Are you a seasoned Computer Numerical Control Operator (CNC Operator) seeking a new career path? Discover our professionally built Computer Numerical Control Operator (CNC Operator) Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

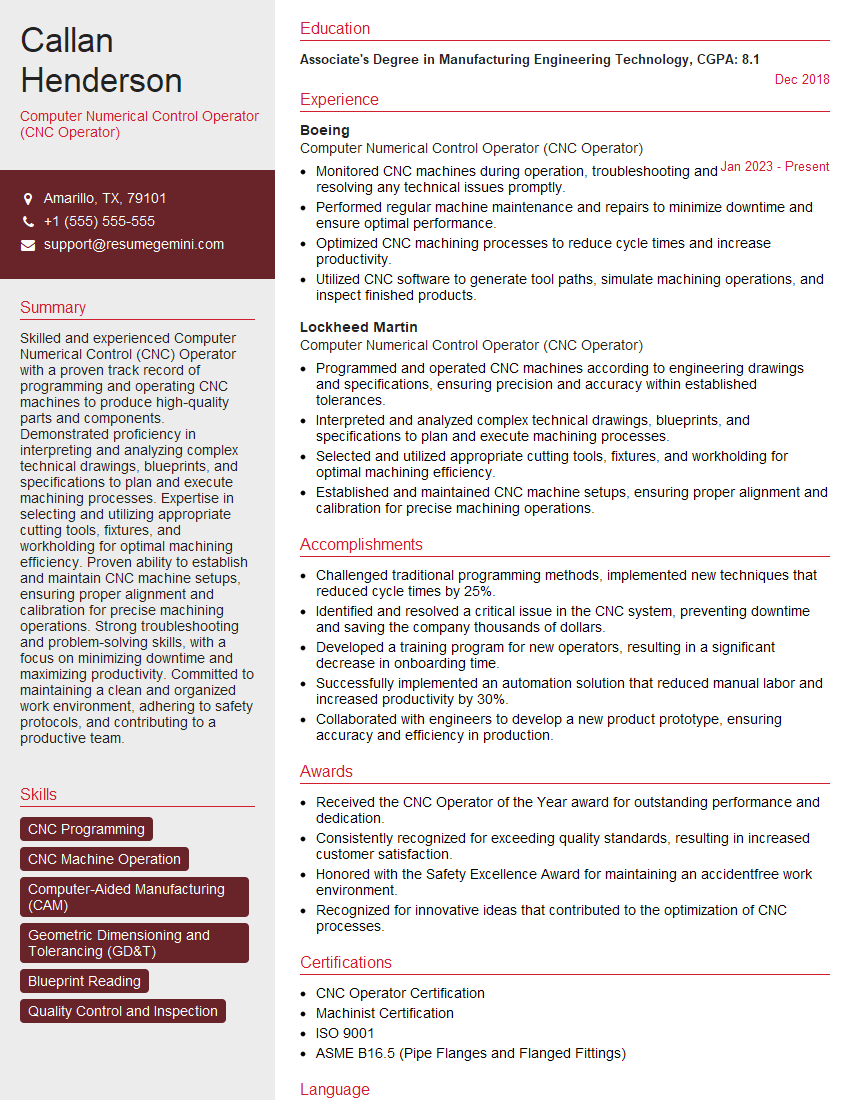

Callan Henderson

Computer Numerical Control Operator (CNC Operator)

Summary

Skilled and experienced Computer Numerical Control (CNC) Operator with a proven track record of programming and operating CNC machines to produce high-quality parts and components. Demonstrated proficiency in interpreting and analyzing complex technical drawings, blueprints, and specifications to plan and execute machining processes. Expertise in selecting and utilizing appropriate cutting tools, fixtures, and workholding for optimal machining efficiency. Proven ability to establish and maintain CNC machine setups, ensuring proper alignment and calibration for precise machining operations. Strong troubleshooting and problem-solving skills, with a focus on minimizing downtime and maximizing productivity. Committed to maintaining a clean and organized work environment, adhering to safety protocols, and contributing to a productive team.

Education

Associate’s Degree in Manufacturing Engineering Technology

December 2018

Skills

- CNC Programming

- CNC Machine Operation

- Computer-Aided Manufacturing (CAM)

- Geometric Dimensioning and Tolerancing (GD&T)

- Blueprint Reading

- Quality Control and Inspection

Work Experience

Computer Numerical Control Operator (CNC Operator)

- Monitored CNC machines during operation, troubleshooting and resolving any technical issues promptly.

- Performed regular machine maintenance and repairs to minimize downtime and ensure optimal performance.

- Optimized CNC machining processes to reduce cycle times and increase productivity.

- Utilized CNC software to generate tool paths, simulate machining operations, and inspect finished products.

