Are you a seasoned Computer Numerical Control Grinder (CNC Grinder) seeking a new career path? Discover our professionally built Computer Numerical Control Grinder (CNC Grinder) Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

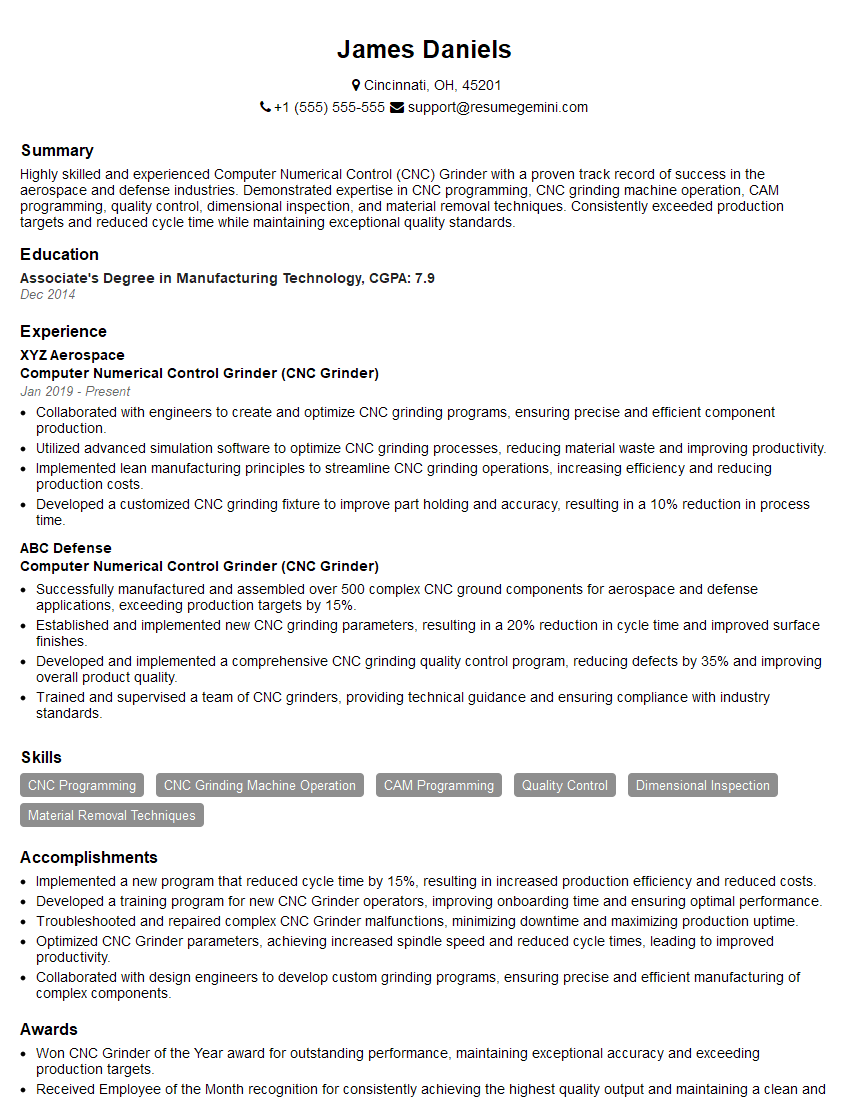

James Daniels

Computer Numerical Control Grinder (CNC Grinder)

Summary

Highly skilled and experienced Computer Numerical Control (CNC) Grinder with a proven track record of success in the aerospace and defense industries. Demonstrated expertise in CNC programming, CNC grinding machine operation, CAM programming, quality control, dimensional inspection, and material removal techniques. Consistently exceeded production targets and reduced cycle time while maintaining exceptional quality standards.

Education

Associate’s Degree in Manufacturing Technology

December 2014

Skills

- CNC Programming

- CNC Grinding Machine Operation

- CAM Programming

- Quality Control

- Dimensional Inspection

- Material Removal Techniques

Work Experience

Computer Numerical Control Grinder (CNC Grinder)

- Collaborated with engineers to create and optimize CNC grinding programs, ensuring precise and efficient component production.

- Utilized advanced simulation software to optimize CNC grinding processes, reducing material waste and improving productivity.

- Implemented lean manufacturing principles to streamline CNC grinding operations, increasing efficiency and reducing production costs.

