Are you a seasoned Continuous Improvement Specialist seeking a new career path? Discover our professionally built Continuous Improvement Specialist Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

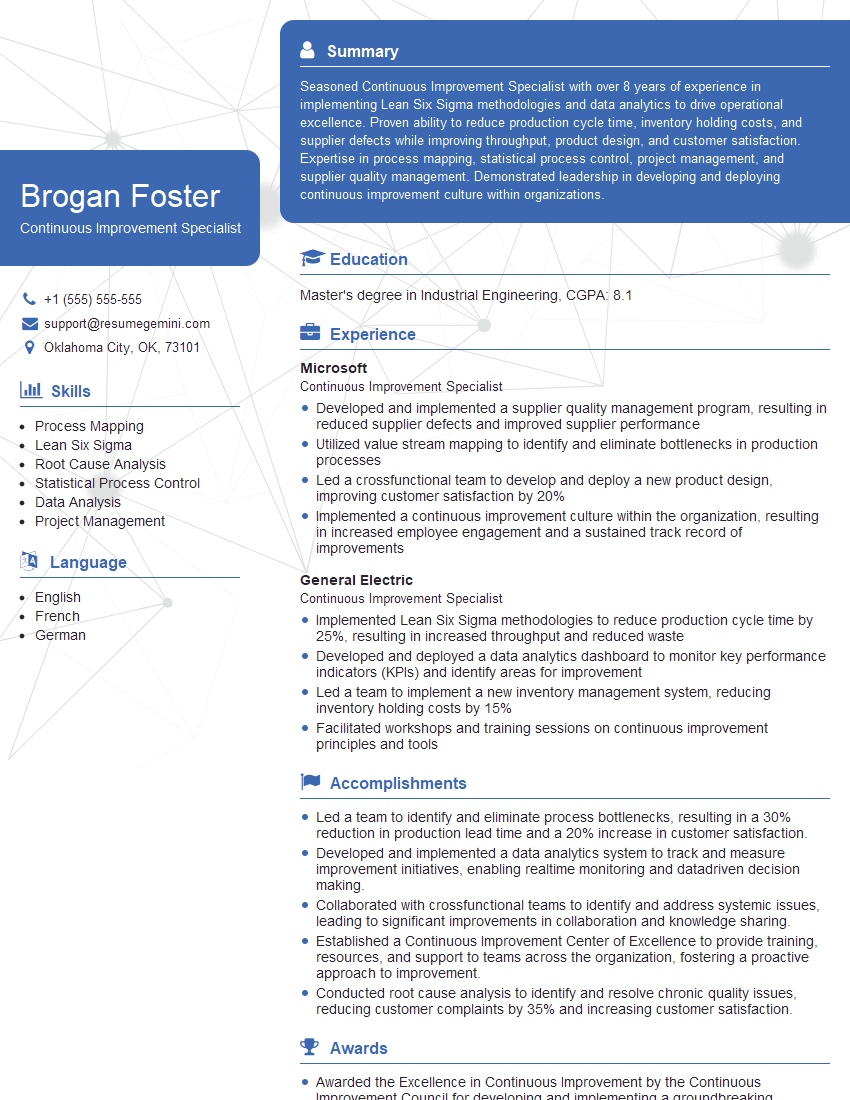

Brogan Foster

Continuous Improvement Specialist

Summary

Seasoned Continuous Improvement Specialist with over 8 years of experience in implementing Lean Six Sigma methodologies and data analytics to drive operational excellence. Proven ability to reduce production cycle time, inventory holding costs, and supplier defects while improving throughput, product design, and customer satisfaction. Expertise in process mapping, statistical process control, project management, and supplier quality management. Demonstrated leadership in developing and deploying continuous improvement culture within organizations.

Education

Master’s degree in Industrial Engineering

September 2017

Skills

- Process Mapping

- Lean Six Sigma

- Root Cause Analysis

- Statistical Process Control

- Data Analysis

- Project Management

Work Experience

Continuous Improvement Specialist

- Developed and implemented a supplier quality management program, resulting in reduced supplier defects and improved supplier performance

- Utilized value stream mapping to identify and eliminate bottlenecks in production processes

- Led a crossfunctional team to develop and deploy a new product design, improving customer satisfaction by 20%

- Implemented a continuous improvement culture within the organization, resulting in increased employee engagement and a sustained track record of improvements

Continuous Improvement Specialist

- Implemented Lean Six Sigma methodologies to reduce production cycle time by 25%, resulting in increased throughput and reduced waste

- Developed and deployed a data analytics dashboard to monitor key performance indicators (KPIs) and identify areas for improvement

- Led a team to implement a new inventory management system, reducing inventory holding costs by 15%

- Facilitated workshops and training sessions on continuous improvement principles and tools

Accomplishments

- Led a team to identify and eliminate process bottlenecks, resulting in a 30% reduction in production lead time and a 20% increase in customer satisfaction.

