Are you a seasoned Compressor Room Operator seeking a new career path? Discover our professionally built Compressor Room Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

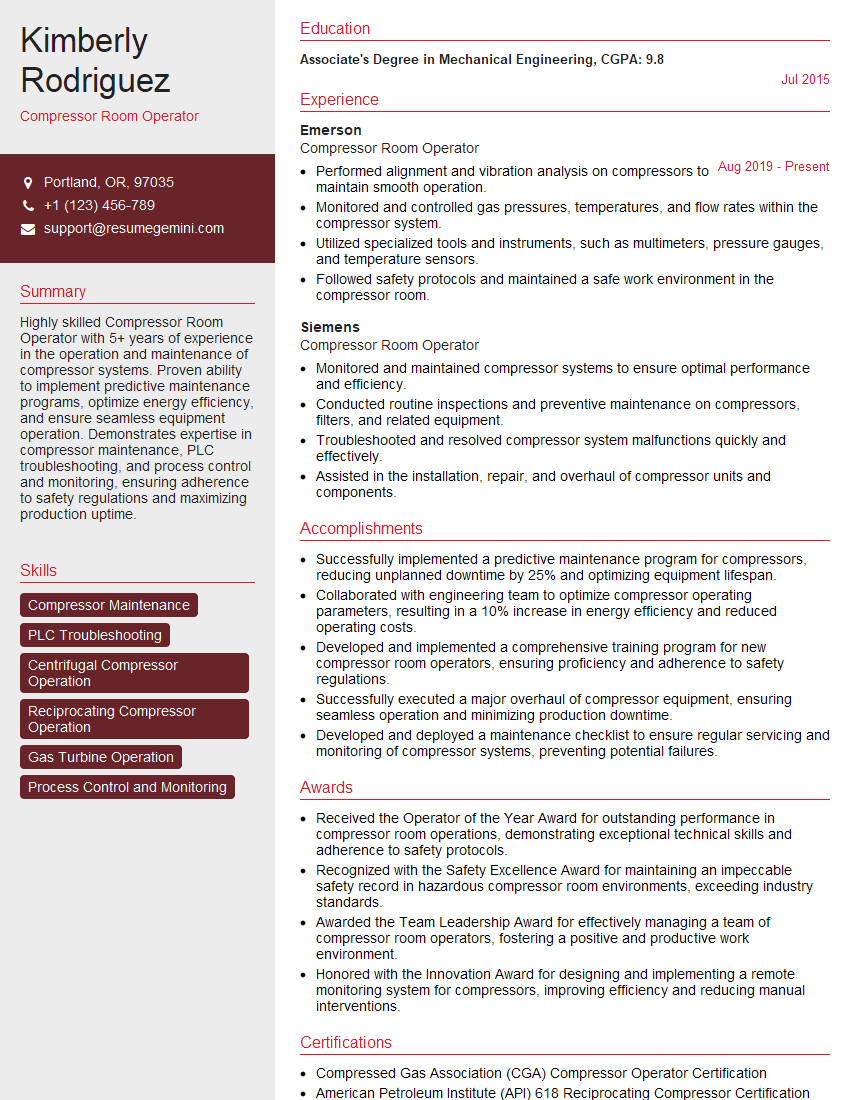

Kimberly Rodriguez

Compressor Room Operator

Summary

Highly skilled Compressor Room Operator with 5+ years of experience in the operation and maintenance of compressor systems. Proven ability to implement predictive maintenance programs, optimize energy efficiency, and ensure seamless equipment operation. Demonstrates expertise in compressor maintenance, PLC troubleshooting, and process control and monitoring, ensuring adherence to safety regulations and maximizing production uptime.

Education

Associate’s Degree in Mechanical Engineering

July 2015

Skills

- Compressor Maintenance

- PLC Troubleshooting

- Centrifugal Compressor Operation

- Reciprocating Compressor Operation

- Gas Turbine Operation

- Process Control and Monitoring

Work Experience

Compressor Room Operator

- Performed alignment and vibration analysis on compressors to maintain smooth operation.

- Monitored and controlled gas pressures, temperatures, and flow rates within the compressor system.

- Utilized specialized tools and instruments, such as multimeters, pressure gauges, and temperature sensors.

- Followed safety protocols and maintained a safe work environment in the compressor room.

