Are you a seasoned Controls Designer seeking a new career path? Discover our professionally built Controls Designer Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

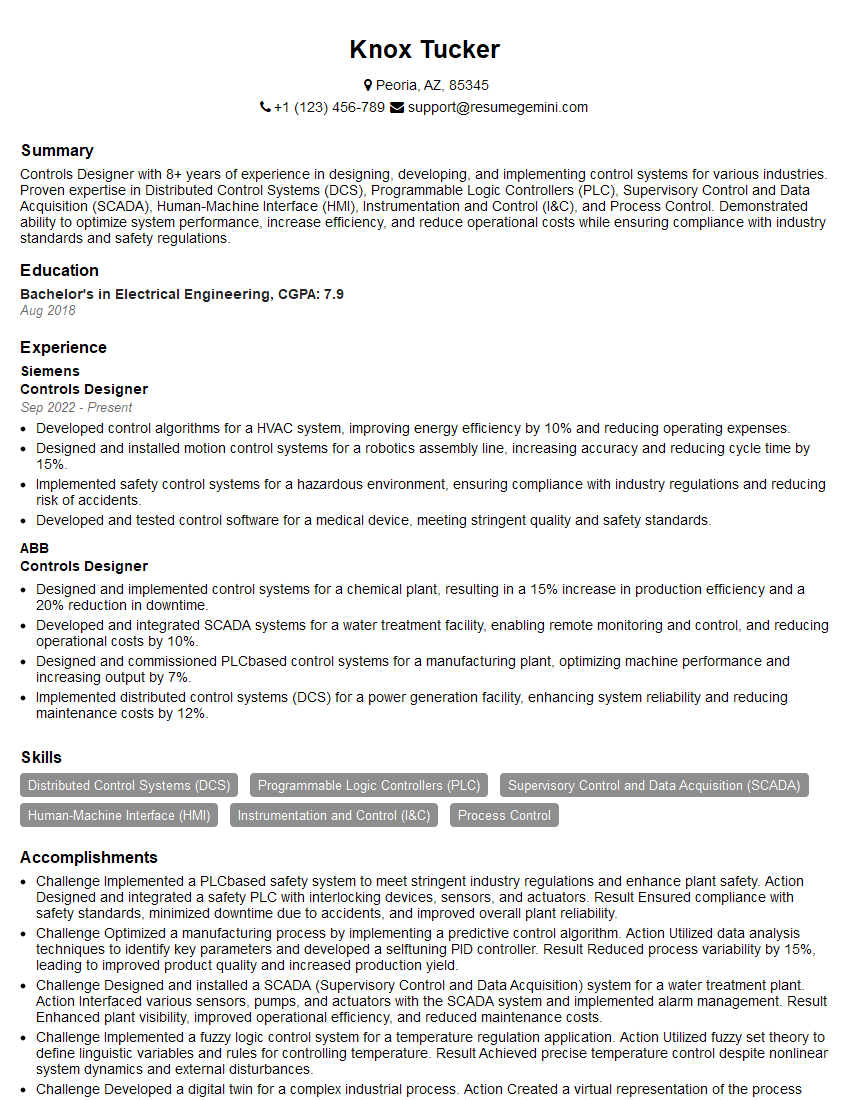

Knox Tucker

Controls Designer

Summary

Controls Designer with 8+ years of experience in designing, developing, and implementing control systems for various industries. Proven expertise in Distributed Control Systems (DCS), Programmable Logic Controllers (PLC), Supervisory Control and Data Acquisition (SCADA), Human-Machine Interface (HMI), Instrumentation and Control (I&C), and Process Control. Demonstrated ability to optimize system performance, increase efficiency, and reduce operational costs while ensuring compliance with industry standards and safety regulations.

Education

Bachelor’s in Electrical Engineering

August 2018

Skills

- Distributed Control Systems (DCS)

- Programmable Logic Controllers (PLC)

- Supervisory Control and Data Acquisition (SCADA)

- Human-Machine Interface (HMI)

- Instrumentation and Control (I&C)

- Process Control

Work Experience

Controls Designer

- Developed control algorithms for a HVAC system, improving energy efficiency by 10% and reducing operating expenses.

- Designed and installed motion control systems for a robotics assembly line, increasing accuracy and reducing cycle time by 15%.

- Implemented safety control systems for a hazardous environment, ensuring compliance with industry regulations and reducing risk of accidents.

- Developed and tested control software for a medical device, meeting stringent quality and safety standards.

Controls Designer

- Designed and implemented control systems for a chemical plant, resulting in a 15% increase in production efficiency and a 20% reduction in downtime.

- Developed and integrated SCADA systems for a water treatment facility, enabling remote monitoring and control, and reducing operational costs by 10%.

- Designed and commissioned PLCbased control systems for a manufacturing plant, optimizing machine performance and increasing output by 7%.

- Implemented distributed control systems (DCS) for a power generation facility, enhancing system reliability and reducing maintenance costs by 12%.

