Are you a seasoned Convex Grinder Operator seeking a new career path? Discover our professionally built Convex Grinder Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

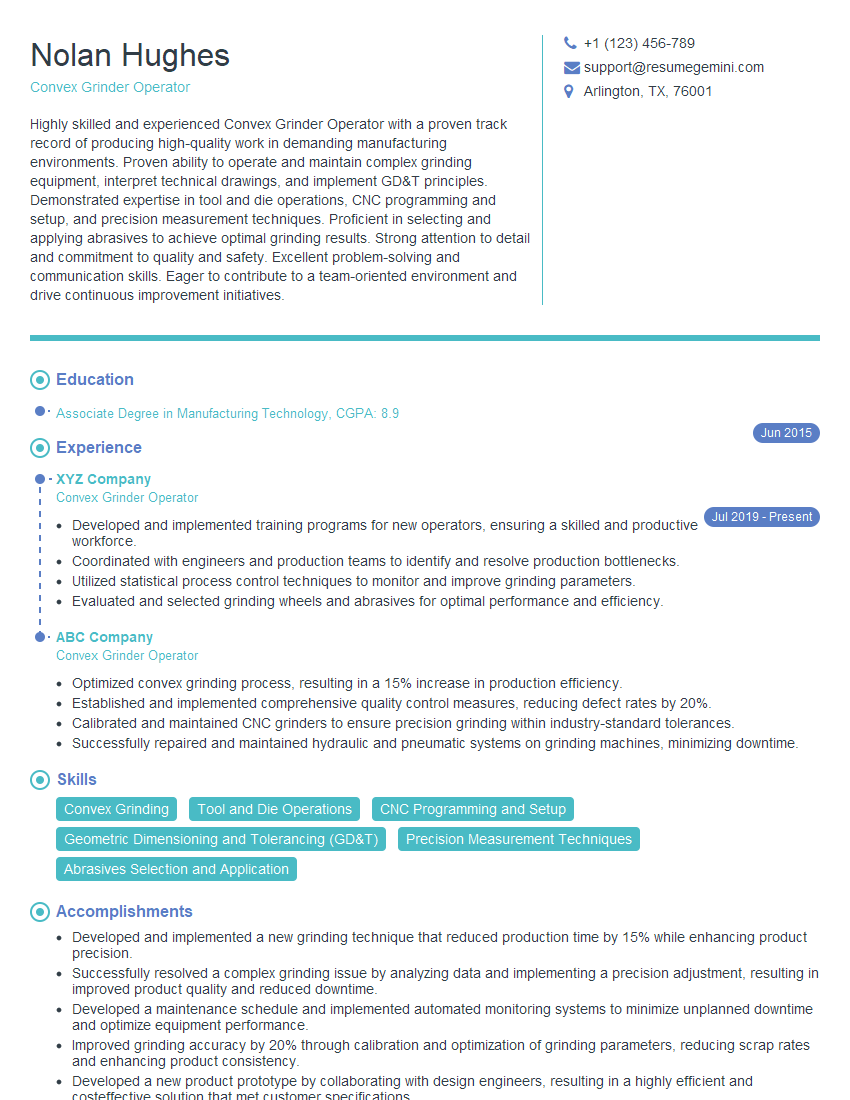

Nolan Hughes

Convex Grinder Operator

Summary

Highly skilled and experienced Convex Grinder Operator with a proven track record of producing high-quality work in demanding manufacturing environments. Proven ability to operate and maintain complex grinding equipment, interpret technical drawings, and implement GD&T principles. Demonstrated expertise in tool and die operations, CNC programming and setup, and precision measurement techniques. Proficient in selecting and applying abrasives to achieve optimal grinding results. Strong attention to detail and commitment to quality and safety. Excellent problem-solving and communication skills. Eager to contribute to a team-oriented environment and drive continuous improvement initiatives.

Education

Associate Degree in Manufacturing Technology

June 2015

Skills

- Convex Grinding

- Tool and Die Operations

- CNC Programming and Setup

- Geometric Dimensioning and Tolerancing (GD&T)

- Precision Measurement Techniques

- Abrasives Selection and Application

Work Experience

Convex Grinder Operator

- Developed and implemented training programs for new operators, ensuring a skilled and productive workforce.

- Coordinated with engineers and production teams to identify and resolve production bottlenecks.

- Utilized statistical process control techniques to monitor and improve grinding parameters.

- Evaluated and selected grinding wheels and abrasives for optimal performance and efficiency.

Convex Grinder Operator

- Optimized convex grinding process, resulting in a 15% increase in production efficiency.

