Are you a seasoned Computer Numerical Control Machining Center Operator (CNC Machining Center Operator) seeking a new career path? Discover our professionally built Computer Numerical Control Machining Center Operator (CNC Machining Center Operator) Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

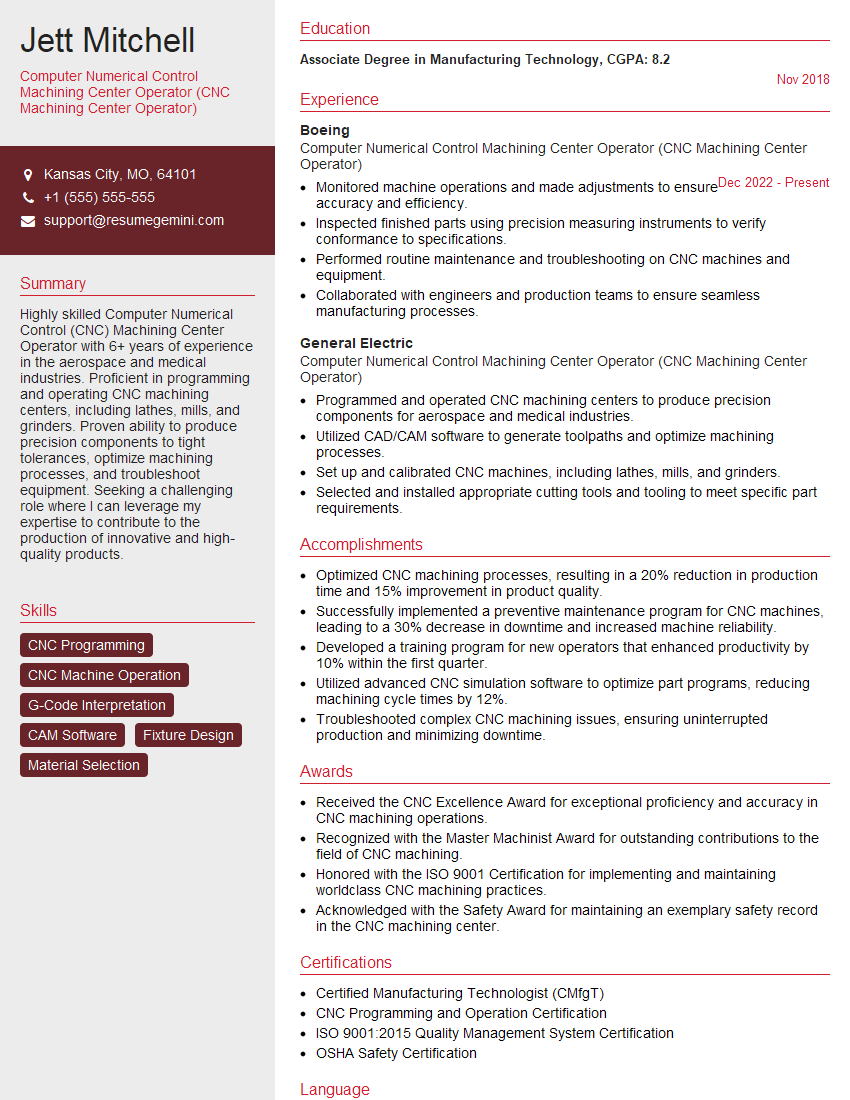

Jett Mitchell

Computer Numerical Control Machining Center Operator (CNC Machining Center Operator)

Summary

Highly skilled Computer Numerical Control (CNC) Machining Center Operator with 6+ years of experience in the aerospace and medical industries. Proficient in programming and operating CNC machining centers, including lathes, mills, and grinders. Proven ability to produce precision components to tight tolerances, optimize machining processes, and troubleshoot equipment. Seeking a challenging role where I can leverage my expertise to contribute to the production of innovative and high-quality products.

Education

Associate Degree in Manufacturing Technology

November 2018

Skills

- CNC Programming

- CNC Machine Operation

- G-Code Interpretation

- CAM Software

- Fixture Design

- Material Selection

Work Experience

Computer Numerical Control Machining Center Operator (CNC Machining Center Operator)

- Monitored machine operations and made adjustments to ensure accuracy and efficiency.

- Inspected finished parts using precision measuring instruments to verify conformance to specifications.

