Are you a seasoned Conventional Machinist seeking a new career path? Discover our professionally built Conventional Machinist Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

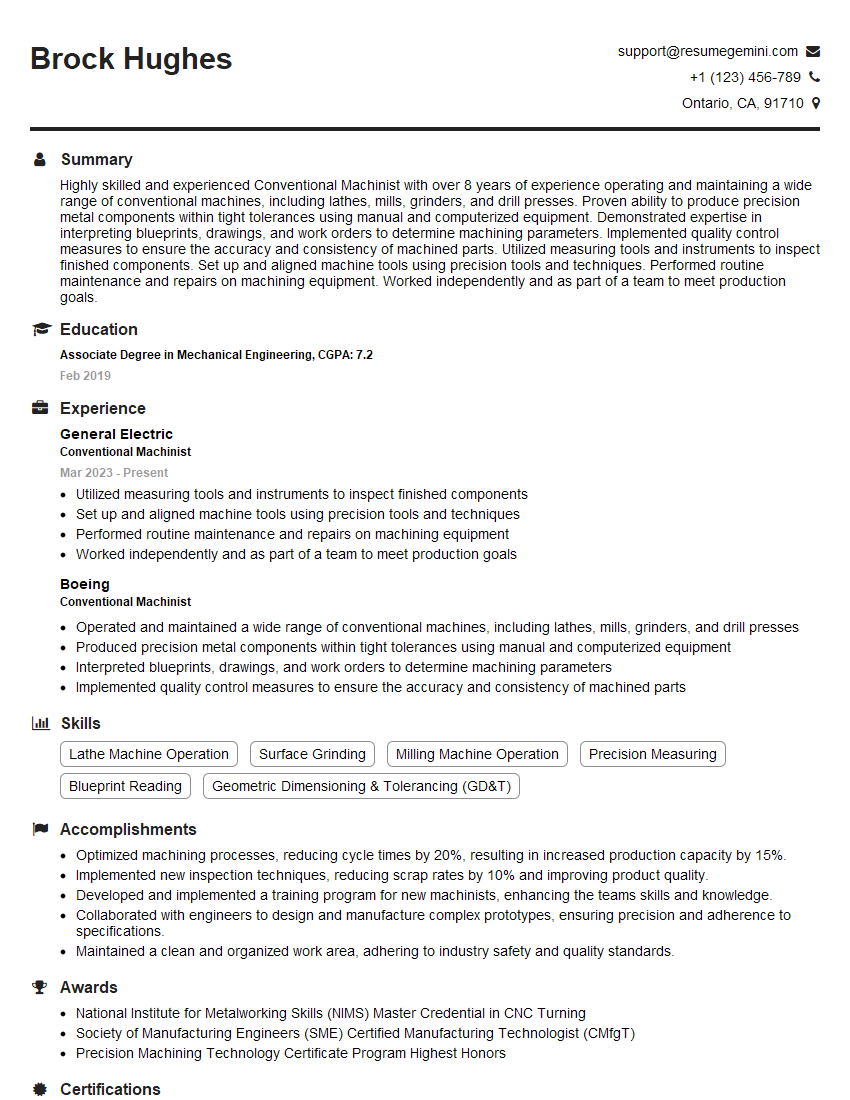

Brock Hughes

Conventional Machinist

Summary

Highly skilled and experienced Conventional Machinist with over 8 years of experience operating and maintaining a wide range of conventional machines, including lathes, mills, grinders, and drill presses. Proven ability to produce precision metal components within tight tolerances using manual and computerized equipment. Demonstrated expertise in interpreting blueprints, drawings, and work orders to determine machining parameters. Implemented quality control measures to ensure the accuracy and consistency of machined parts. Utilized measuring tools and instruments to inspect finished components. Set up and aligned machine tools using precision tools and techniques. Performed routine maintenance and repairs on machining equipment. Worked independently and as part of a team to meet production goals.