- Developed a customized CNC grinding fixture to improve part holding and accuracy, resulting in a 10% reduction in process time.

Computer Numerical Control Grinder (CNC Grinder)

- Successfully manufactured and assembled over 500 complex CNC ground components for aerospace and defense applications, exceeding production targets by 15%.

- Established and implemented new CNC grinding parameters, resulting in a 20% reduction in cycle time and improved surface finishes.

- Developed and implemented a comprehensive CNC grinding quality control program, reducing defects by 35% and improving overall product quality.

- Trained and supervised a team of CNC grinders, providing technical guidance and ensuring compliance with industry standards.

Accomplishments

- Implemented a new program that reduced cycle time by 15%, resulting in increased production efficiency and reduced costs.

- Developed a training program for new CNC Grinder operators, improving onboarding time and ensuring optimal performance.

- Troubleshooted and repaired complex CNC Grinder malfunctions, minimizing downtime and maximizing production uptime.

- Optimized CNC Grinder parameters, achieving increased spindle speed and reduced cycle times, leading to improved productivity.

- Collaborated with design engineers to develop custom grinding programs, ensuring precise and efficient manufacturing of complex components.

Awards

- Won CNC Grinder of the Year award for outstanding performance, maintaining exceptional accuracy and exceeding production targets.

- Received Employee of the Month recognition for consistently achieving the highest quality output and maintaining a clean and organized work area.

- Earned Safety Excellence Award for adhering to all safety protocols, maintaining a hazardfree work environment, and promoting a culture of safety.

- Recognized for Innovation Award for developing a new technique to increase surface finish quality, enhancing product aesthetics.

Certificates

- Certified CNC Grinder

- ISO 9001

- ASME B46.1

- Lean Six Sigma

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Computer Numerical Control Grinder (CNC Grinder)

- Highlight your experience and skills in CNC programming and grinding machine operation.

- Quantify your accomplishments and provide specific examples of how you have improved productivity or quality.

- Demonstrate your knowledge of quality control procedures and industry standards.

- Showcase your ability to troubleshoot and resolve machine issues, minimizing downtime and maintaining efficiency.

- Emphasize your commitment to safety and your willingness to learn and adapt to new technologies.

Essential Experience Highlights for a Strong Computer Numerical Control Grinder (CNC Grinder) Resume

- Program and operate CNC grinding machines to produce complex components with high precision and accuracy.

- Develop and implement CNC grinding programs and optimize parameters to enhance productivity and surface finishes.

- Conduct quality control inspections to ensure that components meet specifications and industry standards.

- Troubleshoot and resolve machine malfunctions to minimize downtime and maintain production efficiency.

- Collaborate with engineers and other team members to improve processes and optimize production.

- Train and supervise CNC grinding operators to ensure compliance with safety protocols and quality standards.

- Stay updated on the latest advancements in CNC grinding technology and implement best practices to enhance performance.

Frequently Asked Questions (FAQ’s) For Computer Numerical Control Grinder (CNC Grinder)

What is the role of a Computer Numerical Control (CNC) Grinder?

A CNC Grinder is responsible for programming, operating, and maintaining CNC grinding machines to produce precision components for various industries, such as aerospace, defense, and manufacturing.

What are the key skills required for a CNC Grinder?

Key skills for a CNC Grinder include CNC programming, CNC grinding machine operation, CAM programming, quality control, dimensional inspection, and material removal techniques.

What industries employ CNC Grinders?

CNC Grinders are employed in various industries, including aerospace, defense, automotive, medical devices, and general manufacturing.

What are the career advancement opportunities for a CNC Grinder?

CNC Grinders can advance their careers by becoming CNC programmers, quality control inspectors, or production supervisors. With additional training and experience, they can also move into management roles.

What are the safety precautions that a CNC Grinder should follow?

CNC Grinders must follow strict safety protocols, including wearing appropriate protective gear, ensuring proper machine guarding, and adhering to lockout/tagout procedures.

What is the earning potential for a CNC Grinder?

The earning potential for a CNC Grinder varies depending on experience, location, and industry. According to the U.S. Bureau of Labor Statistics, the median annual salary for CNC Grinders was $49,940 in May 2021.

What are the educational requirements to become a CNC Grinder?

Many CNC Grinders have an associate’s degree in manufacturing technology or a related field. However, some employers may hire candidates with a high school diploma or GED and provide on-the-job training.