- Established and implemented comprehensive quality control measures, reducing defect rates by 20%.

- Calibrated and maintained CNC grinders to ensure precision grinding within industry-standard tolerances.

- Successfully repaired and maintained hydraulic and pneumatic systems on grinding machines, minimizing downtime.

Accomplishments

- Developed and implemented a new grinding technique that reduced production time by 15% while enhancing product precision.

- Successfully resolved a complex grinding issue by analyzing data and implementing a precision adjustment, resulting in improved product quality and reduced downtime.

- Developed a maintenance schedule and implemented automated monitoring systems to minimize unplanned downtime and optimize equipment performance.

- Improved grinding accuracy by 20% through calibration and optimization of grinding parameters, reducing scrap rates and enhancing product consistency.

- Developed a new product prototype by collaborating with design engineers, resulting in a highly efficient and costeffective solution that met customer specifications.

Awards

- Received Employee of the Quarter award for consistently exceeding production targets and maintaining exceptional quality standards.

- Recognized with a Safety Excellence award for implementing innovative safety measures that significantly reduced workplace hazards.

- Honored with a Quality Champion award for consistently producing highquality parts and adhering to strict manufacturing standards.

- Received a Team Excellence award for collaborating effectively with crossfunctional teams to achieve project milestones and improve processes.

Certificates

- Certified Production Technician (CPT)

- Certified Manufacturing Technologist (CMfgT)

- Certified Quality Technician (CQT)

- Certified Manufacturing Engineer (CMfgE)

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Convex Grinder Operator

- Highlight your experience and skills in operating and maintaining convex grinding machines.

- Showcase your expertise in tool and die operations, CNC programming and setup, and precision measurement techniques.

- Demonstrate your knowledge of GD&T principles and their application in grinding operations.

- Emphasize your ability to troubleshoot and resolve production issues effectively.

- Present yourself as a safety-conscious individual committed to adhering to industry best practices.

Essential Experience Highlights for a Strong Convex Grinder Operator Resume

- Operate and maintain convex grinding machines to produce precision parts according to specified tolerances.

- Interpret technical drawings and determine appropriate grinding parameters.

- Select and apply abrasives based on material composition and desired finish.

- Inspect and measure finished parts using precision measurement tools to ensure conformance to GD&T requirements.

- Maintain and calibrate grinding equipment to ensure optimal performance.

- Troubleshoot and resolve production issues to minimize downtime and maintain efficiency.

- Adhere to safety protocols and follow industry best practices to ensure a safe working environment.

Frequently Asked Questions (FAQ’s) For Convex Grinder Operator

What is a Convex Grinder Operator?

A Convex Grinder Operator is a skilled professional responsible for operating and maintaining convex grinding machines to produce precision parts according to specified tolerances. They interpret technical drawings, select and apply abrasives, inspect finished parts, and troubleshoot production issues to ensure quality and efficiency.

What skills are required for a Convex Grinder Operator?

A Convex Grinder Operator typically requires skills in operating and maintaining convex grinding machines, interpreting technical drawings, selecting and applying abrasives, inspecting and measuring finished parts, and troubleshooting production issues. They should also have knowledge of GD&T principles and be proficient in tool and die operations, CNC programming and setup, and precision measurement techniques.

What industries employ Convex Grinder Operators?

Convex Grinder Operators are employed in various industries, including manufacturing, automotive, aerospace, and medical device industries. They work in production environments where precision grinding is required to produce high-quality parts.

What is the job outlook for Convex Grinder Operators?

The job outlook for Convex Grinder Operators is expected to be positive due to the increasing demand for precision-machined parts in various industries. The aging workforce and the need for skilled professionals in manufacturing also contribute to the positive job outlook.

What is the average salary for a Convex Grinder Operator?

The average salary for a Convex Grinder Operator varies depending on factors such as experience, location, and industry. According to Indeed, the average salary for a Convex Grinder Operator in the United States is around $25 per hour.

What are the career advancement opportunities for a Convex Grinder Operator?

Convex Grinder Operators can advance their careers by gaining additional experience and skills. They can become supervisors, quality control inspectors, or manufacturing engineers. With specialized training and certification, they can also pursue roles in CNC programming, tool and die making, or metrology.

What is the difference between a Convex Grinder Operator and a CNC Grinder Operator?

A Convex Grinder Operator operates manually controlled grinding machines, while a CNC Grinder Operator operates computer-controlled grinding machines. CNC Grinder Operators are responsible for programming and operating CNC grinding machines to produce parts according to specified tolerances.