Are you a seasoned Computer Integrated Manufacturing Operator (CIM Operator) seeking a new career path? Discover our professionally built Computer Integrated Manufacturing Operator (CIM Operator) Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

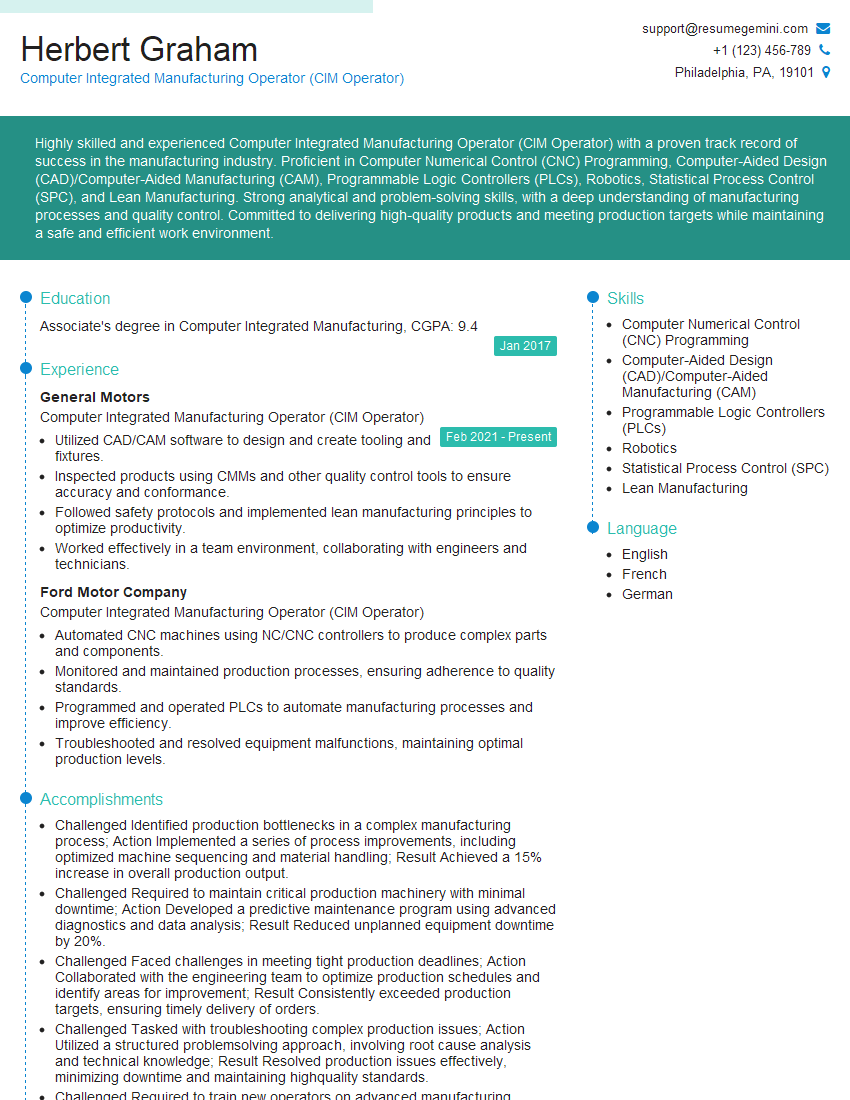

Herbert Graham

Computer Integrated Manufacturing Operator (CIM Operator)

Summary

Highly skilled and experienced Computer Integrated Manufacturing Operator (CIM Operator) with a proven track record of success in the manufacturing industry. Proficient in Computer Numerical Control (CNC) Programming, Computer-Aided Design (CAD)/Computer-Aided Manufacturing (CAM), Programmable Logic Controllers (PLCs), Robotics, Statistical Process Control (SPC), and Lean Manufacturing. Strong analytical and problem-solving skills, with a deep understanding of manufacturing processes and quality control. Committed to delivering high-quality products and meeting production targets while maintaining a safe and efficient work environment.

Education

Associate’s degree in Computer Integrated Manufacturing

January 2017

Skills

- Computer Numerical Control (CNC) Programming

- Computer-Aided Design (CAD)/Computer-Aided Manufacturing (CAM)

- Programmable Logic Controllers (PLCs)

- Robotics

- Statistical Process Control (SPC)

- Lean Manufacturing

Work Experience

Computer Integrated Manufacturing Operator (CIM Operator)

- Utilized CAD/CAM software to design and create tooling and fixtures.

- Inspected products using CMMs and other quality control tools to ensure accuracy and conformance.

- Followed safety protocols and implemented lean manufacturing principles to optimize productivity.

- Worked effectively in a team environment, collaborating with engineers and technicians.

