Are you a seasoned Construction Equipment Mechanic seeking a new career path? Discover our professionally built Construction Equipment Mechanic Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

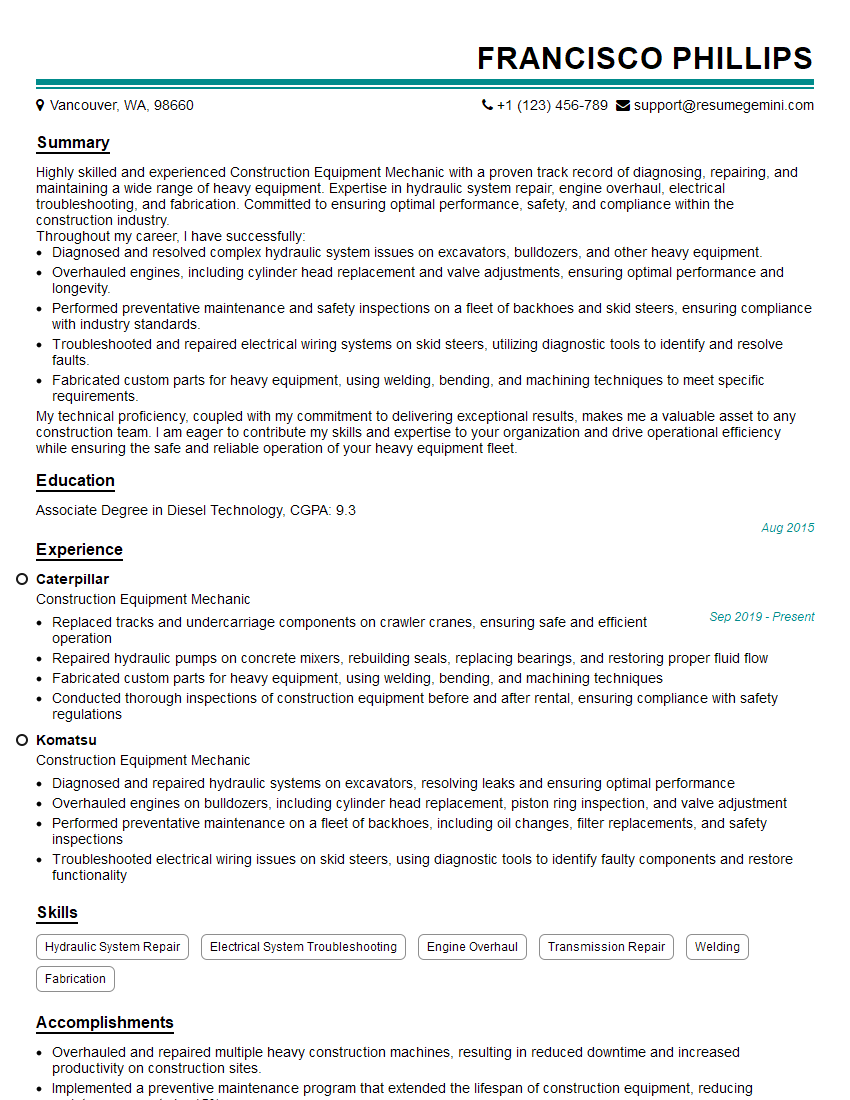

Francisco Phillips

Construction Equipment Mechanic

Summary

Highly skilled and experienced Construction Equipment Mechanic with a proven track record of diagnosing, repairing, and maintaining a wide range of heavy equipment. Expertise in hydraulic system repair, engine overhaul, electrical troubleshooting, and fabrication. Committed to ensuring optimal performance, safety, and compliance within the construction industry.

Throughout my career, I have successfully:

- Diagnosed and resolved complex hydraulic system issues on excavators, bulldozers, and other heavy equipment.

- Overhauled engines, including cylinder head replacement and valve adjustments, ensuring optimal performance and longevity.

- Performed preventative maintenance and safety inspections on a fleet of backhoes and skid steers, ensuring compliance with industry standards.

- Troubleshooted and repaired electrical wiring systems on skid steers, utilizing diagnostic tools to identify and resolve faults.

- Fabricated custom parts for heavy equipment, using welding, bending, and machining techniques to meet specific requirements.

My technical proficiency, coupled with my commitment to delivering exceptional results, makes me a valuable asset to any construction team. I am eager to contribute my skills and expertise to your organization and drive operational efficiency while ensuring the safe and reliable operation of your heavy equipment fleet.

