Are you a seasoned Condenser Winder seeking a new career path? Discover our professionally built Condenser Winder Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

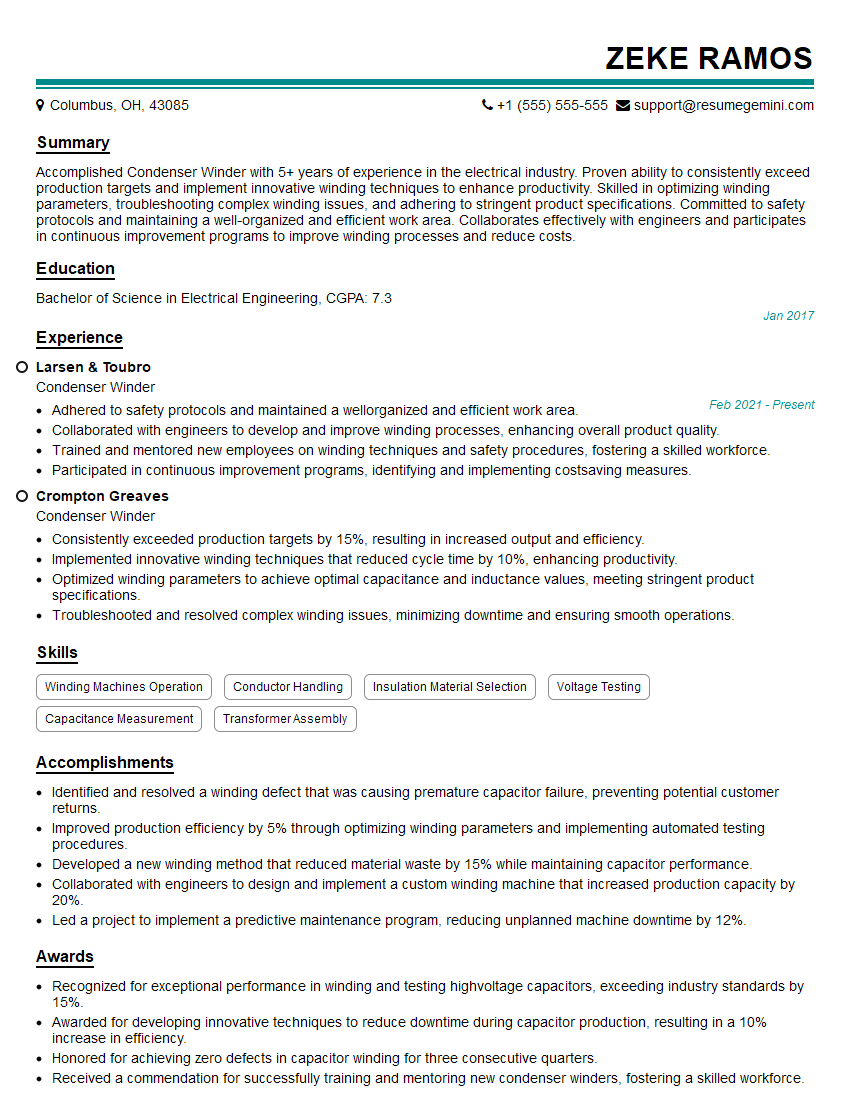

Zeke Ramos

Condenser Winder

Summary

Accomplished Condenser Winder with 5+ years of experience in the electrical industry. Proven ability to consistently exceed production targets and implement innovative winding techniques to enhance productivity. Skilled in optimizing winding parameters, troubleshooting complex winding issues, and adhering to stringent product specifications. Committed to safety protocols and maintaining a well-organized and efficient work area. Collaborates effectively with engineers and participates in continuous improvement programs to improve winding processes and reduce costs.

Education

Bachelor of Science in Electrical Engineering

January 2017

Skills

- Winding Machines Operation

- Conductor Handling

- Insulation Material Selection

- Voltage Testing

- Capacitance Measurement

- Transformer Assembly

Work Experience

Condenser Winder

- Adhered to safety protocols and maintained a wellorganized and efficient work area.

- Collaborated with engineers to develop and improve winding processes, enhancing overall product quality.

