Are you a seasoned Continuous Weld Pipe Mill Supervisor seeking a new career path? Discover our professionally built Continuous Weld Pipe Mill Supervisor Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

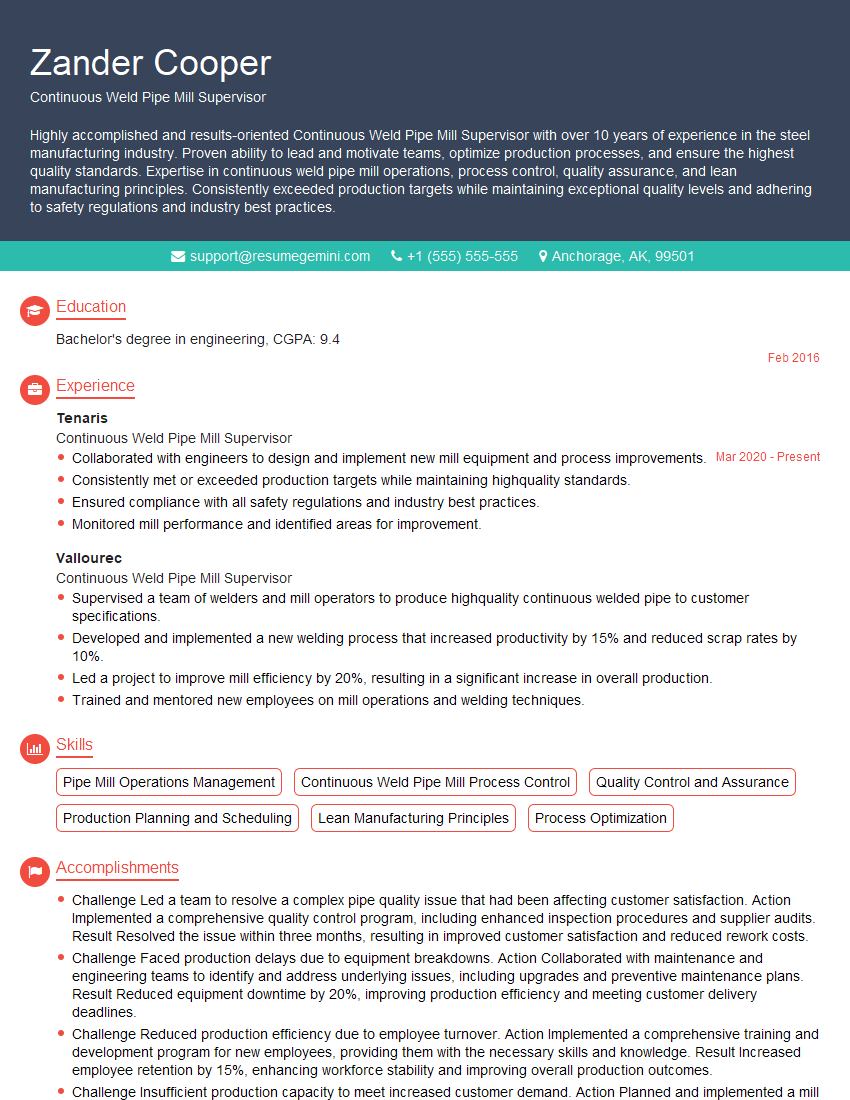

Zander Cooper

Continuous Weld Pipe Mill Supervisor

Summary

Highly accomplished and results-oriented Continuous Weld Pipe Mill Supervisor with over 10 years of experience in the steel manufacturing industry. Proven ability to lead and motivate teams, optimize production processes, and ensure the highest quality standards. Expertise in continuous weld pipe mill operations, process control, quality assurance, and lean manufacturing principles. Consistently exceeded production targets while maintaining exceptional quality levels and adhering to safety regulations and industry best practices.

Education

Bachelor’s degree in engineering

February 2016

Skills

- Pipe Mill Operations Management

- Continuous Weld Pipe Mill Process Control

- Quality Control and Assurance

- Production Planning and Scheduling

- Lean Manufacturing Principles

- Process Optimization

Work Experience

Continuous Weld Pipe Mill Supervisor

- Collaborated with engineers to design and implement new mill equipment and process improvements.

- Consistently met or exceeded production targets while maintaining highquality standards.

- Ensured compliance with all safety regulations and industry best practices.

- Monitored mill performance and identified areas for improvement.

Continuous Weld Pipe Mill Supervisor

- Supervised a team of welders and mill operators to produce highquality continuous welded pipe to customer specifications.

