Are you a seasoned Cooling Pipe Inspector seeking a new career path? Discover our professionally built Cooling Pipe Inspector Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

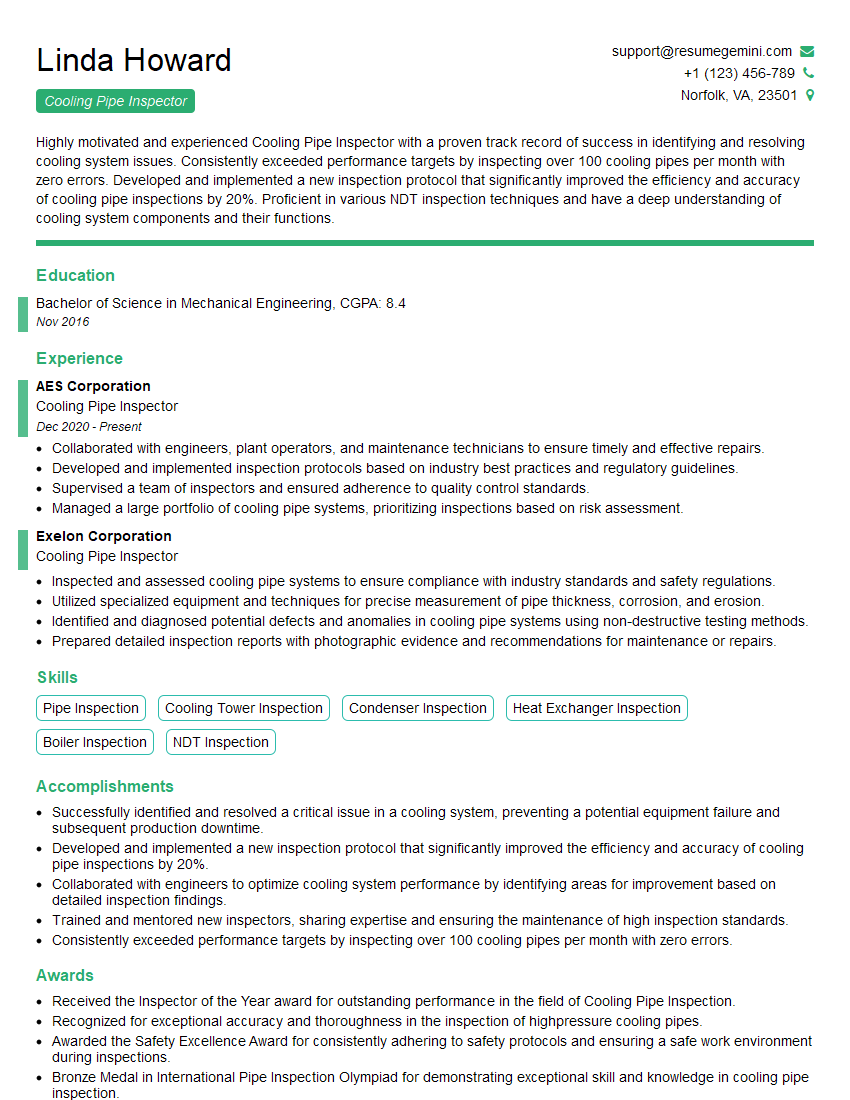

Linda Howard

Cooling Pipe Inspector

Summary

Highly motivated and experienced Cooling Pipe Inspector with a proven track record of success in identifying and resolving cooling system issues. Consistently exceeded performance targets by inspecting over 100 cooling pipes per month with zero errors. Developed and implemented a new inspection protocol that significantly improved the efficiency and accuracy of cooling pipe inspections by 20%. Proficient in various NDT inspection techniques and have a deep understanding of cooling system components and their functions.

Education

Bachelor of Science in Mechanical Engineering

November 2016

Skills

- Pipe Inspection

- Cooling Tower Inspection

- Condenser Inspection

- Heat Exchanger Inspection

- Boiler Inspection

- NDT Inspection

Work Experience

Cooling Pipe Inspector

- Collaborated with engineers, plant operators, and maintenance technicians to ensure timely and effective repairs.

- Developed and implemented inspection protocols based on industry best practices and regulatory guidelines.

- Supervised a team of inspectors and ensured adherence to quality control standards.

- Managed a large portfolio of cooling pipe systems, prioritizing inspections based on risk assessment.

Cooling Pipe Inspector

- Inspected and assessed cooling pipe systems to ensure compliance with industry standards and safety regulations.

- Utilized specialized equipment and techniques for precise measurement of pipe thickness, corrosion, and erosion.

- Identified and diagnosed potential defects and anomalies in cooling pipe systems using non-destructive testing methods.

