Are you a seasoned Computer Numerical Control Turning Machine Operator (CNC Turning Machine Operator) seeking a new career path? Discover our professionally built Computer Numerical Control Turning Machine Operator (CNC Turning Machine Operator) Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

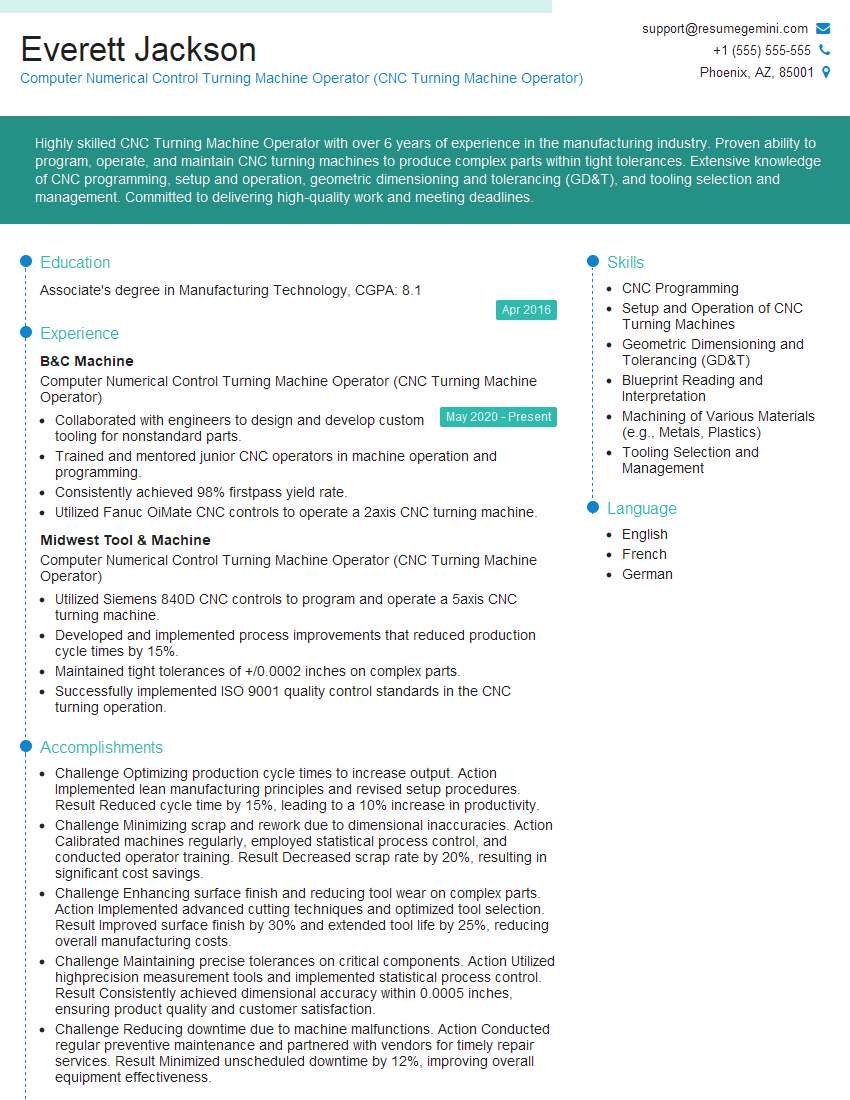

Everett Jackson

Computer Numerical Control Turning Machine Operator (CNC Turning Machine Operator)

Summary

Highly skilled CNC Turning Machine Operator with over 6 years of experience in the manufacturing industry. Proven ability to program, operate, and maintain CNC turning machines to produce complex parts within tight tolerances. Extensive knowledge of CNC programming, setup and operation, geometric dimensioning and tolerancing (GD&T), and tooling selection and management. Committed to delivering high-quality work and meeting deadlines.

Education

Associate’s degree in Manufacturing Technology

April 2016

Skills

- CNC Programming

- Setup and Operation of CNC Turning Machines

- Geometric Dimensioning and Tolerancing (GD&T)

- Blueprint Reading and Interpretation

- Machining of Various Materials (e.g., Metals, Plastics)

- Tooling Selection and Management

Work Experience

Computer Numerical Control Turning Machine Operator (CNC Turning Machine Operator)

- Collaborated with engineers to design and develop custom tooling for nonstandard parts.

- Trained and mentored junior CNC operators in machine operation and programming.

- Consistently achieved 98% firstpass yield rate.