Compressor Room Operator

- Monitored and maintained compressor systems to ensure optimal performance and efficiency.

- Conducted routine inspections and preventive maintenance on compressors, filters, and related equipment.

- Troubleshooted and resolved compressor system malfunctions quickly and effectively.

- Assisted in the installation, repair, and overhaul of compressor units and components.

Accomplishments

- Successfully implemented a predictive maintenance program for compressors, reducing unplanned downtime by 25% and optimizing equipment lifespan.

- Collaborated with engineering team to optimize compressor operating parameters, resulting in a 10% increase in energy efficiency and reduced operating costs.

- Developed and implemented a comprehensive training program for new compressor room operators, ensuring proficiency and adherence to safety regulations.

- Successfully executed a major overhaul of compressor equipment, ensuring seamless operation and minimizing production downtime.

- Developed and deployed a maintenance checklist to ensure regular servicing and monitoring of compressor systems, preventing potential failures.

Awards

- Received the Operator of the Year Award for outstanding performance in compressor room operations, demonstrating exceptional technical skills and adherence to safety protocols.

- Recognized with the Safety Excellence Award for maintaining an impeccable safety record in hazardous compressor room environments, exceeding industry standards.

- Awarded the Team Leadership Award for effectively managing a team of compressor room operators, fostering a positive and productive work environment.

- Honored with the Innovation Award for designing and implementing a remote monitoring system for compressors, improving efficiency and reducing manual interventions.

Certificates

- Compressed Gas Association (CGA) Compressor Operator Certification

- American Petroleum Institute (API) 618 Reciprocating Compressor Certification

- National Institute for Occupational Safety and Health (NIOSH) Occupational Safety and Health for Compressor Operators

- American Society of Mechanical Engineers (ASME) Boiler and Pressure Vessel Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Compressor Room Operator

- Highlight your hands-on experience with different types of compressors, including centrifugal and reciprocating compressors.

- Demonstrate your ability to implement and manage predictive maintenance programs.

- Quantify your accomplishments, such as reducing unplanned downtime or increasing energy efficiency.

- Emphasize your knowledge of safety regulations and adherence to industry best practices.

Essential Experience Highlights for a Strong Compressor Room Operator Resume

- Operate and monitor compressors, ensuring optimal performance and efficiency.

- Perform routine maintenance and troubleshooting to identify and resolve potential issues.

- Implement predictive maintenance strategies to minimize unplanned downtime and extend equipment lifespan.

- Collaborate with engineering teams to analyze and optimize compressor operating parameters.

- Conduct training programs for new operators, emphasizing safety protocols and equipment operating procedures.

- Maintain accurate records and documentation of compressor performance and maintenance activities.

Frequently Asked Questions (FAQ’s) For Compressor Room Operator

What are the key skills required for a Compressor Room Operator?

Compressor maintenance, PLC troubleshooting, process control and monitoring, and a strong understanding of safety regulations are essential skills for a Compressor Room Operator.

What are the career opportunities for a Compressor Room Operator?

Experienced Compressor Room Operators can advance to roles such as Maintenance Supervisor, Production Supervisor, or Engineering Technician.

What is the average salary for a Compressor Room Operator?

The average salary for a Compressor Room Operator varies depending on experience and location, but typically ranges from $50,000 to $75,000 per year.

What is the job outlook for Compressor Room Operators?

The job outlook for Compressor Room Operators is expected to remain stable, with steady growth in demand due to the increasing use of compressors in various industries.

What are the educational requirements for a Compressor Room Operator?

Most Compressor Room Operators have an Associate’s Degree in Mechanical Engineering or a related field, combined with hands-on training and experience.

What certifications are beneficial for a Compressor Room Operator?

Certifications in compressor maintenance, PLC programming, and process control can enhance the credibility and marketability of Compressor Room Operators.

What are the safety considerations for Compressor Room Operators?

Compressor Room Operators must adhere to strict safety protocols, including wearing appropriate PPE, following lockout/tagout procedures, and being aware of potential hazards such as high pressure and electrical equipment.

What are the key responsibilities of a Compressor Room Operator?

Compressor Room Operators are responsible for operating, monitoring, maintaining, and troubleshooting compressors, ensuring optimal performance and safety while adhering to established procedures.