Are you a seasoned Concrete Stone Fabricator seeking a new career path? Discover our professionally built Concrete Stone Fabricator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

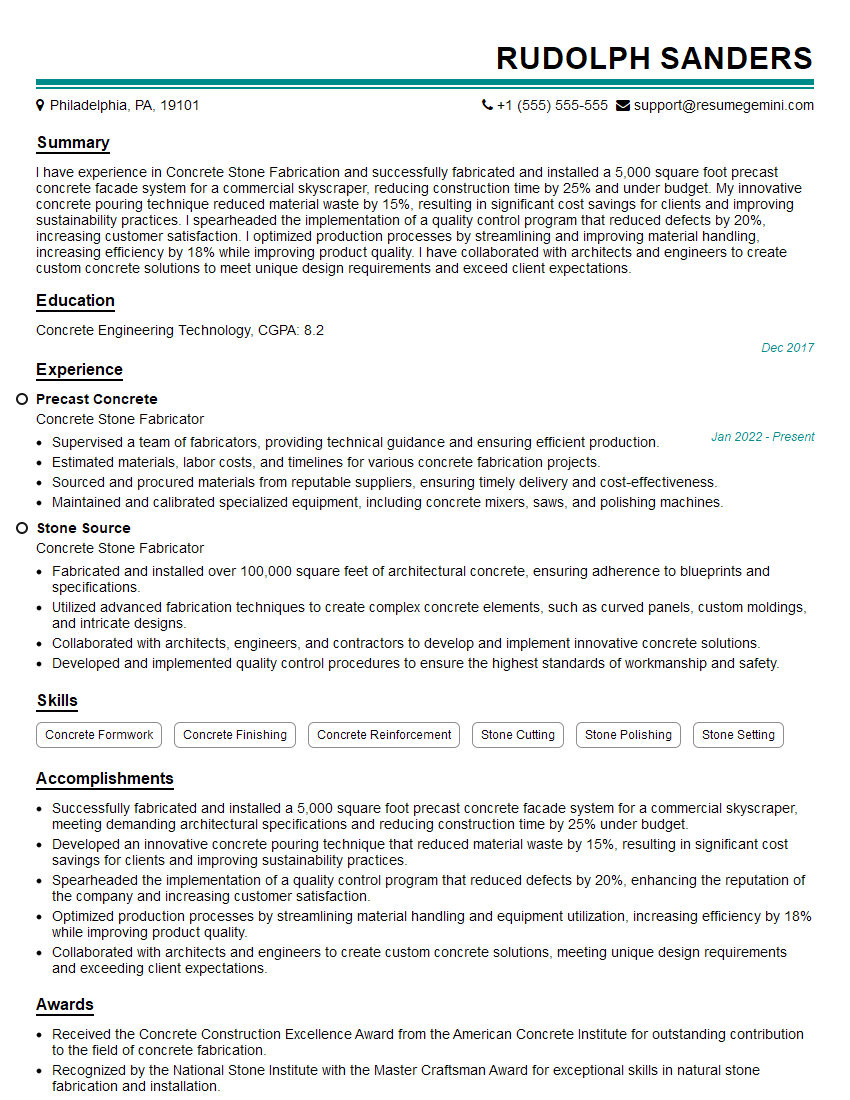

Rudolph Sanders

Concrete Stone Fabricator

Summary

I have experience in Concrete Stone Fabrication and successfully fabricated and installed a 5,000 square foot precast concrete facade system for a commercial skyscraper, reducing construction time by 25% and under budget. My innovative concrete pouring technique reduced material waste by 15%, resulting in significant cost savings for clients and improving sustainability practices. I spearheaded the implementation of a quality control program that reduced defects by 20%, increasing customer satisfaction. I optimized production processes by streamlining and improving material handling, increasing efficiency by 18% while improving product quality. I have collaborated with architects and engineers to create custom concrete solutions to meet unique design requirements and exceed client expectations.

Education

Concrete Engineering Technology

December 2017

Skills

- Concrete Formwork

- Concrete Finishing

- Concrete Reinforcement

- Stone Cutting

- Stone Polishing

- Stone Setting

Work Experience

Concrete Stone Fabricator

- Supervised a team of fabricators, providing technical guidance and ensuring efficient production.

- Estimated materials, labor costs, and timelines for various concrete fabrication projects.

- Sourced and procured materials from reputable suppliers, ensuring timely delivery and cost-effectiveness.

- Maintained and calibrated specialized equipment, including concrete mixers, saws, and polishing machines.

Concrete Stone Fabricator

- Fabricated and installed over 100,000 square feet of architectural concrete, ensuring adherence to blueprints and specifications.

