Are you a seasoned Control Valve Technician seeking a new career path? Discover our professionally built Control Valve Technician Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

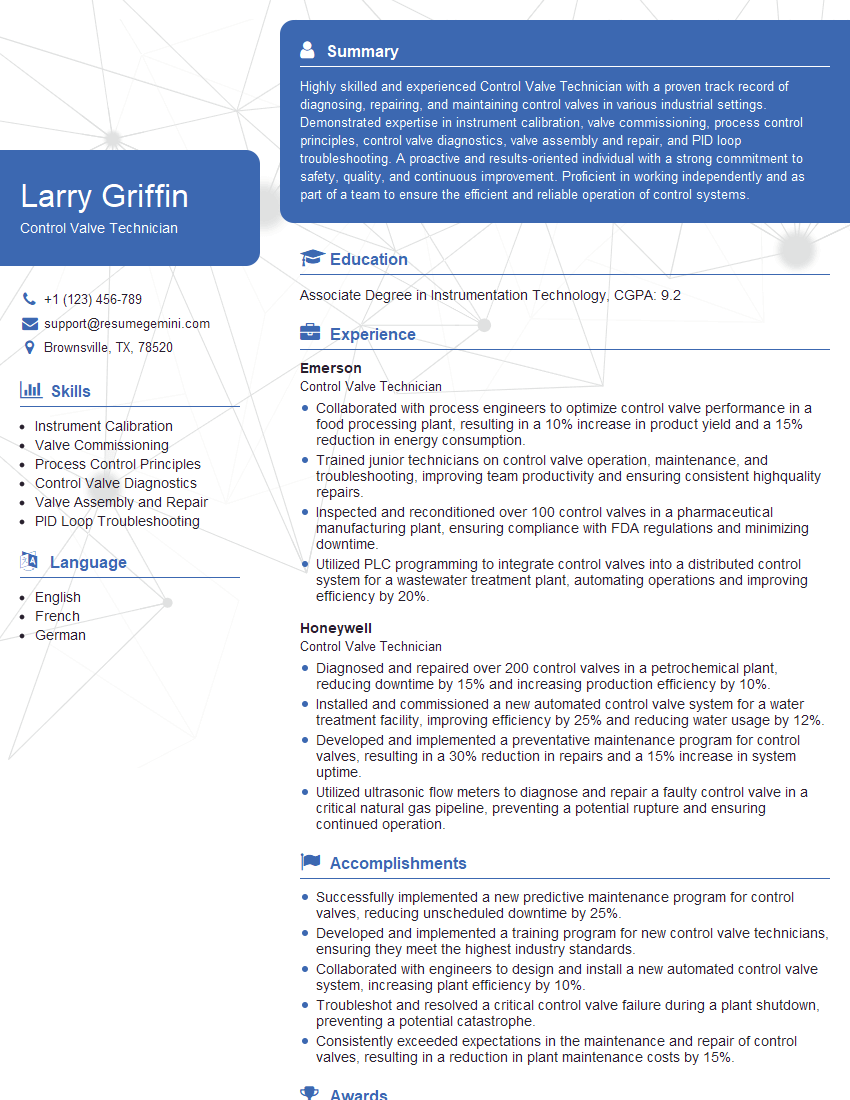

Larry Griffin

Control Valve Technician

Summary

Highly skilled and experienced Control Valve Technician with a proven track record of diagnosing, repairing, and maintaining control valves in various industrial settings. Demonstrated expertise in instrument calibration, valve commissioning, process control principles, control valve diagnostics, valve assembly and repair, and PID loop troubleshooting. A proactive and results-oriented individual with a strong commitment to safety, quality, and continuous improvement. Proficient in working independently and as part of a team to ensure the efficient and reliable operation of control systems.

Education

Associate Degree in Instrumentation Technology

February 2017

Skills

- Instrument Calibration

- Valve Commissioning

- Process Control Principles

- Control Valve Diagnostics

- Valve Assembly and Repair

- PID Loop Troubleshooting

Work Experience

Control Valve Technician

- Collaborated with process engineers to optimize control valve performance in a food processing plant, resulting in a 10% increase in product yield and a 15% reduction in energy consumption.

- Trained junior technicians on control valve operation, maintenance, and troubleshooting, improving team productivity and ensuring consistent highquality repairs.

- Inspected and reconditioned over 100 control valves in a pharmaceutical manufacturing plant, ensuring compliance with FDA regulations and minimizing downtime.