Computer Numerical Control Operator (CNC Operator)

- Programmed and operated CNC machines according to engineering drawings and specifications, ensuring precision and accuracy within established tolerances.

- Interpreted and analyzed complex technical drawings, blueprints, and specifications to plan and execute machining processes.

- Selected and utilized appropriate cutting tools, fixtures, and workholding for optimal machining efficiency.

- Established and maintained CNC machine setups, ensuring proper alignment and calibration for precise machining operations.

Accomplishments

- Challenged traditional programming methods, implemented new techniques that reduced cycle times by 25%.

- Identified and resolved a critical issue in the CNC system, preventing downtime and saving the company thousands of dollars.

- Developed a training program for new operators, resulting in a significant decrease in onboarding time.

- Successfully implemented an automation solution that reduced manual labor and increased productivity by 30%.

- Collaborated with engineers to develop a new product prototype, ensuring accuracy and efficiency in production.

Awards

- Received the CNC Operator of the Year award for outstanding performance and dedication.

- Consistently recognized for exceeding quality standards, resulting in increased customer satisfaction.

- Honored with the Safety Excellence Award for maintaining an accidentfree work environment.

- Recognized for innovative ideas that contributed to the optimization of CNC processes.

Certificates

- CNC Operator Certification

- Machinist Certification

- ISO 9001

- ASME B16.5 (Pipe Flanges and Flanged Fittings)

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Computer Numerical Control Operator (CNC Operator)

- Highlight your skills and experience in CNC programming and operation. This is the core competency for this role, so make sure to emphasize your proficiency in using CNC machines and software.

- Demonstrate your knowledge of GD&T and blueprint reading. These are essential skills for CNC Operators, as they allow you to interpret technical drawings and specifications accurately.

- Showcase your problem-solving and troubleshooting abilities. CNC machines can be complex, and unexpected issues can arise. Highlight your ability to identify and resolve problems quickly and efficiently.

- Emphasize your commitment to quality and accuracy. CNC Operators must be able to produce high-quality parts and components that meet the required specifications.

- Include any certifications or training that you have received. This shows that you are committed to your professional development and staying up-to-date with the latest industry trends.

Essential Experience Highlights for a Strong Computer Numerical Control Operator (CNC Operator) Resume

- Program and operate CNC machines according to engineering drawings and specifications, ensuring precision and accuracy within established tolerances.

- Interpret and analyze complex technical drawings, blueprints, and specifications to plan and execute machining processes.

- Select and utilize appropriate cutting tools, fixtures, and workholding for optimal machining efficiency.

- Establish and maintain CNC machine setups, ensuring proper alignment and calibration for precise machining operations.

- Monitor CNC machines during operation, troubleshooting and resolving any technical issues promptly.

- Perform regular machine maintenance and repairs to minimize downtime and ensure optimal performance.

- Optimize CNC machining processes to reduce cycle times and increase productivity.

- Utilize CNC software to generate tool paths, simulate machining operations, and inspect finished products.

Frequently Asked Questions (FAQ’s) For Computer Numerical Control Operator (CNC Operator)

What is a CNC Operator?

A CNC Operator is a skilled professional who programs and operates Computer Numerical Control (CNC) machines to produce precision parts and components. They use CNC software to create tool paths, set up and calibrate machines, and monitor operations to ensure accuracy and efficiency.

What are the key skills required for a CNC Operator?

Key skills for a CNC Operator include CNC programming and operation, computer-aided manufacturing (CAM), geometric dimensioning and tolerancing (GD&T), blueprint reading, quality control and inspection, and troubleshooting.

What industries employ CNC Operators?

CNC Operators are employed in various industries, including manufacturing, aerospace, automotive, medical, and electronics. They work in production facilities, machine shops, and research and development laboratories.

What is the job outlook for CNC Operators?

The job outlook for CNC Operators is expected to grow in the coming years due to the increasing demand for precision-machined parts and components in various industries.

What is the average salary for a CNC Operator?

The average salary for a CNC Operator can vary depending on experience, location, and industry. According to the U.S. Bureau of Labor Statistics, the median annual salary for Computer-Controlled Machine Tool Operators, including CNC Operators, was $48,080 in May 2021.

What are the career advancement opportunities for CNC Operators?

CNC Operators can advance their careers by becoming CNC programmers, manufacturing engineers, or quality control inspectors. They can also specialize in a particular industry, such as aerospace or medical manufacturing.

How can I become a CNC Operator?

To become a CNC Operator, you can complete an associate’s degree or certificate program in manufacturing technology or a related field. Some employers may also provide on-the-job training for qualified candidates.

What is the difference between a CNC Operator and a machinist?

A CNC Operator primarily operates CNC machines, while a machinist has a broader range of skills and responsibilities. Machinists can perform manual machining operations, set up and operate CNC machines, and work with various materials and tools.