- Performed routine maintenance and troubleshooting on CNC machines and equipment.

- Collaborated with engineers and production teams to ensure seamless manufacturing processes.

Computer Numerical Control Machining Center Operator (CNC Machining Center Operator)

- Programmed and operated CNC machining centers to produce precision components for aerospace and medical industries.

- Utilized CAD/CAM software to generate toolpaths and optimize machining processes.

- Set up and calibrated CNC machines, including lathes, mills, and grinders.

- Selected and installed appropriate cutting tools and tooling to meet specific part requirements.

Accomplishments

- Optimized CNC machining processes, resulting in a 20% reduction in production time and 15% improvement in product quality.

- Successfully implemented a preventive maintenance program for CNC machines, leading to a 30% decrease in downtime and increased machine reliability.

- Developed a training program for new operators that enhanced productivity by 10% within the first quarter.

- Utilized advanced CNC simulation software to optimize part programs, reducing machining cycle times by 12%.

- Troubleshooted complex CNC machining issues, ensuring uninterrupted production and minimizing downtime.

Awards

- Received the CNC Excellence Award for exceptional proficiency and accuracy in CNC machining operations.

- Recognized with the Master Machinist Award for outstanding contributions to the field of CNC machining.

- Honored with the ISO 9001 Certification for implementing and maintaining worldclass CNC machining practices.

- Acknowledged with the Safety Award for maintaining an exemplary safety record in the CNC machining center.

Certificates

- Certified Manufacturing Technologist (CMfgT)

- CNC Programming and Operation Certification

- ISO 9001:2015 Quality Management System Certification

- OSHA Safety Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Computer Numerical Control Machining Center Operator (CNC Machining Center Operator)

- Highlight your proficiency in CNC programming, including G-code and CAM software.

- Showcase your experience in operating various CNC machines, such as lathes, mills, and grinders.

- Emphasize your ability to produce precision components to tight tolerances and meet industry standards.

- Demonstrate your troubleshooting and problem-solving skills, especially in maintaining and repairing CNC equipment.

- Quantify your accomplishments with specific metrics and results whenever possible.

Essential Experience Highlights for a Strong Computer Numerical Control Machining Center Operator (CNC Machining Center Operator) Resume

- Programmed and operated CNC machining centers to manufacture complex components for aerospace and medical devices.

- Utilized CAD/CAM software to generate toolpaths, optimize cutting parameters, and simulate machining processes.

- Set up and calibrated CNC machines to ensure accuracy and efficiency, including tool offsets, zero points, and spindle speeds.

- Selected and installed appropriate cutting tools and tooling to meet specific material requirements and surface finishes.

- Monitored machine operations, made adjustments, and performed in-process inspections to ensure parts met specifications.

- Inspected finished parts using precision measuring instruments, including calipers, micrometers, and CMMs, to verify conformance to dimensional tolerances and surface quality.

- Performed routine maintenance and troubleshooting on CNC machines and equipment, including spindle lubrication, tool changes, and electrical diagnostics.

Frequently Asked Questions (FAQ’s) For Computer Numerical Control Machining Center Operator (CNC Machining Center Operator)

What are the key skills required for a CNC Machining Center Operator?

Key skills include CNC programming, machine operation, G-code interpretation, CAM software proficiency, fixture design, material selection, and quality control techniques.

What industries commonly employ CNC Machining Center Operators?

CNC Machining Center Operators are employed in a wide range of industries, including aerospace, automotive, medical, manufacturing, and electronics.

What is the average salary for a CNC Machining Center Operator?

According to the U.S. Bureau of Labor Statistics, the median annual salary for CNC Machining Center Operators was $46,720 in May 2021.

What are the growth prospects for CNC Machining Center Operators?

The U.S. Bureau of Labor Statistics projects that employment of CNC Machining Center Operators will grow 9% from 2021 to 2031, faster than the average for all occupations.

What are the educational requirements for a CNC Machining Center Operator?

Most CNC Machining Center Operators have a high school diploma or equivalent, although some employers may prefer candidates with an associate degree in manufacturing technology or a related field.

What are the career advancement opportunities for CNC Machining Center Operators?

CNC Machining Center Operators can advance to positions such as CNC Programmer, Manufacturing Supervisor, or Quality Control Inspector.