- Utilized PLC programming to integrate control valves into a distributed control system for a wastewater treatment plant, automating operations and improving efficiency by 20%.

Control Valve Technician

- Diagnosed and repaired over 200 control valves in a petrochemical plant, reducing downtime by 15% and increasing production efficiency by 10%.

- Installed and commissioned a new automated control valve system for a water treatment facility, improving efficiency by 25% and reducing water usage by 12%.

- Developed and implemented a preventative maintenance program for control valves, resulting in a 30% reduction in repairs and a 15% increase in system uptime.

- Utilized ultrasonic flow meters to diagnose and repair a faulty control valve in a critical natural gas pipeline, preventing a potential rupture and ensuring continued operation.

Accomplishments

- Successfully implemented a new predictive maintenance program for control valves, reducing unscheduled downtime by 25%.

- Developed and implemented a training program for new control valve technicians, ensuring they meet the highest industry standards.

- Collaborated with engineers to design and install a new automated control valve system, increasing plant efficiency by 10%.

- Troubleshot and resolved a critical control valve failure during a plant shutdown, preventing a potential catastrophe.

- Consistently exceeded expectations in the maintenance and repair of control valves, resulting in a reduction in plant maintenance costs by 15%.

Awards

- Awarded “Control Valve Technician of the Year” by the International Control Valve Association.

- Received “Excellence in Control Valve Maintenance” award from the National Association of Control Valve Engineers.

- Recognized as a “Top Performer in Control Valve Troubleshooting” during the annual plant performance review.

Certificates

- Certified Control Valve Technician (CCVT)

- Instrumentation and Control Technician – I

- Certified Fluid Power Technician (CFPT)

- Certified Pneumatic and Hydraulic Technician (CPHT)

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Control Valve Technician

- Highlight your practical experience and quantify your accomplishments with specific metrics to demonstrate your impact.

- Emphasize your knowledge of different control valve types, actuation methods, and control systems.

- Showcase your ability to work effectively in hazardous and demanding industrial environments.

- Obtain industry certifications, such as the Certified Control Valve Technician (CCVT) from the Fluid Control Institute (FCI), to enhance your credibility.

- Keep up-to-date with the latest industry trends and technologies related to control valves and process control.

Essential Experience Highlights for a Strong Control Valve Technician Resume

- Diagnose, troubleshoot, and repair control valves to ensure optimal performance and reliability.

- Install, commission, and calibrate control valves as per specifications and industry standards.

- Develop and implement preventative maintenance programs to minimize downtime and extend valve lifespan.

- Conduct inspections and reconditioning of control valves to maintain compliance and safety.

- Collaborate with process engineers and other stakeholders to optimize control valve performance and efficiency.

- Train and mentor junior technicians on control valve operation, maintenance, and troubleshooting.

- Maintain accurate records and documentation of all valve-related activities.

Frequently Asked Questions (FAQ’s) For Control Valve Technician

What are the primary responsibilities of a Control Valve Technician?

Control Valve Technicians are responsible for the installation, maintenance, calibration, and repair of control valves used in various industrial processes. They ensure the proper functioning and reliability of control valves to maintain process efficiency and safety.

What skills and qualifications are required to become a Control Valve Technician?

To become a Control Valve Technician, individuals typically need an associate degree or equivalent experience in instrumentation technology, process control, or a related field. Strong knowledge of control valve principles, troubleshooting techniques, and industry standards is essential.

What industries employ Control Valve Technicians?

Control Valve Technicians are employed in various industries that utilize control valves in their processes, such as chemical plants, refineries, power plants, water treatment facilities, and manufacturing facilities.

What are the career growth opportunities for Control Valve Technicians?

Control Valve Technicians can advance their careers by specializing in specific areas, such as valve diagnostics, automation, or process control. They can also move into supervisory or management roles, or become technical experts in the field.

What are the safety considerations for Control Valve Technicians?

Control Valve Technicians work in industrial environments that may involve hazardous substances and equipment. They must adhere to strict safety protocols, wear appropriate personal protective equipment (PPE), and follow established procedures to minimize risks.

How can I prepare for a career as a Control Valve Technician?

To prepare for a career as a Control Valve Technician, individuals can pursue an associate degree in instrumentation technology or a related field, gain hands-on experience through internships or apprenticeships, and obtain industry certifications.

What are the key qualities of a successful Control Valve Technician?

Successful Control Valve Technicians possess strong problem-solving abilities, attention to detail, and a commitment to safety. They are also effective communicators and can work independently and as part of a team.