Accomplishments

- Challenge Implemented a PLCbased safety system to meet stringent industry regulations and enhance plant safety. Action Designed and integrated a safety PLC with interlocking devices, sensors, and actuators. Result Ensured compliance with safety standards, minimized downtime due to accidents, and improved overall plant reliability.

- Challenge Optimized a manufacturing process by implementing a predictive control algorithm. Action Utilized data analysis techniques to identify key parameters and developed a selftuning PID controller. Result Reduced process variability by 15%, leading to improved product quality and increased production yield.

- Challenge Designed and installed a SCADA (Supervisory Control and Data Acquisition) system for a water treatment plant. Action Interfaced various sensors, pumps, and actuators with the SCADA system and implemented alarm management. Result Enhanced plant visibility, improved operational efficiency, and reduced maintenance costs.

- Challenge Implemented a fuzzy logic control system for a temperature regulation application. Action Utilized fuzzy set theory to define linguistic variables and rules for controlling temperature. Result Achieved precise temperature control despite nonlinear system dynamics and external disturbances.

- Challenge Developed a digital twin for a complex industrial process. Action Created a virtual representation of the process using sensor data and physicsbased models. Result Enabled predictive analytics, remote monitoring, and optimized process control.

Awards

- Recipient of the ISA (International Society of Automation) Excellence in Controls Design Award for developing an innovative control system that significantly improved process efficiency by 25%.

- Winner of the IEEE (Institute of Electrical and Electronics Engineers) Young Professional Award for outstanding contributions to the field of controls engineering, specifically in the application of advanced controls.

- Recognition from the Control Systems Society (CSS) for significant contributions to the development and implementation of distributed control systems in the automotive industry.

- Honored with the ASME (American Society of Mechanical Engineers) Controls Engineering Innovation Award for developing a unique control strategy for a robotic surgical system.

Certificates

- Certified Automation Professional (CAP)

- Certified Control Systems Technician (CCST)

- ISA Certified Control Systems Engineer (ICSE)

- Siemens Certified Controls Professional (SCCP)

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Controls Designer

- Highlight your technical skills and experience in the resume summary, emphasizing the specific control systems and technologies you have worked with.

- Quantify your accomplishments whenever possible, using metrics to demonstrate the impact of your work on efficiency, productivity, and cost savings.

- Showcase your problem-solving abilities and provide examples of how you have overcome challenges and implemented innovative solutions in your previous roles.

- Obtain industry certifications, such as the Certified Automation Professional (CAP) or the Professional Engineer (PE) license, to enhance your credibility and demonstrate your commitment to professional development.

Essential Experience Highlights for a Strong Controls Designer Resume

- Design and implement control systems for industrial processes, power plants, and manufacturing facilities

- Develop and integrate SCADA systems for remote monitoring, data acquisition, and control

- Design and commission PLC-based control systems to automate machine operations and optimize performance

- Implement DCS for power generation, distribution, and transmission systems to enhance reliability and efficiency

- Develop control algorithms and optimization strategies to improve energy efficiency, reduce operating expenses, and minimize downtime

- Design and install motion control systems for robotics and automated assembly lines to enhance accuracy and productivity

- Implement safety control systems to ensure compliance with industry regulations, mitigate risks, and prevent accidents

Frequently Asked Questions (FAQ’s) For Controls Designer

What is the primary role of a Controls Designer?

A Controls Designer is responsible for designing, implementing, and maintaining control systems for various industries, including manufacturing, power generation, and process control. They work closely with engineers, technicians, and operators to ensure that the control systems meet the specific requirements and objectives of the application.

What are the key skills required for a Controls Designer?

A Controls Designer typically requires a strong understanding of control theory, electrical engineering principles, and programming languages. They should also be proficient in using computer-aided design (CAD) software and have a thorough understanding of industry standards and regulations.

What are the different types of control systems that Controls Designers work with?

Controls Designers work with a wide range of control systems, including programmable logic controllers (PLCs), distributed control systems (DCSs), supervisory control and data acquisition (SCADA) systems, and motion control systems. They may also specialize in specific industries, such as manufacturing, power generation, or process control.

What are the career prospects for Controls Designers?

Controls Designers are in high demand due to the increasing automation of industrial processes and the growing need for efficient and reliable control systems. They can work in various industries and have the opportunity to advance to management or consulting roles.

How can I become a Controls Designer?

To become a Controls Designer, you typically need a bachelor’s degree in electrical engineering or a related field. You can also gain experience through internships or entry-level positions in the field. Additionally, obtaining industry certifications can enhance your credibility and career prospects.

What is the average salary for a Controls Designer?

The average salary for a Controls Designer varies depending on their experience, location, and industry. According to the U.S. Bureau of Labor Statistics, the median annual salary for Electrical and Electronics Engineers, which includes Controls Designers, was $109,830 in May 2021.

What are some of the challenges that Controls Designers face?

Controls Designers often face challenges related to system complexity, integration of different technologies, and meeting industry standards and regulations. They may also need to work under tight deadlines and in demanding environments.