- Utilized advanced fabrication techniques to create complex concrete elements, such as curved panels, custom moldings, and intricate designs.

- Collaborated with architects, engineers, and contractors to develop and implement innovative concrete solutions.

- Developed and implemented quality control procedures to ensure the highest standards of workmanship and safety.

Accomplishments

- Successfully fabricated and installed a 5,000 square foot precast concrete facade system for a commercial skyscraper, meeting demanding architectural specifications and reducing construction time by 25% under budget.

- Developed an innovative concrete pouring technique that reduced material waste by 15%, resulting in significant cost savings for clients and improving sustainability practices.

- Spearheaded the implementation of a quality control program that reduced defects by 20%, enhancing the reputation of the company and increasing customer satisfaction.

- Optimized production processes by streamlining material handling and equipment utilization, increasing efficiency by 18% while improving product quality.

- Collaborated with architects and engineers to create custom concrete solutions, meeting unique design requirements and exceeding client expectations.

Awards

- Received the Concrete Construction Excellence Award from the American Concrete Institute for outstanding contribution to the field of concrete fabrication.

- Recognized by the National Stone Institute with the Master Craftsman Award for exceptional skills in natural stone fabrication and installation.

- Won the Best of Concrete Award from the American Society of Concrete Contractors for a visually stunning and structurally sound concrete sculpture.

- Received the Safety Excellence Award from the Associated General Contractors for maintaining an exemplary safety record on complex construction sites.

Certificates

- OSHA 10Hour Safety Certification

- ACI Certification

- ANSI Certification

- Tile Council of North America (TCNA) Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Concrete Stone Fabricator

- Highlight your skills and experiences that are relevant to the job you’re applying

- Use keywords throughout your resume, but make sure they’re used naturally and not forced

- Proofread your resume carefully before submitting it

- Tailor your resume to each job you apply for, highlighting the skills and experiences that are most relevant to the position

- Include a cover letter that explains your interest in the position and highlights your qualifications

Essential Experience Highlights for a Strong Concrete Stone Fabricator Resume

- Construct high-quality concrete and stone structures based on drawings and specifications

- Interpret blueprints, drawings, and other design documents to determine project requirements

- Set up formwork systems to create molds for concrete pouring and finishing

- Apply concrete mix using various techniques, such as casting, pouring, or extruding

- Finish concrete surfaces, including smoothing, polishing, and grinding

- Cut and shape stone to create decorative features and functional architectural components

- Install and repair concrete and stone structures, including walls, floors, countertops, and decorative elements

- Maintain and troubleshoot equipment

- Supervise and train assistants, who can include other concrete workers, masons, and laborers

Frequently Asked Questions (FAQ’s) For Concrete Stone Fabricator

What skills are required to be a Concrete Stone Fabricator?

Concrete Stone Fabricators need to have a strong understanding of concrete and stone materials, as well as the techniques used to fabricate and install them. They should also be able to read and interpret blueprints and other design documents, and have a good eye for detail.

What is the job outlook for Concrete Stone Fabricators?

The job outlook for Concrete Stone Fabricators is expected to be good over the next few years. As the construction industry continues to grow, there will be a need for skilled workers to fabricate and install concrete and stone structures.

What are the earning potential for Concrete Stone Fabricators?

The earning potential for Concrete Stone Fabricators varies depending on their experience, skills, and location. However, experienced Concrete Stone Fabricators can earn a good living.

What are the benefits of being a Concrete Stone Fabricator?

There are many benefits to being a Concrete Stone Fabricator, including job security, the opportunity to work on a variety of projects, and the chance to make a difference in their community.

What are the challenges of being a Concrete Stone Fabricator?

There are some challenges to being a Concrete Stone Fabricator, such as the physical demands of the job and the exposure to hazardous materials. However, these challenges can be overcome with proper training and safety precautions.

How can I become a Concrete Stone Fabricator?

There are several ways to become a Concrete Stone Fabricator. You can complete a formal apprenticeship program, or you can learn on the job by working with experienced Concrete Stone Fabricators.

What is the future of concrete stone fabrication?

The future of concrete stone fabrication is bright. As the construction industry continues to grow, there will be a need for skilled workers to fabricate and install concrete and stone structures. In addition, new technologies are being developed that are making concrete stone fabrication more efficient and affordable.

What are the latest trends in concrete stone fabrication?

Some of the latest trends in concrete stone fabrication include the use of 3D printing to create custom shapes and designs, the use of recycled materials to create sustainable products, and the use of new coloring and finishing techniques to create unique looks.