Education

Associate Degree in Diesel Technology

August 2015

Skills

- Hydraulic System Repair

- Electrical System Troubleshooting

- Engine Overhaul

- Transmission Repair

- Welding

- Fabrication

Work Experience

Construction Equipment Mechanic

- Replaced tracks and undercarriage components on crawler cranes, ensuring safe and efficient operation

- Repaired hydraulic pumps on concrete mixers, rebuilding seals, replacing bearings, and restoring proper fluid flow

- Fabricated custom parts for heavy equipment, using welding, bending, and machining techniques

- Conducted thorough inspections of construction equipment before and after rental, ensuring compliance with safety regulations

Construction Equipment Mechanic

- Diagnosed and repaired hydraulic systems on excavators, resolving leaks and ensuring optimal performance

- Overhauled engines on bulldozers, including cylinder head replacement, piston ring inspection, and valve adjustment

- Performed preventative maintenance on a fleet of backhoes, including oil changes, filter replacements, and safety inspections

- Troubleshooted electrical wiring issues on skid steers, using diagnostic tools to identify faulty components and restore functionality

Accomplishments

- Overhauled and repaired multiple heavy construction machines, resulting in reduced downtime and increased productivity on construction sites.

- Implemented a preventive maintenance program that extended the lifespan of construction equipment, reducing maintenance costs by 15%.

- Troubleshooted and resolved complex malfunctions in hydraulic systems, ensuring optimal equipment performance and job site safety.

- Trained and mentored junior mechanics, fostering a skilled and efficient team for equipment maintenance and repair tasks.

- Developed and implemented innovative techniques to optimize construction equipment performance, resulting in increased productivity.

Awards

- Recognized with the annual company award for outstanding performance in construction equipment maintenance.

- Awarded certification for expertise in heavy equipment diagnostics and repair by a leading industry organization.

- Received accolades for consistently meeting and exceeding safety standards in equipment operation and maintenance.

Certificates

- ASE Master Technician

- Heavy Equipment Mechanic Certification

- Hydraulics Technician Certification

- Electrical Technician Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Construction Equipment Mechanic

- Highlight your technical skills and expertise in hydraulic systems, engine repair, and electrical troubleshooting.

- Quantify your accomplishments and provide specific examples of how you have contributed to operational efficiency and cost savings.

- Showcase your problem-solving abilities and provide instances where you have successfully diagnosed and resolved complex equipment issues.

- Demonstrate your commitment to safety and compliance by emphasizing your adherence to industry regulations and manufacturer guidelines.

Essential Experience Highlights for a Strong Construction Equipment Mechanic Resume

- Diagnose and repair hydraulic system faults, including leaks, pressure issues, and component failures.

- Overhaul engines, including cylinder head replacement, piston ring inspection, and valve adjustment, to restore optimal performance.

- Perform preventative maintenance and safety inspections on construction equipment, ensuring compliance with industry regulations and manufacturer recommendations.

- Troubleshoot and resolve electrical wiring issues, using diagnostic tools to identify faulty components and restore functionality.

- Fabricate custom parts for heavy equipment, using welding, bending, and machining techniques, to meet specific requirements and enhance equipment performance.

- Collaborate with engineers and other technicians to identify and implement solutions for complex equipment issues.

- Maintain a clean and organized work area, ensuring adherence to safety protocols and promoting efficient workflow.

Frequently Asked Questions (FAQ’s) For Construction Equipment Mechanic

What are the essential skills required for a Construction Equipment Mechanic?

Essential skills for a Construction Equipment Mechanic include proficiency in hydraulic system repair, engine overhaul, electrical troubleshooting, welding, and fabrication. Additionally, a strong understanding of diesel engines, hydraulics, and electrical systems is crucial.

What are the primary responsibilities of a Construction Equipment Mechanic?

The primary responsibilities of a Construction Equipment Mechanic involve diagnosing, repairing, and maintaining construction equipment, including excavators, bulldozers, backhoes, skid steers, and crawler cranes. They also perform preventative maintenance, conduct safety inspections, and fabricate custom parts.

What are the career prospects for a Construction Equipment Mechanic?

Construction Equipment Mechanics are in high demand due to the increasing reliance on heavy equipment in the construction industry. With experience and expertise, they can advance to supervisory roles, such as Fleet Manager or Service Manager, or specialize in specific areas, such as hydraulics or engine repair.

What are the educational qualifications required to become a Construction Equipment Mechanic?

Most Construction Equipment Mechanics have an Associate Degree in Diesel Technology or a related field. They may also have completed an apprenticeship program or received on-the-job training.

What are the key qualities of a successful Construction Equipment Mechanic?

Successful Construction Equipment Mechanics possess strong technical skills, problem-solving abilities, attention to detail, and a commitment to safety. They are also physically fit and able to work in various weather conditions.

What are the common challenges faced by a Construction Equipment Mechanic?

Common challenges faced by Construction Equipment Mechanics include diagnosing complex equipment issues, working in confined spaces, and dealing with heavy and potentially hazardous machinery. They must also keep up with advancements in technology and industry regulations.

What are the safety precautions that a Construction Equipment Mechanic should observe?

Construction Equipment Mechanics must adhere to strict safety protocols, including wearing appropriate protective gear, following lockout/tagout procedures, and maintaining a clean and organized work area. They should also be aware of the potential hazards associated with working with heavy machinery and take appropriate precautions.