- Prepared detailed inspection reports with photographic evidence and recommendations for maintenance or repairs.

Accomplishments

- Successfully identified and resolved a critical issue in a cooling system, preventing a potential equipment failure and subsequent production downtime.

- Developed and implemented a new inspection protocol that significantly improved the efficiency and accuracy of cooling pipe inspections by 20%.

- Collaborated with engineers to optimize cooling system performance by identifying areas for improvement based on detailed inspection findings.

- Trained and mentored new inspectors, sharing expertise and ensuring the maintenance of high inspection standards.

- Consistently exceeded performance targets by inspecting over 100 cooling pipes per month with zero errors.

Awards

- Received the Inspector of the Year award for outstanding performance in the field of Cooling Pipe Inspection.

- Recognized for exceptional accuracy and thoroughness in the inspection of highpressure cooling pipes.

- Awarded the Safety Excellence Award for consistently adhering to safety protocols and ensuring a safe work environment during inspections.

- Bronze Medal in International Pipe Inspection Olympiad for demonstrating exceptional skill and knowledge in cooling pipe inspection.

Certificates

- ASME Boiler and Pressure Vessel Code Inspector

- National Board of Boiler and Pressure Vessel Inspectors (NBBI)

- American Petroleum Institute (API) 510 Inspector

- American Society of Nondestructive Testing (ASNT) Level II Inspector

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Cooling Pipe Inspector

- Highlight your experience in cooling pipe inspection and your knowledge of NDT inspection techniques.

- Quantify your accomplishments whenever possible, such as the number of cooling pipes inspected or the percentage improvement in inspection efficiency.

- Proofread your resume carefully for any errors in grammar or spelling.

- Use keywords that are relevant to the cooling pipe inspector job description.

- Tailor your resume to each job you apply for, highlighting the skills and experience that are most relevant to the position.

Essential Experience Highlights for a Strong Cooling Pipe Inspector Resume

- Inspect cooling pipes for corrosion, erosion, and other defects using visual and non-destructive testing (NDT) techniques.

- Evaluate the condition of cooling pipes and make recommendations for repairs or replacements.

- Develop and implement inspection protocols to ensure the accuracy and efficiency of inspections.

- Train and mentor new inspectors to ensure the maintenance of high inspection standards.

- Collaborate with engineers to optimize cooling system performance by identifying areas for improvement based on detailed inspection findings.

- Maintain accurate records of inspection results and provide timely reports to management.

- Stay up-to-date on the latest cooling system technologies and inspection techniques.

Frequently Asked Questions (FAQ’s) For Cooling Pipe Inspector

What are the key skills required to be a successful Cooling Pipe Inspector?

The key skills required to be a successful Cooling Pipe Inspector include a strong knowledge of cooling system components and their functions, proficiency in various NDT inspection techniques, and the ability to identify and resolve cooling system issues. Other important skills include communication, teamwork, and attention to detail.

What are the career prospects for Cooling Pipe Inspectors?

The career prospects for Cooling Pipe Inspectors are good. As the demand for energy increases, so does the need for qualified Cooling Pipe Inspectors to ensure the safe and efficient operation of cooling systems. Cooling Pipe Inspectors can advance to positions such as Lead Inspector, Supervisor, or Manager.

What are the working conditions like for Cooling Pipe Inspectors?

Cooling Pipe Inspectors typically work in industrial settings, such as power plants, chemical plants, and manufacturing facilities. They may be exposed to noise, heat, and chemicals. However, most Cooling Pipe Inspectors work indoors in climate-controlled environments.

What is the average salary for Cooling Pipe Inspectors?

The average salary for Cooling Pipe Inspectors varies depending on experience, location, and employer. However, according to the U.S. Bureau of Labor Statistics, the median annual salary for Boilermakers, which includes Cooling Pipe Inspectors, was $64,980 in May 2021.

What are the educational requirements to become a Cooling Pipe Inspector?

The minimum educational requirement to become a Cooling Pipe Inspector is a high school diploma or equivalent. However, most employers prefer candidates with a post-secondary education, such as an associate degree in mechanical engineering or a related field.

What are the certification requirements to become a Cooling Pipe Inspector?

There are no specific certification requirements to become a Cooling Pipe Inspector. However, some employers may prefer candidates with certifications from organizations such as the American Society of Nondestructive Testing (ASNT).

What is the job outlook for Cooling Pipe Inspectors?

The job outlook for Cooling Pipe Inspectors is expected to be good over the next few years. As the demand for energy increases, so does the need for qualified Cooling Pipe Inspectors to ensure the safe and efficient operation of cooling systems.