancements in lightweighting technology

- Awarded the National Institute for Aviation Researchs Technician of the Year Award for outstanding contributions to the field

Certificates

- Certified Composite Technician (CCT)

- Advanced Certified Composite Technician (ACCT)

- Aerospace Composite Technician (ACT)

- National Institute for Composites Manufacturing (NICoM) certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Composite Technician

- Highlight your hands-on experience and skills in composite fabrication techniques.

- Quantify your accomplishments whenever possible, using specific metrics to demonstrate your impact.

- Showcase your knowledge of industry standards and regulations, as well as your ability to work independently and as part of a team.

- Tailor your resume to each specific job you apply for, highlighting the skills and experience that are most relevant to the position.

Essential Experience Highlights for a Strong Composite Technician Resume

- Fabricate and assemble complex composite structures using advanced techniques such as hand layup, vacuum bagging, and autoclave curing.

- Develop and implement quality control procedures to ensure the structural integrity and performance of composite components.

- Utilize finite element analysis (FEA) to optimize composite designs and predict structural behavior under various loading conditions.

- Collaborate with engineers and designers to develop innovative composite solutions that meet specific performance requirements.

- Inspect and repair composite structures using nondestructive testing techniques such as ultrasonic testing and thermography.

- Follow industry standards and regulations, including ASTM D3171 and MIL-STD-1530.

- Maintain a clean and organized work environment, ensuring the safety and efficiency of the composite production process.

Frequently Asked Questions (FAQ’s) For Composite Technician

What are the key skills required to be a successful Composite Technician?

Key skills for a Composite Technician include proficiency in composite fabrication techniques such as hand layup, vacuum bagging, and autoclave curing. They should also have a strong understanding of composite materials, structural analysis, and quality control procedures.

What industries hire Composite Technicians?

Composite Technicians are employed in a variety of industries, including aerospace, automotive, marine, and wind energy.

What is the career path for a Composite Technician?

With experience, Composite Technicians can advance to supervisory or management roles. They may also specialize in a particular area of composite fabrication, such as design, analysis, or repair.

What is the job outlook for Composite Technicians?

The job outlook for Composite Technicians is expected to be good in the coming years, as the demand for composite materials continues to grow.

What are the salary expectations for Composite Technicians?

Salary expectations for Composite Technicians vary depending on their experience, skills, and location. However, the median annual salary for Composite Technicians is around $60,000.

What are the educational requirements for Composite Technicians?

Most Composite Technicians have a high school diploma or equivalent. However, some employers may prefer candidates with a post-secondary degree in a related field, such as mechanical engineering or materials science.

What are the certifications available for Composite Technicians?

There are a number of certifications available for Composite Technicians, including the Certified Composite Technician (CCT) certification offered by the American Composites Manufacturers Association (ACMA).

What are the professional organizations for Composite Technicians?

There are a number of professional organizations for Composite Technicians, including the American Composites Manufacturers Association (ACMA) and the Society for the Advancement of Material and Process Engineering (SAMPE).