Computer Integrated Manufacturing Operator (CIM Operator)

- Automated CNC machines using NC/CNC controllers to produce complex parts and components.

- Monitored and maintained production processes, ensuring adherence to quality standards.

- Programmed and operated PLCs to automate manufacturing processes and improve efficiency.

- Troubleshooted and resolved equipment malfunctions, maintaining optimal production levels.

Accomplishments

- Challenged Identified production bottlenecks in a complex manufacturing process; Action Implemented a series of process improvements, including optimized machine sequencing and material handling; Result Achieved a 15% increase in overall production output.

- Challenged Required to maintain critical production machinery with minimal downtime; Action Developed a predictive maintenance program using advanced diagnostics and data analysis; Result Reduced unplanned equipment downtime by 20%.

- Challenged Faced challenges in meeting tight production deadlines; Action Collaborated with the engineering team to optimize production schedules and identify areas for improvement; Result Consistently exceeded production targets, ensuring timely delivery of orders.

- Challenged Tasked with troubleshooting complex production issues; Action Utilized a structured problemsolving approach, involving root cause analysis and technical knowledge; Result Resolved production issues effectively, minimizing downtime and maintaining highquality standards.

- Challenged Required to train new operators on advanced manufacturing equipment; Action Developed and delivered comprehensive training programs, incorporating both theoretical and practical knowledge; Result Effectively onboarded new operators, ensuring proficiency and adherence to safety protocols.

Awards

- Recipient of the CIM Operator of the Year Award for outstanding performance in optimizing production efficiency.

- Recognized with the Safety Champion Award for consistently maintaining a safe and compliant work environment.

- Honored with the Excellence in Innovation Award for developing a novel automation solution that significantly reduced production costs.

Certificates

- Certified Manufacturing Technologist (CMfgT)

- Certified Manufacturing Engineer (CMfgE)

- Certified Lean Six Sigma Black Belt

- Certified Maintenance and Reliability Technician (CMRT)

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Computer Integrated Manufacturing Operator (CIM Operator)

- Highlight your technical skills and experience in CNC programming, CAD/CAM, and PLCs.

- Showcase your ability to work in a fast-paced, demanding environment and meet production targets.

- Demonstrate your understanding of manufacturing processes, quality control, and Lean Manufacturing principles.

- Provide specific examples of how you have used your skills to improve efficiency, reduce costs, or enhance product quality.

- Proofread your resume carefully before submitting it to potential employers.

Essential Experience Highlights for a Strong Computer Integrated Manufacturing Operator (CIM Operator) Resume

- Operate and monitor CNC machines and automated systems to produce precision parts and components.

- Program and troubleshoot CNC machines using industry-standard software.

- Set up and maintain automated production lines, ensuring optimal efficiency and quality.

- Monitor production processes using SPC techniques to identify and eliminate defects.

- Implement Lean Manufacturing principles to streamline processes and reduce waste.

- Collaborate with engineers and other team members to improve manufacturing processes and product quality.

Frequently Asked Questions (FAQ’s) For Computer Integrated Manufacturing Operator (CIM Operator)

What is the role of a Computer Integrated Manufacturing Operator?

A Computer Integrated Manufacturing Operator (CIM Operator) is responsible for operating and maintaining computer-controlled machines and automated systems in a manufacturing environment. They use their knowledge of CNC programming, CAD/CAM, PLCs, and other technologies to produce precision parts and components, set up and maintain production lines, and implement Lean Manufacturing principles to improve efficiency and quality.

What skills are required to be a successful CIM Operator?

Successful CIM Operators typically possess a combination of technical skills and experience in CNC programming, CAD/CAM, PLCs, Robotics, SPC, and Lean Manufacturing. They also have strong analytical and problem-solving skills, a deep understanding of manufacturing processes and quality control, and the ability to work in a fast-paced, demanding environment.

What are the career prospects for CIM Operators?

CIM Operators are in high demand in the manufacturing industry, as they play a critical role in the production of precision parts and components. With experience and additional training, CIM Operators can advance to supervisory or management positions, or specialize in areas such as CNC programming or robotics.

What is the average salary for a CIM Operator?

The average salary for a CIM Operator varies depending on factors such as experience, location, and industry. According to recent data, the average annual salary for CIM Operators in the United States is around $55,000.

What are the educational requirements for becoming a CIM Operator?

Most CIM Operators have an associate’s degree in Computer Integrated Manufacturing or a related field. Some employers may also require candidates to have a high school diploma or equivalent and relevant work experience.

Is certification required to become a CIM Operator?

Certification is not typically required to become a CIM Operator, but it can be beneficial for demonstrating your skills and knowledge to potential employers. There are several industry-recognized certifications available, such as the Certified Manufacturing Technologist (CMfgT) certification from the Society of Manufacturing Engineers (SME).