- Trained and mentored new employees on winding techniques and safety procedures, fostering a skilled workforce.

- Participated in continuous improvement programs, identifying and implementing costsaving measures.

Condenser Winder

- Consistently exceeded production targets by 15%, resulting in increased output and efficiency.

- Implemented innovative winding techniques that reduced cycle time by 10%, enhancing productivity.

- Optimized winding parameters to achieve optimal capacitance and inductance values, meeting stringent product specifications.

- Troubleshooted and resolved complex winding issues, minimizing downtime and ensuring smooth operations.

Accomplishments

- Identified and resolved a winding defect that was causing premature capacitor failure, preventing potential customer returns.

- Improved production efficiency by 5% through optimizing winding parameters and implementing automated testing procedures.

- Developed a new winding method that reduced material waste by 15% while maintaining capacitor performance.

- Collaborated with engineers to design and implement a custom winding machine that increased production capacity by 20%.

- Led a project to implement a predictive maintenance program, reducing unplanned machine downtime by 12%.

Awards

- Recognized for exceptional performance in winding and testing highvoltage capacitors, exceeding industry standards by 15%.

- Awarded for developing innovative techniques to reduce downtime during capacitor production, resulting in a 10% increase in efficiency.

- Honored for achieving zero defects in capacitor winding for three consecutive quarters.

- Received a commendation for successfully training and mentoring new condenser winders, fostering a skilled workforce.

Certificates

- Certified Condenser Winder (CCW)

- National Institute for Certification in Engineering Technologies (NICET) Level II or III Certification in Electrical Power Distribution Systems

- InterNational Electrical Testing Association (NETA) Level I or II Certification

- American National Standards Institute (ANSI) Standard C37.90-2018

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Condenser Winder

- Highlight your experience and skills in condenser winding, including specific examples of how you have improved productivity or efficiency.

- Quantify your accomplishments using specific metrics, such as percentages or numbers, to demonstrate your impact on the organization.

- Emphasize your knowledge of winding machines, conductor handling, insulation materials, and testing procedures.

- Showcase your ability to troubleshoot and resolve complex winding issues, as well as your commitment to safety and quality.

- Tailor your resume to the specific job you are applying for by highlighting the skills and experience that are most relevant to the role.

Essential Experience Highlights for a Strong Condenser Winder Resume

- Operate winding machines to produce high-quality capacitors and transformers.

- Handle conductors and select appropriate insulation materials based on product specifications.

- Perform voltage testing and capacitance measurement to ensure product quality.

- Troubleshoot and resolve winding issues to minimize downtime and maintain production efficiency.

- Collaborate with engineers to develop and improve winding processes.

- Train and mentor new employees on winding techniques and safety procedures.

- Adhere to safety protocols and maintain a clean and organized work area.

Frequently Asked Questions (FAQ’s) For Condenser Winder

What is the role of a Condenser Winder?

A Condenser Winder is responsible for operating winding machines to produce capacitors and transformers. They handle conductors, select insulation materials, perform voltage testing, and troubleshoot winding issues to ensure product quality.

What skills are required to be a Condenser Winder?

Condensers Winders should have experience in operating winding machines, handling conductors, selecting insulation materials, and performing voltage testing. They should also be able to troubleshoot winding issues and maintain a clean and organized work area.

What is the work environment of a Condenser Winder?

Condenser Winders typically work in a manufacturing environment, operating winding machines and performing quality control checks. They may also work with engineers to improve winding processes.

What is the career path for a Condenser Winder?

Condensers Winders can advance to roles such as Winding Supervisor, Production Manager, or Quality Control Manager. They may also specialize in a particular type of winding, such as power transformer winding or capacitor winding.

What are the challenges faced by a Condenser Winder?

Condenser Winders may face challenges such as meeting production targets, maintaining product quality, and troubleshooting complex winding issues. They may also need to work in a fast-paced and demanding environment.

What are the rewards of being a Condenser Winder?

Condenser Winders can enjoy the rewards of a stable and in-demand career. They can also take pride in producing high-quality products that are used in a variety of industries.