Education

Associate Degree in Mechanical Engineering

February 2019

Skills

- Lathe Machine Operation

- Surface Grinding

- Milling Machine Operation

- Precision Measuring

- Blueprint Reading

- Geometric Dimensioning & Tolerancing (GD&T)

Work Experience

Conventional Machinist

- Utilized measuring tools and instruments to inspect finished components

- Set up and aligned machine tools using precision tools and techniques

- Performed routine maintenance and repairs on machining equipment

- Worked independently and as part of a team to meet production goals

Conventional Machinist

- Operated and maintained a wide range of conventional machines, including lathes, mills, grinders, and drill presses

- Produced precision metal components within tight tolerances using manual and computerized equipment

- Interpreted blueprints, drawings, and work orders to determine machining parameters

- Implemented quality control measures to ensure the accuracy and consistency of machined parts

Accomplishments

- Optimized machining processes, reducing cycle times by 20%, resulting in increased production capacity by 15%.

- Implemented new inspection techniques, reducing scrap rates by 10% and improving product quality.

- Developed and implemented a training program for new machinists, enhancing the teams skills and knowledge.

- Collaborated with engineers to design and manufacture complex prototypes, ensuring precision and adherence to specifications.

- Maintained a clean and organized work area, adhering to industry safety and quality standards.

Awards

- National Institute for Metalworking Skills (NIMS) Master Credential in CNC Turning

- Society of Manufacturing Engineers (SME) Certified Manufacturing Technologist (CMfgT)

- Precision Machining Technology Certificate Program Highest Honors

Certificates

- National Institute for Metalworking Skills (NIMS) Credentials

- American Society of Mechanical Engineers (ASME) Certification

- International Organization for Standardization (ISO) Certification

- Certified Manufacturing Technologist (CMfgT)

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Conventional Machinist

- Highlight your experience and skills in operating and maintaining a wide range of conventional machines.

- Showcase your ability to produce precision metal components within tight tolerances.

- Demonstrate your expertise in interpreting blueprints, drawings, and work orders to determine machining parameters.

- Emphasize your experience in implementing quality control measures and utilizing measuring tools and instruments to inspect finished components.

Essential Experience Highlights for a Strong Conventional Machinist Resume

- Operated and maintained a wide range of conventional machines, including lathes, mills, grinders, and drill presses

- Produced precision metal components within tight tolerances using manual and computerized equipment

- Interpreted blueprints, drawings, and work orders to determine machining parameters

- Implemented quality control measures to ensure the accuracy and consistency of machined parts

- Utilized measuring tools and instruments to inspect finished components

- Set up and aligned machine tools using precision tools and techniques

- Performed routine maintenance and repairs on machining equipment

Frequently Asked Questions (FAQ’s) For Conventional Machinist

What are the primary responsibilities of a Conventional Machinist?

Conventional Machinists are responsible for operating and maintaining a wide range of conventional machines, including lathes, mills, grinders, and drill presses. They produce precision metal components within tight tolerances using manual and computerized equipment, and interpret blueprints, drawings, and work orders to determine machining parameters. They also implement quality control measures to ensure the accuracy and consistency of machined parts, utilize measuring tools and instruments to inspect finished components, and set up and align machine tools using precision tools and techniques.

What skills are required to be a successful Conventional Machinist?

Successful Conventional Machinists possess a combination of technical skills and experience, including proficiency in operating and maintaining conventional machines, the ability to interpret blueprints and drawings, and expertise in precision measurement and quality control. They should also have a strong understanding of machining processes and materials.

What are the career prospects for Conventional Machinists?

Conventional Machinists are in high demand due to the increasing need for precision-machined components in various industries, such as aerospace, automotive, and manufacturing. They can advance their careers by specializing in specific areas, such as CNC programming or tool and die making, or by moving into supervisory or management roles.

What is the average salary for a Conventional Machinist?

The average salary for a Conventional Machinist varies depending on experience, location, and industry. According to the U.S. Bureau of Labor Statistics, the median annual salary for Machinists and Tool and Die Makers was $49,250 in May 2021.

What are the educational requirements for becoming a Conventional Machinist?

While a high school diploma or equivalent is typically the minimum educational requirement for entry-level positions, many employers prefer candidates with an associate degree or certificate in machining or a related field.

Is it possible to become a Conventional Machinist through an apprenticeship?

Yes, many Conventional Machinists complete an apprenticeship program to gain the necessary skills and experience. Apprenticeship programs typically combine on-the-job training with classroom instruction, and can take several years to complete.

What are the safety precautions that Conventional Machinists should follow?

Conventional Machinists should always prioritize safety by wearing appropriate personal protective equipment, such as safety glasses, gloves, and earplugs. They should also be aware of the potential hazards associated with operating machinery, and follow established safety protocols to minimize the risk of accidents.