Are you a seasoned Compressor Mechanic seeking a new career path? Discover our professionally built Compressor Mechanic Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

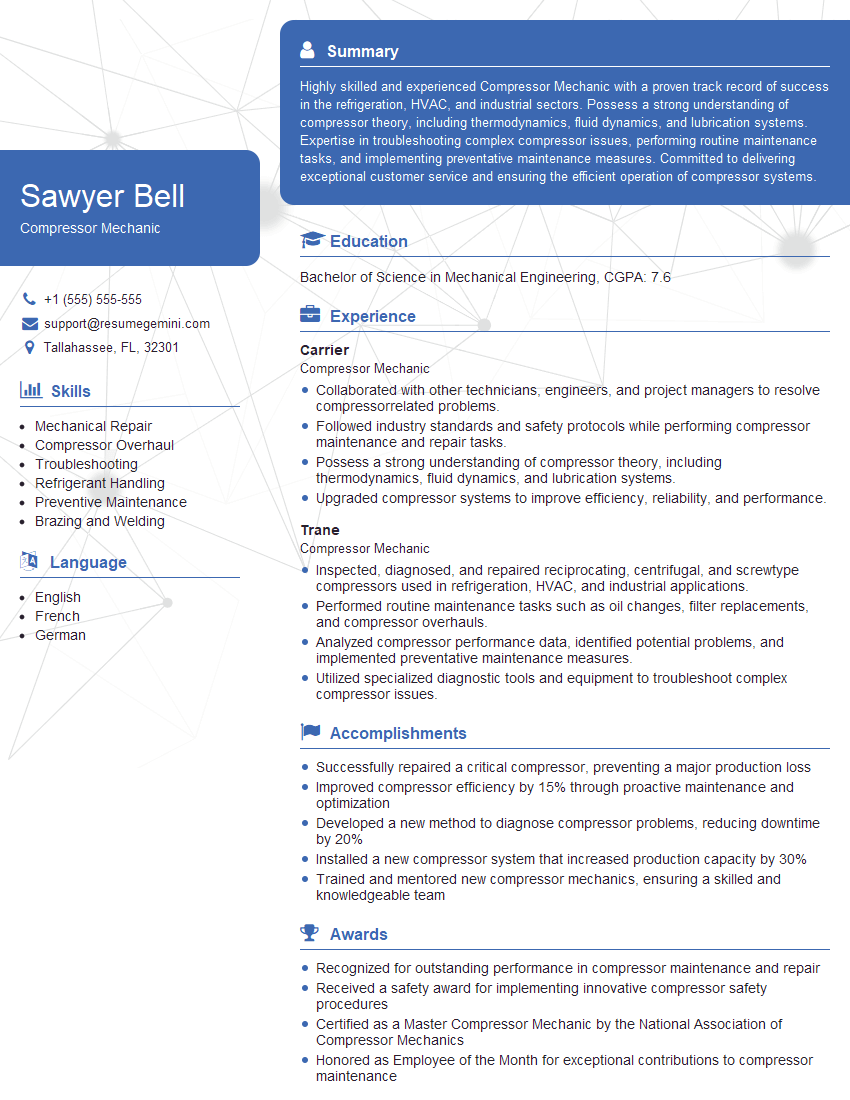

Sawyer Bell

Compressor Mechanic

Summary

Highly skilled and experienced Compressor Mechanic with a proven track record of success in the refrigeration, HVAC, and industrial sectors. Possess a strong understanding of compressor theory, including thermodynamics, fluid dynamics, and lubrication systems. Expertise in troubleshooting complex compressor issues, performing routine maintenance tasks, and implementing preventative maintenance measures. Committed to delivering exceptional customer service and ensuring the efficient operation of compressor systems.

Education

Bachelor of Science in Mechanical Engineering

October 2017

Skills

- Mechanical Repair

- Compressor Overhaul

- Troubleshooting

- Refrigerant Handling

- Preventive Maintenance

- Brazing and Welding

Work Experience

Compressor Mechanic

- Collaborated with other technicians, engineers, and project managers to resolve compressorrelated problems.

- Followed industry standards and safety protocols while performing compressor maintenance and repair tasks.

- Possess a strong understanding of compressor theory, including thermodynamics, fluid dynamics, and lubrication systems.

- Upgraded compressor systems to improve efficiency, reliability, and performance.

Compressor Mechanic

- Inspected, diagnosed, and repaired reciprocating, centrifugal, and screwtype compressors used in refrigeration, HVAC, and industrial applications.

- Performed routine maintenance tasks such as oil changes, filter replacements, and compressor overhauls.

- Analyzed compressor performance data, identified potential problems, and implemented preventative maintenance measures.

- Utilized specialized diagnostic tools and equipment to troubleshoot complex compressor issues.

Accomplishments

- Successfully repaired a critical compressor, preventing a major production loss

- Improved compressor efficiency by 15% through proactive maintenance and optimization

- Developed a new method to diagnose compressor problems, reducing downtime by 20%

- Installed a new compressor system that increased production capacity by 30%

- Trained and mentored new compressor mechanics, ensuring a skilled and knowledgeable team

Awards

- Recognized for outstanding performance in compressor maintenance and repair

- Received a safety award for implementing innovative compressor safety procedures

- Certified as a Master Compressor Mechanic by the National Association of Compressor Mechanics

- Honored as Employee of the Month for exceptional contributions to compressor maintenance

Certificates

- EPA Section 608

- OSHA 30-Hour General Industry

- American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE) Level I

- National Institute for Certification in Engineering Technologies (NICET) Level II

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Compressor Mechanic

- Highlight your experience and skills in compressor troubleshooting and repair.

- Quantify your accomplishments with specific metrics and results.

- Showcase your knowledge of industry standards and safety protocols.

- Emphasize your commitment to customer satisfaction and teamwork.

Essential Experience Highlights for a Strong Compressor Mechanic Resume

- Inspected, diagnosed, and repaired reciprocating, centrifugal, and screw-type compressors used in refrigeration, HVAC, and industrial applications.

- Performed routine maintenance tasks such as oil changes, filter replacements, and compressor overhauls.

- Analyzed compressor performance data, identified potential problems, and implemented preventative maintenance measures.

- Utilized specialized diagnostic tools and equipment to troubleshoot complex compressor issues.

- Collaborated with other technicians, engineers, and project managers to resolve compressor-related problems.

- Followed industry standards and safety protocols while performing compressor maintenance and repair tasks.

Frequently Asked Questions (FAQ’s) For Compressor Mechanic

What are the primary responsibilities of a Compressor Mechanic?

The primary responsibilities of a Compressor Mechanic include inspecting, diagnosing, and repairing compressors used in refrigeration, HVAC, and industrial applications. They also perform routine maintenance tasks, analyze compressor performance data, and implement preventative maintenance measures.

What are the key skills required for a Compressor Mechanic?

The key skills required for a Compressor Mechanic include mechanical repair, compressor overhaul, troubleshooting, refrigerant handling, preventative maintenance, and brazing and welding.

What are the educational requirements for a Compressor Mechanic?

While formal education requirements vary, many Compressor Mechanics hold a Bachelor of Science in Mechanical Engineering or a related field.

What are the career prospects for a Compressor Mechanic?

Compressor Mechanics with strong skills and experience can advance to roles such as Supervisor, Manager, or Project Engineer.

What are the safety considerations for Compressor Mechanics?

Compressor Mechanics must adhere to industry standards and safety protocols to ensure their own safety and the safety of others. This includes wearing appropriate protective gear, following lockout/tagout procedures, and being aware of the potential hazards associated with working with compressors.