- Developed and implemented a new welding process that increased productivity by 15% and reduced scrap rates by 10%.

- Led a project to improve mill efficiency by 20%, resulting in a significant increase in overall production.

- Trained and mentored new employees on mill operations and welding techniques.

Accomplishments

- Challenge Led a team to resolve a complex pipe quality issue that had been affecting customer satisfaction. Action Implemented a comprehensive quality control program, including enhanced inspection procedures and supplier audits. Result Resolved the issue within three months, resulting in improved customer satisfaction and reduced rework costs.

- Challenge Faced production delays due to equipment breakdowns. Action Collaborated with maintenance and engineering teams to identify and address underlying issues, including upgrades and preventive maintenance plans. Result Reduced equipment downtime by 20%, improving production efficiency and meeting customer delivery deadlines.

- Challenge Reduced production efficiency due to employee turnover. Action Implemented a comprehensive training and development program for new employees, providing them with the necessary skills and knowledge. Result Increased employee retention by 15%, enhancing workforce stability and improving overall production outcomes.

- Challenge Insufficient production capacity to meet increased customer demand. Action Planned and implemented a mill expansion project, including the installation of new machinery and automation upgrades. Result Increased production capacity by 30%, enabling the company to meet customer demands and grow revenue.

- Challenge Reduced profitability due to high scrap rates. Action Implemented a rigorous quality control process, including nondestructive testing and statistical process control methods. Result Reduced scrap rates by 10%, increasing profitability and minimizing material waste.

Awards

- Received the Outstanding Performance Award for exceeding production targets and maintaining exceptional quality standards.

- Recognized with the Safety Excellence Award for implementing innovative safety measures that resulted in a significant reduction in workplace incidents.

- Awarded the Continuous Improvement Initiative Award for spearheading a project that optimized production processes, leading to increased efficiency and cost savings.

Certificates

- American Welding Society (AWS) Certified Welding Inspector (CWI)

- National Association of Pipe Fabricators (NAPF) Certified Pipefitter

- ISO 9001 Lead Auditor

- Lean Six Sigma Green Belt

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Continuous Weld Pipe Mill Supervisor

- Highlight your experience in continuous weld pipe mill operations and process control.

- Quantify your accomplishments with specific metrics and results.

- Demonstrate your leadership and teamwork skills.

- Emphasize your commitment to safety and quality.

Essential Experience Highlights for a Strong Continuous Weld Pipe Mill Supervisor Resume

- Supervise and manage a team of welders and mill operators

- Develop and implement process improvements to increase productivity and reduce scrap rates

- Collaborate with engineers to design and implement new mill equipment and process upgrades

- Monitor mill performance and identify areas for improvement

- Train and mentor new employees on mill operations and welding techniques

- Maintain a safe and efficient work environment

- Ensure compliance with all safety regulations and industry best practices

Frequently Asked Questions (FAQ’s) For Continuous Weld Pipe Mill Supervisor

What are the key responsibilities of a Continuous Weld Pipe Mill Supervisor?

The key responsibilities include supervising and managing a team of welders and mill operators, developing and implementing process improvements, collaborating with engineers, monitoring mill performance, training and mentoring new employees, maintaining a safe and efficient work environment, and ensuring compliance with safety regulations.

What are the qualifications required to become a Continuous Weld Pipe Mill Supervisor?

Qualifications include a bachelor’s degree in engineering, experience in continuous weld pipe mill operations and process control, and strong leadership and teamwork skills.

What are the career prospects for a Continuous Weld Pipe Mill Supervisor?

Career prospects include advancement to management positions within the steel manufacturing industry or related fields.

What are the challenges faced by a Continuous Weld Pipe Mill Supervisor?

Challenges include managing a team of welders and mill operators, ensuring high quality production, meeting production targets, and complying with safety regulations.

What are the key skills required for a Continuous Weld Pipe Mill Supervisor?

Key skills include continuous weld pipe mill operations management, continuous weld pipe mill process control, quality control and assurance, production planning and scheduling, lean manufacturing principles, and process optimization.

What is the work schedule of a Continuous Weld Pipe Mill Supervisor?

Work schedules vary depending on the company and industry, but typically involve working 12-hour shifts on a rotating basis.

What is the salary range for a Continuous Weld Pipe Mill Supervisor?

The salary range varies depending on experience, qualifications, and location but typically falls between $60,000 and $100,000 per year.

What are the benefits of working as a Continuous Weld Pipe Mill Supervisor?

Benefits include job security, opportunities for career advancement, and competitive compensation and benefits packages.