- Developed and implemented a data analytics system to track and measure improvement initiatives, enabling realtime monitoring and datadriven decision making.

- Collaborated with crossfunctional teams to identify and address systemic issues, leading to significant improvements in collaboration and knowledge sharing.

- Established a Continuous Improvement Center of Excellence to provide training, resources, and support to teams across the organization, fostering a proactive approach to improvement.

- Conducted root cause analysis to identify and resolve chronic quality issues, reducing customer complaints by 35% and increasing customer satisfaction.

Awards

- Awarded the Excellence in Continuous Improvement by the Continuous Improvement Council for developing and implementing a groundbreaking improvement program that resulted in a 25% increase in efficiency.

- Recognized with the Innovation in Continuous Improvement Award for pioneering a lean manufacturing initiative that reduced waste by 40% and improved product quality by 15%.

- Awarded the Continuous Improvement Leadership Award for mentoring and training junior engineers in Lean Six Sigma methodologies, fostering a culture of continuous improvement within the organization.

- Recognized with the Process Excellence Award for implementing a new workflow management system that automated tasks, streamlined processes, and reduced cycle time by 45%.

Certificates

- ASQ Certified Six Sigma Green Belt

- ASQ Certified Six Sigma Black Belt

- Lean Six Sigma Master Black Belt

- Certified Quality Engineer (CQE)

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Continuous Improvement Specialist

- Quantify your accomplishments using specific metrics to demonstrate the impact of your work.

- Highlight your ability to work effectively with cross-functional teams and stakeholders.

- Showcase your skills in data analysis and process mapping, which are essential for continuous improvement.

- Demonstrate your passion for driving operational excellence and improving organizational performance.

- Consider obtaining certifications in Lean Six Sigma or other continuous improvement methodologies to enhance your credibility.

Essential Experience Highlights for a Strong Continuous Improvement Specialist Resume

- Implemented Lean Six Sigma methodologies to streamline processes and reduce cycle times, resulting in increased efficiency and productivity.

- Developed and deployed data analytics dashboards to monitor key performance indicators (KPIs) and identify areas for improvement.

- Led cross-functional teams in implementing new inventory management systems, reducing inventory holding costs and improving inventory accuracy.

- Facilitated workshops and training sessions on continuous improvement principles and tools, empowering employees to drive ongoing improvements.

- Developed and implemented a supplier quality management program, resulting in reduced supplier defects and improved supplier performance.

- Utilized value stream mapping to identify and eliminate bottlenecks in production processes, improving overall flow and reducing waste.

- Led a cross-functional team to develop and deploy a new product design, improving customer satisfaction and increasing sales.

Frequently Asked Questions (FAQ’s) For Continuous Improvement Specialist

What is the role of a Continuous Improvement Specialist?

A Continuous Improvement Specialist is responsible for identifying, analyzing, and implementing improvements to processes, products, and services within an organization. They leverage methodologies such as Lean Six Sigma, data analytics, and process mapping to drive operational excellence, reduce waste, and enhance customer satisfaction.

What skills are essential for a Continuous Improvement Specialist?

Essential skills for a Continuous Improvement Specialist include process mapping, Lean Six Sigma, root cause analysis, statistical process control, data analysis, and project management. They should also possess strong communication, interpersonal, and problem-solving abilities.

What industries can Continuous Improvement Specialists work in?

Continuous Improvement Specialists are in demand across various industries, including manufacturing, healthcare, technology, retail, and finance. They play a vital role in optimizing processes, reducing costs, and improving efficiency in diverse organizational settings.

What is the career growth path for Continuous Improvement Specialists?

Continuous Improvement Specialists can advance to roles such as Senior Continuous Improvement Specialist, Continuous Improvement Manager, or Operational Excellence Leader. With experience and additional certifications, they can transition into leadership positions within quality management, operations, or engineering.

How can I become a Continuous Improvement Specialist?

To become a Continuous Improvement Specialist, you typically need a bachelor’s or master’s degree in industrial engineering, operations management, or a related field. Certifications in Lean Six Sigma, such as Green Belt or Black Belt, are highly desirable. Hands-on experience in process improvement initiatives and a passion for continuous learning are also valuable.

What is the job outlook for Continuous Improvement Specialists?

The job outlook for Continuous Improvement Specialists is projected to grow faster than average due to the increasing demand for operational efficiency and quality improvement in various industries. Organizations are seeking professionals who can drive innovation, reduce waste, and enhance customer satisfaction.