- Utilized Fanuc OiMate CNC controls to operate a 2axis CNC turning machine.

Computer Numerical Control Turning Machine Operator (CNC Turning Machine Operator)

- Utilized Siemens 840D CNC controls to program and operate a 5axis CNC turning machine.

- Developed and implemented process improvements that reduced production cycle times by 15%.

- Maintained tight tolerances of +/0.0002 inches on complex parts.

- Successfully implemented ISO 9001 quality control standards in the CNC turning operation.

Accomplishments

- Challenge Optimizing production cycle times to increase output. Action Implemented lean manufacturing principles and revised setup procedures. Result Reduced cycle time by 15%, leading to a 10% increase in productivity.

- Challenge Minimizing scrap and rework due to dimensional inaccuracies. Action Calibrated machines regularly, employed statistical process control, and conducted operator training. Result Decreased scrap rate by 20%, resulting in significant cost savings.

- Challenge Enhancing surface finish and reducing tool wear on complex parts. Action Implemented advanced cutting techniques and optimized tool selection. Result Improved surface finish by 30% and extended tool life by 25%, reducing overall manufacturing costs.

- Challenge Maintaining precise tolerances on critical components. Action Utilized highprecision measurement tools and implemented statistical process control. Result Consistently achieved dimensional accuracy within 0.0005 inches, ensuring product quality and customer satisfaction.

- Challenge Reducing downtime due to machine malfunctions. Action Conducted regular preventive maintenance and partnered with vendors for timely repair services. Result Minimized unscheduled downtime by 12%, improving overall equipment effectiveness.

Awards

- Recognized for exceeding production quotas, maintaining highquality standards, and innovative problemsolving.

- Awarded for outstanding contribution to the implementation of a new CNC turning system, resulting in increased efficiency.

- Received recognition for maintaining a spotless safety record and adhering to all safety protocols.

Certificates

- Certified Manufacturing Technologist (CMfgT)

- National Institute for Metalworking Skills (NIMS) Credentials

- American Society for Quality (ASQ) Certifications

- CNC Operator Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Computer Numerical Control Turning Machine Operator (CNC Turning Machine Operator)

- Highlight your experience with specific CNC turning machines and controls, such as Siemens 840D and Fanuc OiMate.

- Quantify your accomplishments with specific metrics, such as reducing production cycle times by 15% or achieving a 98% first-pass yield rate.

- Emphasize your knowledge of GD&T and your ability to read and interpret blueprints.

- Showcase your ability to work independently and as part of a team.

Essential Experience Highlights for a Strong Computer Numerical Control Turning Machine Operator (CNC Turning Machine Operator) Resume

- Programmed and operated CNC turning machines to produce complex parts within tight tolerances of +/0.0002 inches.

- Developed and implemented process improvements that reduced production cycle times by 15%.

- Utilized Siemens 840D CNC controls to program and operate a 5-axis CNC turning machine.

- Collaborated with engineers to design and develop custom tooling for nonstandard parts.

- Maintained tight tolerances of +/0.0002 inches on complex parts.

- Successfully implemented ISO 9001 quality control standards in the CNC turning operation.

Frequently Asked Questions (FAQ’s) For Computer Numerical Control Turning Machine Operator (CNC Turning Machine Operator)

What is the role of a CNC Turning Machine Operator?

A CNC Turning Machine Operator is responsible for programming, operating, and maintaining CNC turning machines to produce complex parts within tight tolerances.

What are the key skills required for a CNC Turning Machine Operator?

Key skills for a CNC Turning Machine Operator include CNC programming, setup and operation, geometric dimensioning and tolerancing (GD&T), blueprint reading and interpretation, machining of various materials, and tooling selection and management.

What are the career prospects for a CNC Turning Machine Operator?

CNC Turning Machine Operators are in high demand due to the increasing use of CNC machines in the manufacturing industry. With experience, CNC Turning Machine Operators can advance to positions such as CNC Programmer, CNC Machinist, or Manufacturing Engineer.

What is the average salary for a CNC Turning Machine Operator?

The average salary for a CNC Turning Machine Operator varies depending on experience, location, and industry. According to Indeed, the average salary for a CNC Turning Machine Operator in the United States is $24.50 per hour.

What are the educational requirements for a CNC Turning Machine Operator?

Most CNC Turning Machine Operators have an associate’s degree in Manufacturing Technology or a related field. However, some employers may hire candidates with a high school diploma or equivalent and relevant experience.